Conductive Aluminium Tape: A Versatile Solution for EMI Shielding and Electrical Applications

Conductive aluminium tape plays a critical role in EMI/RFI shielding, electrical grounding, and thermal management. It’s a simple yet powerful tool for ensuring performance and reliability in electronic and industrial systems. At Handa Shielding, we are committed to supplying top-tier conductive tapes that meet the high standards of today’s industries.

Table of Contents

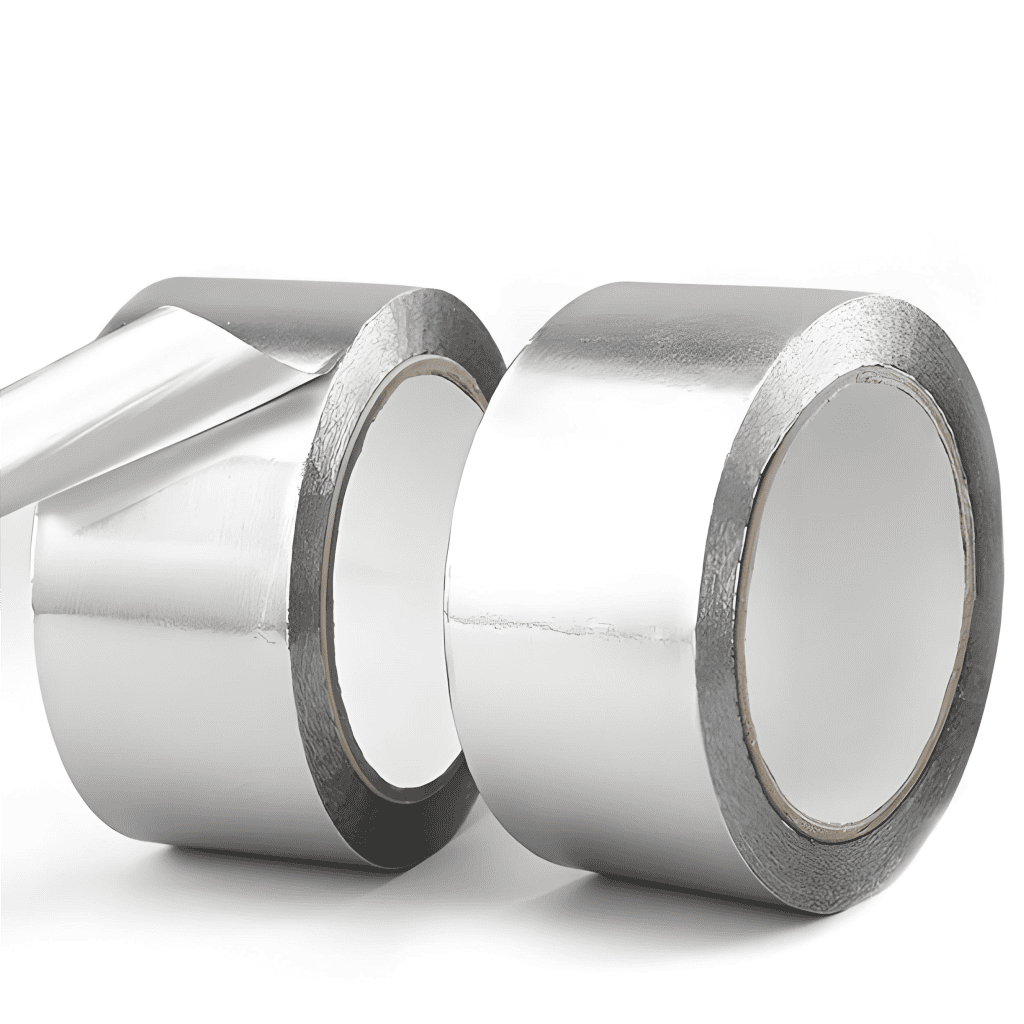

Conductive aluminium tape has become an essential component in modern electronic assembly and electromagnetic interference (EMI) shielding. Its ability to combine the conductive properties of aluminum with strong adhesive backing makes it ideal for a range of industrial, commercial, and household applications. At Handa Shielding, we manufacture and supply high-quality conductive aluminium tapes designed to deliver superior performance in demanding environments.

In this article, we’ll explore what conductive aluminium tape is, how it works, its types, applications, technical specifications, and why Handa Shielding is a trusted partner for your EMI shielding needs.

