Mu-Metal Foil with excellent magnetic properties

Mu-metal foil, as a precision material with excellent magnetic properties, plays an irreplaceable role in numerous high-end fields such as electronic communication, aerospace, and medical equipment. Its characteristics like high magnetic permeability and low coercivity make it an ideal choice for manufacturing high-performance magnetic components and electromagnetic shielding materials.

Abstract: This article delves into the production process of mu-metal foil, covering the entire workflow from raw material selection to finished product output. In the raw material preparation stage, strict control is imposed on high-purity iron, nickel, and other raw materials to ensure accurate proportioning. In the smelting process, advanced technologies such as vacuum induction melting are employed to guarantee the uniformity of alloy composition. Hot rolling and cold rolling are carried out in an orderly manner to gradually reduce the material thickness and optimize the structure. The critical heat treatment process, under specific temperatures and atmospheres, significantly enhances magnetic properties. Surface treatment ensures the corrosion resistance and surface quality of the foil, and finally, qualified products are obtained through finishing and slitting. All links are closely interconnected, and any minor change may have a significant impact on the magnetic and physical properties of mu-metal foil. Strict control of process parameters is the core of producing high-quality mu-metal foil.

Table of Contents

Mu-metal foil, as a precision material with excellent magnetic properties, plays an irreplaceable role in numerous high-end fields such as electronic communication, aerospace, and medical equipment. Its characteristics like high magnetic permeability and low coercivity make it an ideal choice for manufacturing high-performance magnetic components and electromagnetic shielding materials. The realization of these outstanding properties relies on a complex and precise production process. Below, we will provide a detailed interpretation of the production process of mu-metal foil.

1. Raw Material Preparation

- Selection of Raw Materials: The main components of mu-metal foil are iron (Fe) and nickel (Ni). To ensure its excellent performance, high-purity raw materials are required. The purity of iron and nickel generally needs to reach over 99.9%. For example, when producing 80Ni-20Fe type mu-metal foil, the purity of nickel must be precisely controlled at 99.95% or higher, and that of iron at 99.9% or higher. Additionally, trace elements such as molybdenum (Mo), copper (Cu), and chromium (Cr) may be added according to specific performance requirements. For instance, adding 0.5%-2% molybdenum can improve the alloy’s resistivity and hardness.

- Batching Calculation: The dosage of each raw material is determined using precise calculation methods based on the target alloy composition. For example, when producing 1J79 mu-metal foil (with a nickel content of 78.5%-79.5%, the remainder being iron, and containing a small amount of molybdenum, etc.), it is necessary to accurately calculate the input amount of each raw material according to the alloy mass and the proportion of each element to ensure minimal compositional deviation. High-precision electronic scales with an accuracy of ±0.001g are used for weighing raw materials to ensure batching accuracy.

2. Smelting

- Smelting Methods: Vacuum induction melting or arc melting technology is commonly used. In vacuum induction melting, raw materials are placed in a furnace with a vacuum degree of 10⁻³ – 10⁻⁴Pa and melted by induction heating. Taking the smelting of 80Ni-20Fe alloy as an example, the vacuum environment in the furnace can effectively reduce the incorporation of impurity gases such as oxygen and nitrogen, preventing the formation of oxide and nitride inclusions, thereby avoiding adverse effects on magnetic properties.

- Control of Smelting Process: The smelting temperature is precisely controlled, generally ranging from 1500 – 1600℃. For example, the smelting temperature of 80Ni-20Fe alloy is mostly controlled at around 1550℃ to ensure that the raw materials are fully melted and the composition is uniformly mixed. The smelting time is adjusted according to the alloy quantity and furnace type, usually 1 – 3 hours. During this period, continuous stirring is required, and electromagnetic stirring can be adopted to promote compositional homogenization.

- Casting and Forming: After smelting, the alloy liquid is cast into a specific mold to form an ingot. The thickness of the ingot is generally 10 – 50mm. For example, the ingot used for producing mu-metal foil with conventional thickness usually has a thickness of 20 – 30mm. The cooling rate during casting is controlled, and a slow cooling method is adopted (e.g., a cooling rate of 5 – 10℃/min) to reduce internal stress, shrinkage cavities, porosity, and other defects in the ingot.

3. Hot Rolling

- Heating Treatment: The ingot is heated to 800 – 1000℃. The specific temperature depends on the alloy composition. For example, mu-metal containing more alloying elements such as molybdenum requires a slightly higher heating temperature of 900 – 1000℃ to enhance material plasticity, facilitating subsequent rolling.

- Rolling Process: Multi-pass hot rolling is adopted to gradually reduce the thickness of the ingot. The reduction per pass is controlled at 10% – 30%. For example, the first pass reduction can be set at around 20%, and subsequent passes are adjusted appropriately according to the material deformation and rolling equipment capacity. Through multiple passes of hot rolling, the thickness of the ingot is reduced from the initial 10 – 50mm to 1 – 5mm, providing a blank for cold rolling.

