Electrical Conducting Springs: The Core Component for Efficient Connections in the Power Industry

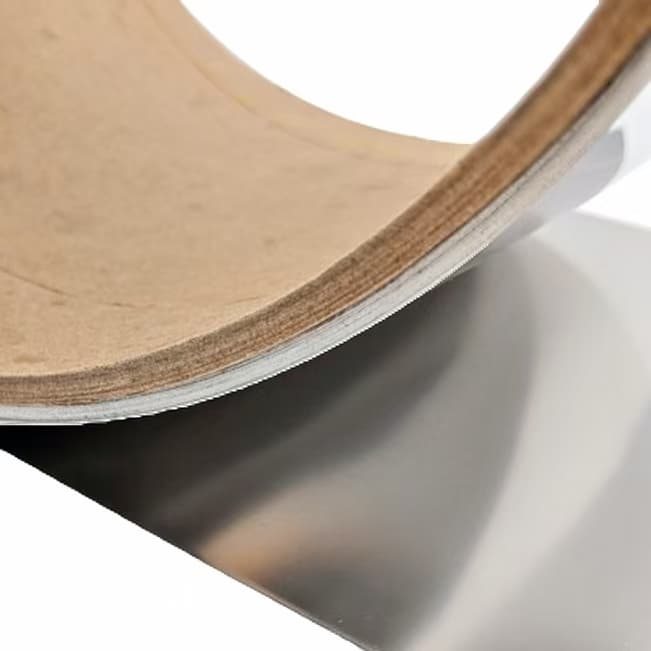

Electrical conducting springs are spiral elastic contact elements made of beryllium copper or high-conductivity alloys, typically designed with an elliptical cross-sectional coil structure. Their major axis is arranged axially to increase the contact area with static contacts and reduce contact resistance.

In high-voltage switchgear, GIS (Gas-Insulated Switchgear), and power transmission and distribution systems, electrical conducting springs have emerged as indispensable key conductive components in modern power equipment, thanks to their unique structural design and superior electrical performance. Hunan Handa Electronics Technology Co., Ltd., a leader in power connection technology, integrates cutting-edge industry research to analyze the technical advantages of electrical conducting springs and their extensive applications in the power sector.

Table of Contents

I. Technical Principles and Core Advantages of Electrical Conducting Springs

Electrical conducting springs are spiral elastic contact elements made of beryllium copper or high-conductivity alloys, typically designed with an elliptical cross-sectional coil structure. Their major axis is arranged axially to increase the contact area with static contacts and reduce contact resistance. Compared to traditional rigid contacts, their core advantages are as follows:

- Multi-point Contact and Current Sharing Design: Each turn of the spring operates independently, automatically compensating for machining tolerances. This ensures uniform current distribution, preventing localized overheating—a critical issue in high-power applications where uneven current can lead to equipment degradation or failure. For instance, in large-scale power transmission systems, even a 5% deviation in current distribution can cause a 30% increase in local temperature, but the multi-point contact design of electrical conducting springs mitigates this risk effectively.

- Self-Adjusting Pressure: Within a deformation range of 0.5~2.5mm, the springs maintain a constant contact pressure, with contact resistance varying by less than 10%. This stability far exceeds that of ordinary spring strips. Tests show that under long-term operation (over 10,000 cycles), the pressure fluctuation remains within ±5%, ensuring consistent electrical performance—a vital feature for equipment requiring high reliability, such as grid substations.

- High-Temperature Resistance and Arc Suppression: Beryllium copper combines high conductivity (electrical conductivity ≥ 20 MS/m) with excellent high-temperature resistance, operating stably in temperatures ranging from -25℃ to 105℃. Moreover, its unique material properties enable automatic arc suppression, preventing electric sparks that could ignite insulation materials or cause short circuits. This makes it ideal for high-voltage environments where arc hazards are prevalent.

- Compact Design: With small volume and light weight, these springs fit the compact structural requirements of high-voltage switches, reducing the overall size and cost of equipment. For example, in GIS systems, the use of electrical conducting springs has reduced the equipment footprint by up to 20% compared to traditional rigid contact designs.

II. Typical Application Scenarios in the Power Industry

1. High-Voltage Switchgear

In 220~500kV high-voltage switches, electrical conducting springs act as intermediate connectors between moving and static contacts, providing stable contact pressure through elastic deformation. A case study from a domestic power company illustrates their impact: after adopting customized beryllium copper electrical conducting springs, the company saw a 40% reduction in equipment downtime and a 30% drop in maintenance costs. This is attributed to the springs’ ability to withstand frequent switching operations without performance degradation. For higher voltage levels (e.g., 750kV and 1000kV), the springs’ arc-suppression capability becomes even more critical, ensuring safe operation during high-current interruptions.

2. GIS/GIL Systems

Gas-Insulated Switchgear (GIS) and Gas-Insulated Transmission Lines (GIL) rely on electrical conducting springs for sliding electrical contact. Their vibration resistance (withstanding frequencies up to 50Hz with minimal performance loss) and dustproof properties (meeting IP65 protection standards) make them suitable for harsh environments, such as coastal areas with high humidity or industrial zones with heavy particulate matter. This reliability ensures long-term operation—some installations have maintained stable performance for over 20 years with minimal maintenance.

3. 10kV Distribution Equipment

The Zhongshan Power Supply Bureau developed a dedicated electrical conducting spring replacement device, reducing operation time from 10.7 minutes to 2 minutes. This innovation not only improved work efficiency but also avoided heating risks caused by damage to contact plating—a common issue with traditional replacement methods. The achievement won the National Quality Innovation First Prize, highlighting its industry impact.