What Is Conductive Aluminium Tape?

Conductive aluminium tape, sometimes called aluminum foil tape, is a pressure-sensitive adhesive tape composed of a thin layer of aluminium foil combined with an electrically conductive adhesive. This unique construction allows the tape to perform both as a shielding material and as a conductive path for grounding and EMI protection.

The conductive adhesive ensures electrical continuity through the bonded surfaces, making the tape suitable for wrapping cables, sealing enclosures, and connecting grounding points in EMI/RFI shielding systems.

Key Features of Conductive Aluminium Tape

Here are the core properties that make conductive aluminium tape so valuable in EMI shielding and electrical applications:

- Excellent electrical conductivity on both the foil and adhesive surface

- High thermal conductivity, ideal for heat dissipation

- Strong adhesion to metals, plastics, and other materials

- Corrosion resistance with optional acrylic or solvent-based adhesive

- Flame-retardant and chemically stable under extreme conditions

- Lightweight and flexible, allowing for easy installation

- Die-cuttable into custom shapes or widths for specific projects

These features allow engineers and manufacturers to implement effective EMI/RFI shielding without the need for heavy or complex materials.

Common Applications of Conductive Aluminium Tape

Conductive aluminium tape serves a wide range of industries, from electronics and telecommunications to aerospace and automotive systems. Below are its most common applications:

1. Electromagnetic Interference (EMI) and Radio-Frequency Interference (RFI) Shielding

One of the most common uses is EMI/RFI shielding in electronic enclosures. The tape blocks or redirects electromagnetic waves to prevent signal degradation or malfunction in sensitive devices.

2. Cable Wrapping and Harness Protection

Aluminium tape is used to wrap wire harnesses and shielded cables to reduce electromagnetic noise and ensure signal integrity.

3. Electrical Grounding

Because of its conductive adhesive, the tape is excellent for providing electrical grounding paths between different components or to a chassis.

4. Printed Circuit Board (PCB) Shielding

In circuit assembly, conductive aluminium tape can be applied to PCBs to add an extra layer of EMI protection in critical zones.

5. HVAC Duct Sealing

In HVAC systems, aluminium tape seals joints in metal ducts, helping control airflow, temperature, and sound leakage. In some cases, conductive versions are used when electronic controls are involved.

6. Automotive Electronics

Used in modern vehicles to shield wiring and control modules from interference in electric and hybrid systems.

7. Aerospace and Defense Applications

Lightweight and highly durable, conductive foil tape is ideal for aircraft and defense systems requiring EMI shielding under extreme environmental conditions.

Types of Conductive Aluminium Tape Available at Handa Shielding

At Handa Shielding, we offer various types of conductive aluminium tapes to meet diverse application needs. Each tape is carefully engineered for performance, durability, and conductivity.

1. Single-Sided Conductive Aluminium Tape

This tape has a conductive adhesive on one side of the aluminium foil. It provides excellent EMI shielding when wrapped or pressed onto a surface.

- Adhesive Type: Acrylic or solvent-based conductive adhesive

- Foil Thickness: 0.03 mm to 0.08 mm

- Adhesive Resistance: ≤0.05 ohm

- Operating Temperature: -40°C to 120°C

2. Double-Sided Conductive Aluminium Tape

This type offers conductivity through both the top and bottom layers, making it ideal for multi-directional grounding or shielding applications.

- Adhesive Type: Dual conductive acrylic

- Foil Layer: Aluminum with a PET carrier (optional)

- Conductive Resistance: ≤0.03 ohm

- Use Case: PCB applications, overlapping joints

3. Reinforced Aluminium Tape

Designed for added strength and tear resistance, reinforced tapes include mesh or scrim layers, ideal for HVAC and mechanical installations.

4. Die-Cut Aluminium Foil Tape

We also provide custom die-cut solutions for specific shapes and sizes, reducing installation time and improving fit.

All tapes are RoHS-compliant and manufactured under ISO-certified quality control.

Advantages of Using Handa Shielding Conductive Aluminium Tape

Partnering with Handa Shielding ensures that you get access to world-class manufacturing and technical support. Here are the top reasons customers choose our conductive aluminium tapes:

✔ Superior Conductivity and Shielding

Our tapes offer industry-leading performance in EMI/RFI attenuation and resistive grounding, thanks to precision-engineered conductive adhesives.