- Optimization of Rolling Process: The rolling speed is controlled, generally ranging from 0.5 – 2m/s. Excessively high speed may lead to excessive rolling force, causing material cracking; excessively low speed affects production efficiency. Meanwhile, the surface roughness of the rolls and lubrication conditions are adjusted, and special rolling oil is used for lubrication to reduce rolling force and improve the surface quality of the sheet.

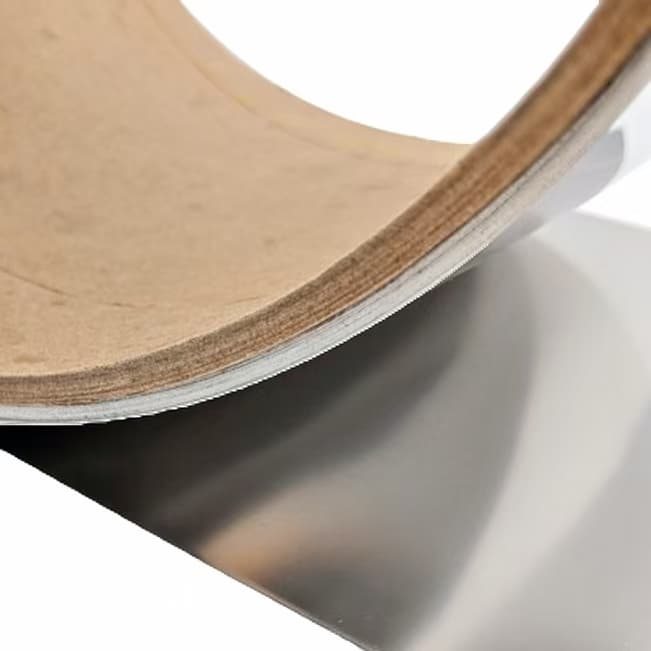

4. Cold Rolling

- Purpose and Equipment of Cold Rolling: Cold rolling is aimed at further reducing the thickness of the hot-rolled sheet to the target foil thickness (usually 0.01 – 0.1mm) and refining grains to improve material density. High-precision rolling mills, such as 20-high rolling mills, are used to achieve precise control of the foil thickness.

- Multi-pass Cold Rolling Process: Multi-pass cold rolling is performed, with the reduction per pass controlled at 5% – 20%. For example, reducing a 1mm thick hot-rolled sheet to a 0.05mm foil may require 10 – 15 passes of rolling. As the number of rolling passes increases, the work hardening degree of the material deepens, so it is necessary to reasonably adjust the rolling force and speed.

- Intermediate Annealing Treatment: Intermediate annealing is interspersed during the cold rolling process. The annealing temperature is 400 – 600℃, conducted in a vacuum or hydrogen-protected atmosphere. Intermediate annealing can eliminate work stress and restore material plasticity. For example, intermediate annealing is performed every 3 – 5 cold rolling passes to create favorable conditions for subsequent cold rolling.

- Control of Thickness and Surface Quality: The foil thickness is monitored in real-time by a high-precision thickness gauge, with the thickness tolerance controlled within ±1μm. Advanced surface treatment technologies and equipment are used to ensure the surface finish of the foil, with a surface roughness Ra ≤ 0.1μm.

5. Heat Treatment

- Purpose and Role of Annealing: Heat treatment is a key link in optimizing the magnetic properties of mu-metal foil. By annealing, the crystal structure of the alloy is adjusted to improve magnetic permeability and reduce coercivity. For example, appropriate annealing treatment can increase the magnetic permeability of 80Ni-20Fe mu-metal foil several times.

- Annealing Process Parameters: The annealing temperature is determined according to the alloy composition. For example, the annealing temperature of 80Ni-20Fe alloy is generally 1000 – 1200℃, with a typical temperature of 1100℃. It is carried out in a high-purity hydrogen atmosphere (dew point ≤ -60℃) or high vacuum environment to prevent alloy oxidation. The cooling rate is slow, usually 5 – 10℃/min. Some alloys need to undergo isothermal treatment when cooled to around 500℃ to further optimize the structure.

- Influence of Heat Treatment on Magnetic Properties: Proper heat treatment can promote the formation of ordered phases (such as Ni₃Fe) in the alloy, reduce crystal defects, and lower the resistance to domain wall movement, thereby significantly improving magnetic permeability. Studies have shown that mu-metal foil subjected to optimized heat treatment can have an initial magnetic permeability increased from 50mH/m to over 100mH/m.

6. Surface Treatment

- Removal of Oxide Layer: Pickling (e.g., a mixed solution of nitric acid and hydrofluoric acid) or electropolishing is used to remove the oxide film that may remain after heat treatment. For pickling, the pickling time and temperature are controlled to ensure that the oxide layer is removed without corroding the base material. Electropolishing achieves a smooth and flat foil surface by precisely controlling the current density and electrolyte composition.

- Corrosion Resistance Treatment: In some application scenarios, mu-metal foil is subjected to surface plating (such as nickel plating, chromium plating) or passivation treatment to improve corrosion resistance. The thickness of the nickel plating layer is generally 0.5 – 5μm, which can be applied by electroplating or electroless plating. Passivation treatment forms a passivation film on the foil surface to enhance its corrosion resistance in humid environments.