4. Intelligent Upgrade of Isolators

New smart contacts use nickel-titanium shape memory alloy spring strips instead of traditional materials. These alloys recover their original shape when heated, solving the failure problem caused by spring overheating. In field tests, this upgrade reduced power accidents related to contact failure by 60%, significantly enhancing grid stability. The memory alloy’s responsiveness (actuating within 2 seconds of temperature rise) ensures rapid adjustment to changing load conditions.

III. Technical Empowerment by Handa Electronics

Hunan Hand 达 Electronics Technology Co., Ltd. provides tailored technical support to meet the specific needs of the power industry:

- Customized Solutions: Designs spring parameters (e.g., coil diameter, number of turns, and elliptical ratio) based on actual operating conditions, and meets plating requirements (gold or silver plating, with thickness ranging from 0.5μm to 5μm) to enhance conductivity and corrosion resistance.

- Process Assurance: Adopts laser welding and aging heat treatment processes. Laser welding ensures flat, burr-free solder joints, minimizing the risk of high-voltage discharge. Aging heat treatment (conducted at 300~350℃ for 2~4 hours) optimizes the material’s mechanical properties, ensuring long-term elasticity.

- Quality Verification: Products pass dynamic and thermal stability tests, meeting the requirement of 10,000 mechanical operations. They also comply with international standards such as IEC 62271-100 (for high-voltage switches) and GB/T 11022 (for general technical conditions of power equipment), providing customers with reliable quality assurance.

IV. Future Trends: Green and Intelligent Development

As new energy power stations and smart grids develop, electrical conducting springs will evolve in two key directions:

- Higher Current-Carrying Capacity: With the growth of new energy vehicle charging modules and high-power renewable energy systems, springs will be designed to handle higher currents (up to 5000A) while maintaining low contact resistance. This requires advancements in material science, such as the development of copper-based composites with enhanced conductivity and heat dissipation.

- Integration with Sensors: Future springs may integrate micro-sensors (e.g., temperature and pressure sensors) to monitor contact status in real-time. Data transmission via wireless networks will enable predictive maintenance, allowing operators to address potential issues before failures occur. This aligns with the smart grid’s demand for real-time monitoring and intelligent decision-making.

In addition, green materials will gain traction. Research into beryllium-free alloys (e.g., copper-tin alloys) is underway to reduce environmental and health risks associated with beryllium, supporting sustainable development in the power industry.

Conclusion

The technological progress of electrical conducting springs directly drives the performance improvement of power equipment. Choosing a professional supplier ensures lower operation and maintenance costs and a longer equipment lifecycle. To learn more about Handa Electronics’ (handashielding) electrical conducting spring solutions, please contact our technical team(kathy@handashielding.com).

We are committed to innovating alongside the power industry, contributing to efficient and safe operation of power equipment worldwide.

You May Also Like

-

Conductive Cloth Tape: Structure, Uses, Characteristics & Buying Guide

Conductive Cloth Tape: Structure, Uses, Characteristics & Buying GuideEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Conductive Cloth Tape

Against the backdrop of the rapid development of modern electronic information technology, various electronic devices are emerging in an endless stream, and the electromagnetic environment is becoming increasingly complex. Electromagnetic interference not only affects the normal operation of equipment but......

-

Mu-Metal Foil with excellent magnetic properties

Mu-Metal Foil with excellent magnetic propertiesEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Mu-ferro/mu-metal foil

Abstract: This article delves into the production process of mu-metal foil, covering the entire workflow from raw material selection to finished product output. In the raw material preparation stage, strict control is imposed on high-purity iron, nickel, and other raw......

-

Handa’s New Product:Glass Fiber Aluminum Foil Tape

Handa’s New Product:Glass Fiber Aluminum Foil TapeEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Glass Fiber Aluminum Foil Tape

🔧 Product Overview📌 Key Features & Benefits⚙️ Technical Specifications🎯 Applications🛠 Customization Options📦 Packaging & Delivery🧩 Why Choose Handa?📞 Get a Quote or Sample Handa’s Glass Fiber Aluminum Foil Tape is a high-performance insulation and sealing solution engineered for demanding industrial,......

-

Conductive Aluminium Tape: A Versatile Solution for EMI Shielding and Electrical Applications

Conductive Aluminium Tape: A Versatile Solution for EMI Shielding and Electrical ApplicationsEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Conductive aluminium tape

What Is Conductive Aluminium Tape?Key Features of Conductive Aluminium TapeCommon Applications of Conductive Aluminium Tape1. Electromagnetic Interference (EMI) and Radio-Frequency Interference (RFI) Shielding2. Cable Wrapping and Harness Protection3. Electrical Grounding4. Printed Circuit Board (PCB) Shielding5. HVAC Duct Sealing6. Automotive Electronics7.......

-

Handa Shielding TCS Dual-Wing Wire Mesh: Advanced Electromagnetic Shielding Solution

Handa Shielding TCS Dual-Wing Wire Mesh: Advanced Electromagnetic Shielding SolutionShielding Gasket Solutions and Materials

Knitted wire mesh gaskets

Handa Shielding TCS Dual-Wing Wire Mesh Core Technology: TCS Material InnovationDual-Wing Structural DesignTechnical SpecificationsApplications1. Aerospace and Defense2. Medical Devices3. Telecommunications4. Industrial ElectronicsCustomization and IntegrationPerformance AdvantagesTesting and ComplianceWhy Choose Handa Shielding? Handa Shielding’s TCS Dual-Wing Wire Mesh is a cutting-edge electromagnetic interference (EMI)......