Conductive Cloth Tape: Structure, Uses, Characteristics & Buying Guide

conductive cloth tape plays a vital role in many fields with its unique structure and excellent performance. With the continuous progress of science and technology and the increasing requirements for the performance of electronic equipment, the application prospect of conductive cloth tape will be broader, and its performance will continue to be optimized and improved, providing more powerful support for the development of various industries.

Against the backdrop of the rapid development of modern electronic information technology, various electronic devices are emerging in an endless stream, and the electromagnetic environment is becoming increasingly complex. Electromagnetic interference not only affects the normal operation of equipment but may also damage its performance and service life. Moreover, the stability of electrical connections such as grounding is the foundation for the reliable operation of equipment. Under such demands, conductive cloth tape, with its unique structure and excellent performance, has become one of the key materials to solve the above problems.

Abstract

Conductive cloth tape is composed of a fabric backing, conductive coating, adhesive, and release paper or release film. It possesses characteristics such as good conductivity, excellent electromagnetic shielding performance, and abrasion resistance. It is widely used in multiple fields including electronic device manufacturing, communications, and automotive electronics. There are many precautions for its use and storage, making it an indispensable important material in modern industry.

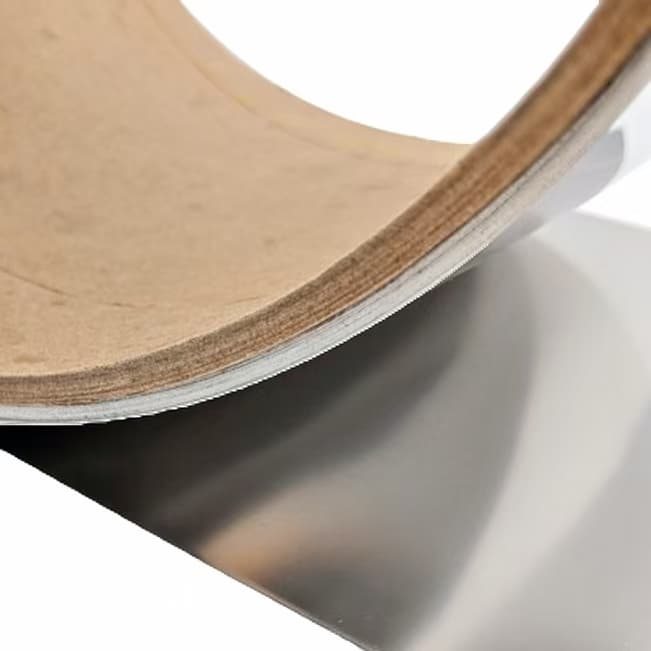

Structure and Composition of conductive cloth tape

- Fabric backing: Usually made of woven polyester fiber or cotton materials, it provides flexibility and mechanical strength, and can adapt to the pasting needs of different shapes and surfaces.

- Conductive coating: A layer of conductive metal, such as nickel and copper, is covered on the fabric surface through processes like electroplating or coating, enabling the tape to have good conductivity and electromagnetic shielding performance.

- Adhesive: Generally, there are types such as conductive acrylic adhesive and hot-melt adhesive, which are used to fix the conductive cloth in the required position and ensure a good electrical connection with the pasted object. Some high-performance conductive cloth tapes use conductive adhesives containing metal particles to enhance conductivity and shielding effect.

- Release paper or release film: Covered on the surface of the adhesive, it protects the adhesive from contamination before use, facilitates the storage and transportation of the tape, and can be torn off when in use.

Characteristics of conductive cloth tape

- Good conductivity: It can provide a low-resistance path for current, ensuring stable and reliable electrical connections inside electronic devices, and meeting functional requirements such as grounding and shielding.

- Excellent electromagnetic shielding performance: It can effectively block or attenuate electromagnetic interference (EMI) and radio frequency interference (RFI), preventing electronic devices from being affected by external electromagnetic waves, and at the same time, avoiding electromagnetic waves generated by the device itself from interfering with other components or surrounding equipment.

- Good abrasion resistance: The specially treated conductive cloth tape has a high number of abrasion resistance cycles, such as 5,000,000 times (NF35B050, ASTM D 4966). It is not easy to be damaged due to friction during use, ensuring the service life and performance stability of the tape.

- Good metal adhesion and Z-direction conductivity: It can firmly bond with metal surfaces and has good conductivity in the direction perpendicular to the tape plane (Z-direction), ensuring the electrical connection effect in different directions.

- Good processability: It is soft in texture, easy to cut and slit, and has no burrs after slitting, which is convenient for customized processing according to different application scenarios and needs. In addition, it has anti-fingerprint contamination and anti-oxidation treatment to keep the surface of the tape clean and performance stable.

Application Fields of conductive cloth tape

- Electronic device manufacturing: Used for internal shielding and grounding of electronic products such as computers, mobile phones, tablets, and laptops, such as display bezels, circuit boards, and battery modules. It can effectively reduce electromagnetic interference and improve the stability and reliability of the equipment.