✔ Customization Options

We support OEM and custom orders, including specific widths, roll lengths, die-cut pieces, and branded packaging.

✔ Excellent Adhesion & Durability

Whether you’re bonding to metal, plastic, or composite materials, our aluminium tapes maintain strong adhesion under thermal stress and vibration.

✔ Global Supply Chain

With fast lead times and international logistics support, Handa Shielding serves clients across the globe in industries including aerospace, telecom, military, and automotive.

Technical Specifications (Typical Values)

| Property | Single-Sided Tape | Double-Sided Tape |

|---|---|---|

| Foil Thickness | 0.05 mm | 0.05 mm |

| Total Thickness | 0.08 mm | 0.09 mm |

| Adhesive Type | Conductive Acrylic | Dual-Sided Conductive Acrylic |

| Surface Resistance | ≤ 0.05 ohm | ≤ 0.03 ohm |

| Adhesion to Steel | ≥ 1.5 N/cm | ≥ 1.3 N/cm |

| Temperature Range | -40°C to 120°C | -40°C to 120°C |

| RoHS/REACH Compliant | Yes | Yes |

Note: Custom specifications available upon request.

Installation and Usage Tips

To get the best performance from conductive aluminium tape, consider the following:

- Clean the surface thoroughly before application to remove dust, oil, and oxidation.

- Use a roller or squeegee to apply even pressure and ensure full contact with the adhesive.

- Avoid stretching the tape during installation, as it can weaken the foil layer.

- Overlap tape ends slightly to maintain a continuous conductive path.

- Store rolls in a dry and cool environment to preserve adhesive quality.

Why Choose Handa Shielding for Your EMI Shielding Needs?

Handa Shielding is a professional manufacturer specializing in EMI shielding materials, including:

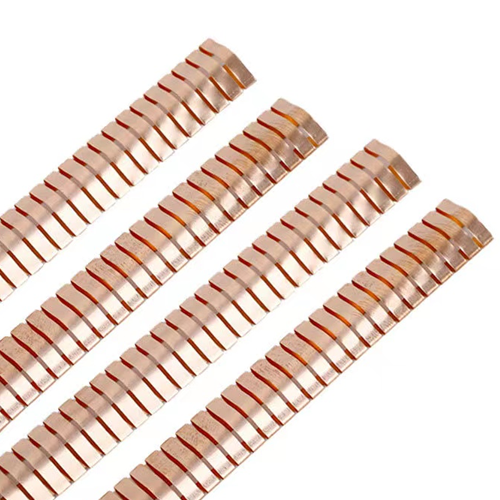

- Electromagnetic shielding spiral tubes

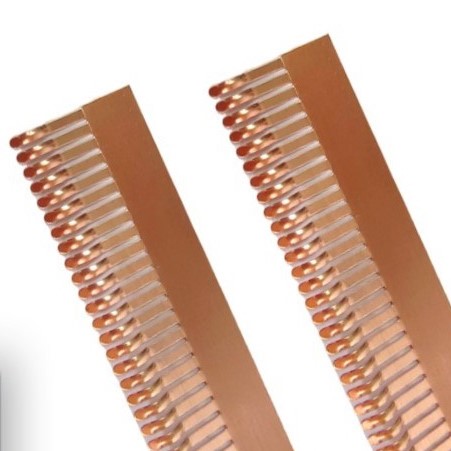

- Beryllium-copper fingerstrips

- Conductive foam and fabric

- Conductive adhesives and tapes

We offer in-house R&D, fast prototyping, and end-to-end support to help you design and implement reliable shielding solutions.

Whether you’re looking for a standard aluminium tape roll or a custom-engineered shielding kit, Handa Shielding has the technical expertise and manufacturing capacity to deliver.

FAQs About Conductive Aluminium Tape

Q1: Can aluminium tape be used as a ground?

Yes, if the tape has a conductive adhesive (like Handa Shielding’s products), it can be used for grounding in low-current or static-dissipative applications.

Q2: Is all aluminium tape conductive?

No. Some foil tapes use non-conductive adhesives. Always choose “conductive aluminium tape” with specifications that include electrical conductivity across the adhesive.

Q3: What’s the difference between copper tape and aluminium tape?

Copper has higher conductivity than aluminium but is more expensive. Aluminium tape is cost-effective and sufficient for most EMI shielding applications.

Q4: Does Handa Shielding offer custom tape widths?

