High-Performance Conductive Fabric for EMI Shielding in Electronics and Communication Equipment

- Model Number: Shielding conductive fabric cloth

- Colour: Black, gray, silver

Table of Contents

1. Introduction to Conductive Fabric

At Handa Shielding, our conductive fabric delivers high-performance electromagnetic interference (EMI) shielding and grounding solutions for the fast-evolving electronics and communication industries.

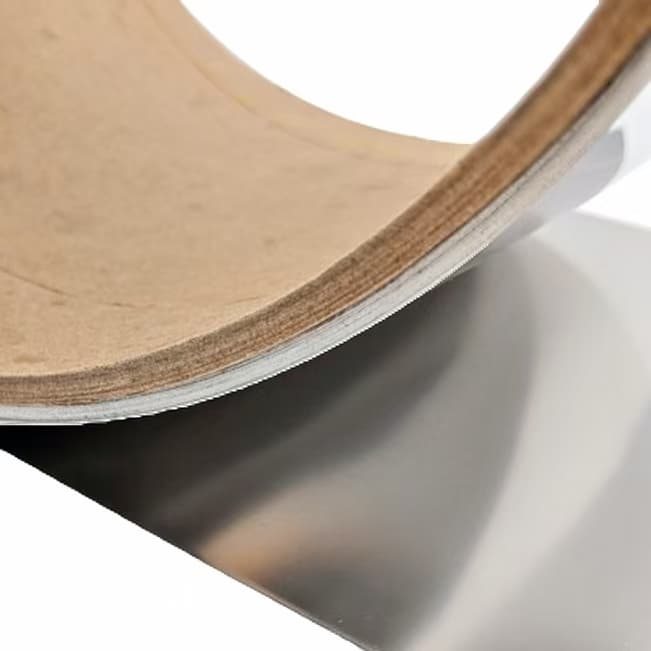

Conductive fabric is a metal-coated textile that combines the flexibility of fabric with the electrical performance of metals such as copper, nickel, or silver. It effectively absorbs and reflects electromagnetic radiation to prevent signal leakage, crosstalk, and electronic failure.

According to Grand View Research (2024), the global conductive textile market reached USD 3.61 billion and is projected to grow to USD 7.20 billion by 2033, driven by 5G infrastructure, electric vehicles, and wearable electronics.

| Product Details | |

| Function | Antistatic, anti radiation, electromagnetic wave blocking |

| Knitted Type | Warp |

| Technics | knitted |

| Pattern | Plating, Plain, Grid, Diamond, Single black, Double black |

| Product Type | Other Fabric, Shielding conductive fabric cloth |

| Width | 1100mm、1300mm、650mm、1080mm、1080mm±10mm |

| Weight | 70g, 80±10 g/sqm |

| Thickness | light weight |

| Color | Grey, Silver, Black |

| Material | Polyester, Polyester fiber+copper-Nickel |

| Specific use | Industry, Tents, Bags, Meternity clothes, Curtains, Special uniforms |

| Place of Origin | China |

2. Key Performance Advantages

Handa Shielding’s conductive fabric provides a superior combination of shielding efficiency, flexibility, and long-term stability:

- High Shielding Effectiveness: 10MHz~3GHz ≥60dB .

- Low Surface Resistivity: ≤ 0.05 Ω/□ for excellent current conduction.

- Lightweight & Flexible: 60 % lighter than copper foil, easily conforms to irregular surfaces.

- Corrosion Resistance: Nickel and silver coatings maintain conductivity under humidity.

- Durability: Retains > 90 % performance after 100 bending cycles (MDPI Textiles Research 2023).

These features make our conductive fabric ideal for sensitive devices requiring high-frequency EMI/RFI shielding and stable grounding performance.

3. Applications in Electronics and Communication

Our conductive fabric is widely used in high-performance sectors requiring precision shielding and grounding.

3.1 Consumer and Industrial Electronics

Used inside smartphones, tablets, PCs, and power modules to suppress EMI and maintain signal integrity. The fabric can line device housings, cables, or connectors.

3.2 5G and Telecommunication Systems

In 5G base stations and routers, electromagnetic interference can disrupt data transfer. Conductive fabric wraps, tapes, and gasket linings reduce interference and enhance stability .

3.3 Automotive Electronics

Electric and hybrid vehicles contain multiple control units and high-voltage lines. Our conductive fabric shields battery systems, radar sensors, and infotainment modules from EMI.

3.4 Aerospace and Defense

Used in aircraft and satellite systems for lightweight EMI shielding and anti-static protection. It replaces traditional metal foils, reducing weight while maintaining effectiveness.