- Communication field: In devices such as communication base stations, routers, and switches, it is used to shield electromagnetic interference, ensure stable signal transmission, and improve communication quality.

- Automotive electronics: Applied to components such as automotive electronic control systems, in-vehicle entertainment systems, and sensors, it prevents electromagnetic interference from affecting automotive electronic equipment, ensuring the safe operation of the car and the normal realization of various functions.

- Aerospace and national defense: In aerospace and national defense equipment such as aircraft, satellites, and radars, it is used for electromagnetic shielding and grounding to ensure the reliable operation of equipment in complex electromagnetic environments.

- Wires and cables: It can be used for the repair of the shielding layer of wires and cables, the enhancement and shielding of connection parts, preventing signal leakage and external interference, and improving the transmission performance of cables.

Precautions for Use and Storage of conductive cloth tape

- Temperature recovery before use: When used in a low-magnetic natural environment, the tape needs to be warmed up to room temperature (about 20°C) for more than three hours to ensure the adhesiveness, conductivity, and other properties of the tape.

- Packaging and storage: Conductive cloth tape products are usually packaged with wrapping paper or shrink film and placed in appropriate cartons. They should be stored in a cool place, avoiding high temperature or high humidity environments to prevent the performance of the tape from being affected.

- Shelf life: Generally speaking, the quality guarantee period of conductive cloth tape is about 6 months after production, and it should be used within the shelf life to ensure that its performance meets the requirements.

To sum up, conductive cloth tape plays a vital role in many fields with its unique structure and excellent performance. With the continuous progress of science and technology and the increasing requirements for the performance of electronic equipment, the application prospect of conductive cloth tape will be broader, and its performance will continue to be optimized and improved, providing more powerful support for the development of various industries.

You May Also Like

-

Mu-Metal Foil with excellent magnetic properties

Mu-Metal Foil with excellent magnetic propertiesEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Mu-ferro/mu-metal foil

Abstract: This article delves into the production process of mu-metal foil, covering the entire workflow from raw material selection to finished product output. In the raw material preparation stage, strict control is imposed on high-purity iron, nickel, and other raw......

-

Handa’s New Product:Glass Fiber Aluminum Foil Tape

Handa’s New Product:Glass Fiber Aluminum Foil TapeEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Glass Fiber Aluminum Foil Tape

🔧 Product Overview📌 Key Features & Benefits⚙️ Technical Specifications🎯 Applications🛠 Customization Options📦 Packaging & Delivery🧩 Why Choose Handa?📞 Get a Quote or Sample Handa’s Glass Fiber Aluminum Foil Tape is a high-performance insulation and sealing solution engineered for demanding industrial,......

-

Conductive Aluminium Tape: A Versatile Solution for EMI Shielding and Electrical Applications

Conductive Aluminium Tape: A Versatile Solution for EMI Shielding and Electrical ApplicationsEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Conductive aluminium tape

What Is Conductive Aluminium Tape?Key Features of Conductive Aluminium TapeCommon Applications of Conductive Aluminium Tape1. Electromagnetic Interference (EMI) and Radio-Frequency Interference (RFI) Shielding2. Cable Wrapping and Harness Protection3. Electrical Grounding4. Printed Circuit Board (PCB) Shielding5. HVAC Duct Sealing6. Automotive Electronics7.......

-

Handa Shielding TCS Dual-Wing Wire Mesh: Advanced Electromagnetic Shielding Solution

Handa Shielding TCS Dual-Wing Wire Mesh: Advanced Electromagnetic Shielding SolutionShielding Gasket Solutions and Materials

Knitted wire mesh gaskets

Handa Shielding TCS Dual-Wing Wire Mesh Core Technology: TCS Material InnovationDual-Wing Structural DesignTechnical SpecificationsApplications1. Aerospace and Defense2. Medical Devices3. Telecommunications4. Industrial ElectronicsCustomization and IntegrationPerformance AdvantagesTesting and ComplianceWhy Choose Handa Shielding? Handa Shielding’s TCS Dual-Wing Wire Mesh is a cutting-edge electromagnetic interference (EMI)......

-

Silver-plated beryllium-copper fingerstock gaskets for EMI/RFI Shielding

Silver-plated beryllium-copper fingerstock gaskets for EMI/RFI ShieldingFingerstrips

Beryllium-copper fingerstrips series

Silver-plated beryllium-copper fingerstock gaskets for EMI/RFI Shielding 1. Overview of Silver-plated beryllium-copper fingerstock gaskets2. Material and Surface Plating3. Types of Handa Shielding's Fingerstock/Fingerstrip Gaskets4. Performance Characteristics of Silver-plated beryllium-copper fingerstock gaskets5. Applications of Silver-plated beryllium-copper fingerstock gaskets6. Customization Options7. Compliance......