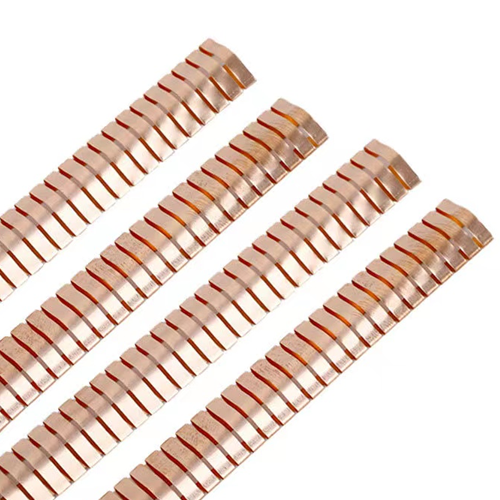

7. Finishing and Slitting

- Flattening Treatment: A precision straightening machine is used to flatten the foil to eliminate defects such as warping and waviness, ensuring the flatness of the foil. During straightening, the pressure and spacing of the straightening rolls are accurately adjusted to control the flatness error of the foil within a minimal range.

- Slitting Process: According to customer requirements, large rolls of foil are slit into coils or single sheets of specific widths. High-precision slitting equipment is used, with the slitting accuracy controlled within ±0.1mm to ensure the precise dimensions of the slit foil.

In summary, the production of mu-metal foil is a closely linked process with extremely high requirements for details. From the careful selection of raw materials to the precise control of each process, all directly affect the performance of the final product. With the continuous development of science and technology, the performance requirements for mu-metal foil will increasingly rise, which will inevitably drive continuous innovation and optimization of its production process, providing solid material support for the progress of related industries.

You May Also Like

-

Handa’s New Product:Glass Fiber Aluminum Foil Tape

Handa’s New Product:Glass Fiber Aluminum Foil TapeEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Glass Fiber Aluminum Foil Tape

🔧 Product Overview📌 Key Features & Benefits⚙️ Technical Specifications🎯 Applications🛠 Customization Options📦 Packaging & Delivery🧩 Why Choose Handa?📞 Get a Quote or Sample Handa’s Glass Fiber Aluminum Foil Tape is a high-performance insulation and sealing solution engineered for demanding industrial,......

-

Conductive Aluminium Tape: A Versatile Solution for EMI Shielding and Electrical Applications

Conductive Aluminium Tape: A Versatile Solution for EMI Shielding and Electrical ApplicationsEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Conductive aluminium tape

What Is Conductive Aluminium Tape?Key Features of Conductive Aluminium TapeCommon Applications of Conductive Aluminium Tape1. Electromagnetic Interference (EMI) and Radio-Frequency Interference (RFI) Shielding2. Cable Wrapping and Harness Protection3. Electrical Grounding4. Printed Circuit Board (PCB) Shielding5. HVAC Duct Sealing6. Automotive Electronics7.......

-

Handa Shielding TCS Dual-Wing Wire Mesh: Advanced Electromagnetic Shielding Solution

Handa Shielding TCS Dual-Wing Wire Mesh: Advanced Electromagnetic Shielding SolutionShielding Gasket Solutions and Materials

Knitted wire mesh gaskets

Handa Shielding TCS Dual-Wing Wire Mesh Core Technology: TCS Material InnovationDual-Wing Structural DesignTechnical SpecificationsApplications1. Aerospace and Defense2. Medical Devices3. Telecommunications4. Industrial ElectronicsCustomization and IntegrationPerformance AdvantagesTesting and ComplianceWhy Choose Handa Shielding? Handa Shielding’s TCS Dual-Wing Wire Mesh is a cutting-edge electromagnetic interference (EMI)......

-

Silver-plated beryllium-copper fingerstock gaskets for EMI/RFI Shielding

Silver-plated beryllium-copper fingerstock gaskets for EMI/RFI ShieldingFingerstrips

Beryllium-copper fingerstrips series

Silver-plated beryllium-copper fingerstock gaskets for EMI/RFI Shielding 1. Overview of Silver-plated beryllium-copper fingerstock gaskets2. Material and Surface Plating3. Types of Handa Shielding's Fingerstock/Fingerstrip Gaskets4. Performance Characteristics of Silver-plated beryllium-copper fingerstock gaskets5. Applications of Silver-plated beryllium-copper fingerstock gaskets6. Customization Options7. Compliance......

-

Handa Beryllium Copper Fingerstrips/Fingerstocks for High-Performance EMI/RFI Shielding

Handa Beryllium Copper Fingerstrips/Fingerstocks for High-Performance EMI/RFI ShieldingFingerstrips

Right-angle shielding fingerstrip

Handa Beryllium Copper Fingerstrips/Fingerstocks for High-Performance EMI/RFI Shielding 1. Introduction2. Material Properties of Beryllium Copper2.1. Mechanical Strength2.2. Electrical and Thermal Conductivity2.3. Corrosion and Environmental Resistance2.4. Compliance and Safety3. Design and Manufacturing Processes3.1. Material Selection3.2. Forming Techniques3.3. Surface Finishing3.4. Quality Control4.......