Yes. We provide slitting and die-cut services to deliver tape in any width or pre-cut shape you require.

Contact Us for Custom Orders or Technical Support

Looking for a reliable source for conductive aluminium tape or other EMI shielding products? Trust Handa Shielding to deliver consistent quality, professional service, and competitive pricing.

📧 Email: qinjunchang@handashielding.com

Our engineers are available to help you select the right shielding solution for your application.

Conclusion

Conductive aluminium tape plays a critical role in EMI/RFI shielding, electrical grounding, and thermal management. It’s a simple yet powerful tool for ensuring performance and reliability in electronic and industrial systems. At Handa Shielding, we are committed to supplying top-tier conductive tapes that meet the high standards of today’s industries.

Whether you’re an OEM, electronics designer, or system integrator, our products can help you achieve optimal results in your EMI shielding strategy.

You May Also Like

-

Handa Shielding TCS Dual-Wing Wire Mesh: Advanced Electromagnetic Shielding Solution

Handa Shielding TCS Dual-Wing Wire Mesh: Advanced Electromagnetic Shielding SolutionShielding Gasket Solutions and Materials

Knitted wire mesh gaskets

Handa Shielding TCS Dual-Wing Wire Mesh Core Technology: TCS Material InnovationDual-Wing Structural DesignTechnical SpecificationsApplications1. Aerospace and Defense2. Medical Devices3. Telecommunications4. Industrial ElectronicsCustomization and IntegrationPerformance AdvantagesTesting and ComplianceWhy Choose Handa Shielding? Handa Shielding’s TCS Dual-Wing Wire Mesh is a cutting-edge electromagnetic interference (EMI)......

-

Silver-plated beryllium-copper fingerstock gaskets for EMI/RFI Shielding

Silver-plated beryllium-copper fingerstock gaskets for EMI/RFI ShieldingFingerstrips

Beryllium-copper fingerstrips series

Silver-plated beryllium-copper fingerstock gaskets for EMI/RFI Shielding 1. Overview of Silver-plated beryllium-copper fingerstock gaskets2. Material and Surface Plating3. Types of Handa Shielding's Fingerstock/Fingerstrip Gaskets4. Performance Characteristics of Silver-plated beryllium-copper fingerstock gaskets5. Applications of Silver-plated beryllium-copper fingerstock gaskets6. Customization Options7. Compliance......

-

Handa Beryllium Copper Fingerstrips/Fingerstocks for High-Performance EMI/RFI Shielding

Handa Beryllium Copper Fingerstrips/Fingerstocks for High-Performance EMI/RFI ShieldingFingerstrips

Right-angle shielding fingerstrip

Handa Beryllium Copper Fingerstrips/Fingerstocks for High-Performance EMI/RFI Shielding 1. Introduction2. Material Properties of Beryllium Copper2.1. Mechanical Strength2.2. Electrical and Thermal Conductivity2.3. Corrosion and Environmental Resistance2.4. Compliance and Safety3. Design and Manufacturing Processes3.1. Material Selection3.2. Forming Techniques3.3. Surface Finishing3.4. Quality Control4.......

-

High-Conductivity EMI Shielding Canted Coil Springs for Aerospace, Medical, and EV Systems | Dynamic Compliance & 360° Shielding Performance

High-Conductivity EMI Shielding Canted Coil Springs for Aerospace, Medical, and EV Systems | Dynamic Compliance & 360° Shielding PerformanceHanda Canted Coil Springs

EMI Shielding Springs

High-Conductivity EMI Shielding Canted Coil Springs 1. Introduction to EMI Shielding and the Role of Canted Coil Springs2. What Are Canted Coil Springs?2.1 Structural Design2.2 Material Composition3. Mechanisms of EMI Shielding in Canted Coil Springs3.1 Conductive Pathways and Grounding3.2 Synergistic......

-

Handa circular fingerstrips in electromagnetic interference (EMI) shielding

Handa circular fingerstrips in electromagnetic interference (EMI) shieldingEMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

Handa circular fingerstrips in electromagnetic interference (EMI) shielding IntroductionUnderstanding Circular FingerstripsDesign and FunctionalityApplicationsKey SpecificationsManufacturing ProcessBest Practices for Installation and MaintenanceConclusion Introduction In the realm of electromagnetic interference (EMI) shielding, Handa circular fingerstrips stand out as a pivotal component, offering robust......