3.5 Wearable and Medical Devices

Flexible conductive textiles enable biosignal monitoring and heating functions in smart garments while maintaining comfort and conductivity after washing.

4. Technical Specifications

| Property | Typical Value | Reference / Source |

|---|---|---|

| Base Material | Polyester / Nylon | Shieldex.de |

| Coating Metal | Copper, Nickel, Silver | Industry Standard |

| Surface Resistivity | ≤ 0.05 Ω/□ | MDPI 2023 Study |

| Shielding Effectiveness | 60–90 dB (30 MHz – 30 GHz) | Noble Biomaterials |

| Thickness | 0.05 – 0.10 mm | Nano3D Systems |

| Weight | 80 – 120 g/m² | Market Data |

| Temperature Range | -40 °C to +120 °C | Manufacturer Testing |

| Durability | > 90 % SE after 100 bending cycles | MDPI 2023 Research |

These specifications ensure our conductive fabric meets the requirements of high-reliability EMI control in complex electronic systems.

5. Why Choose Handa Shielding

At Handa Shielding, we don’t just supply conductive fabric — we deliver complete EMI shielding solutions:

- Customization: Available in rolls, adhesive-backed sheets, or laminated gaskets.

- Advanced Coatings: Copper-nickel, silver, or hybrid multi-metal coatings.

- Precision Cutting: Die-cut and CNC processing for exact component fit.

- Global Support: ISO-certified production with technical consulting and fast delivery.

- Full Material Integration: Compatible with other Handa Shielding products such as EMI Shielding Gaskets and Shielding Spiral Tubes.

7. Conclusion

As the demand for compact, high-speed electronic systems continues to rise, reliable EMI shielding materials become essential. Handa Shielding’s conductive fabric provides high shielding effectiveness, outstanding flexibility, and proven durability across electronics, communication, automotive, aerospace, and wearable technologies.

For more information, visit Handashielding to explore our full range of EMI shielding materials and request a customized quote.

You May Also Like

-

Electrical Conducting Springs: The Core Component for Efficient Connections in the Power Industry

Electrical Conducting Springs: The Core Component for Efficient Connections in the Power IndustryHanda Canted Coil Springs

Electrical conducting springs

In high-voltage switchgear, GIS (Gas-Insulated Switchgear), and power transmission and distribution systems, electrical conducting springs have emerged as indispensable key conductive components in modern power equipment, thanks to their unique structural design and superior electrical performance. Hunan Handa Electronics Technology......

-

Conductive Cloth Tape: Structure, Uses, Characteristics & Buying Guide

Conductive Cloth Tape: Structure, Uses, Characteristics & Buying GuideEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Conductive Cloth Tape

Against the backdrop of the rapid development of modern electronic information technology, various electronic devices are emerging in an endless stream, and the electromagnetic environment is becoming increasingly complex. Electromagnetic interference not only affects the normal operation of equipment but......

-

Mu-Metal Foil with excellent magnetic properties

Mu-Metal Foil with excellent magnetic propertiesEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Mu-ferro/mu-metal foil

Abstract: This article delves into the production process of mu-metal foil, covering the entire workflow from raw material selection to finished product output. In the raw material preparation stage, strict control is imposed on high-purity iron, nickel, and other raw......

-

Handa’s New Product:Glass Fiber Aluminum Foil Tape

Handa’s New Product:Glass Fiber Aluminum Foil TapeEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Glass Fiber Aluminum Foil Tape

🔧 Product Overview📌 Key Features & Benefits⚙️ Technical Specifications🎯 Applications🛠 Customization Options📦 Packaging & Delivery🧩 Why Choose Handa?📞 Get a Quote or Sample Handa’s Glass Fiber Aluminum Foil Tape is a high-performance insulation and sealing solution engineered for demanding industrial,......

-

Conductive Aluminium Tape: A Versatile Solution for EMI Shielding and Electrical Applications

Conductive Aluminium Tape: A Versatile Solution for EMI Shielding and Electrical ApplicationsEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Conductive aluminium tape

What Is Conductive Aluminium Tape?Key Features of Conductive Aluminium TapeCommon Applications of Conductive Aluminium Tape1. Electromagnetic Interference (EMI) and Radio-Frequency Interference (RFI) Shielding2. Cable Wrapping and Harness Protection3. Electrical Grounding4. Printed Circuit Board (PCB) Shielding5. HVAC Duct Sealing6. Automotive Electronics7.......