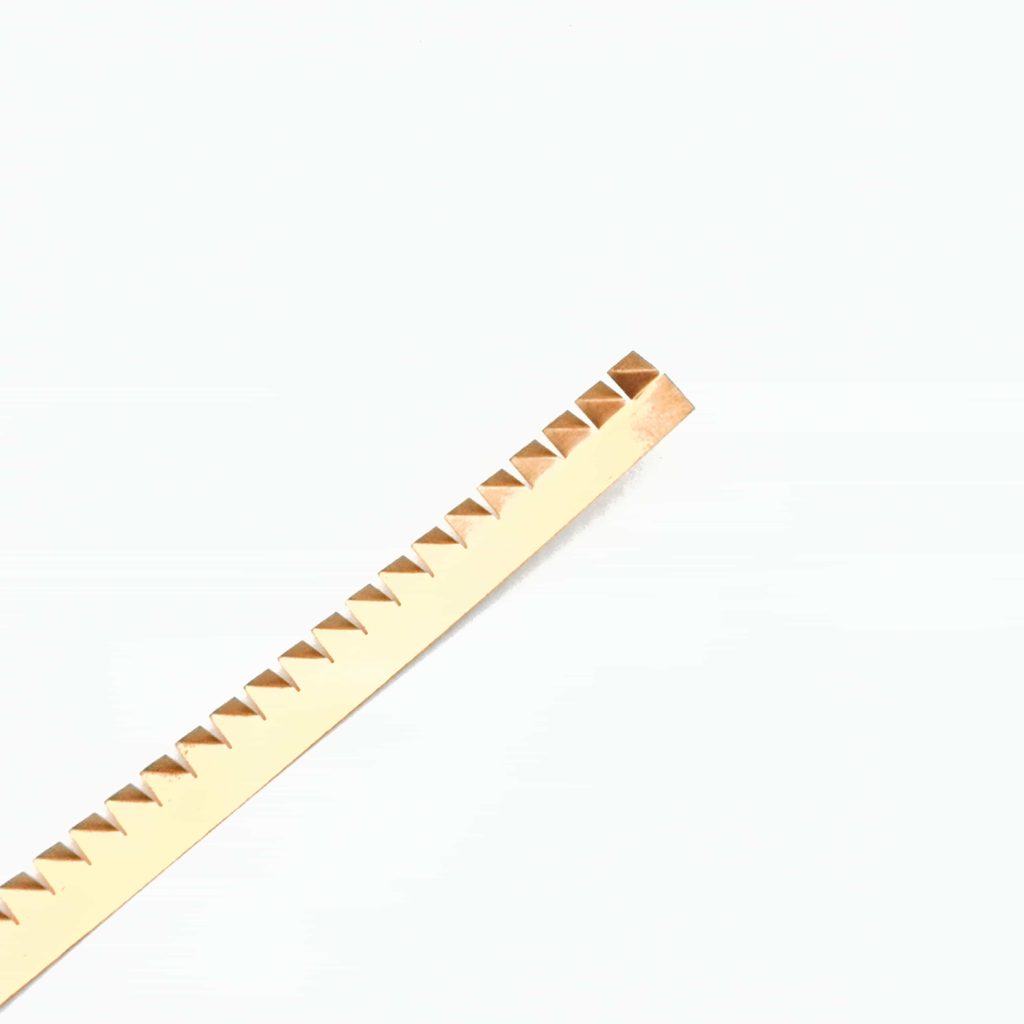

Flexible and Conductive Twisted Mounting Shielding Fingerstrips

Twisted mounting shielding fingerstrips are flexible and conductive gaskets engineered for EMI shielding. Their distinguishing feature is their unique twisted design, which enables them to maintain consistent contact with surfaces, even those that are irregular or uneven.

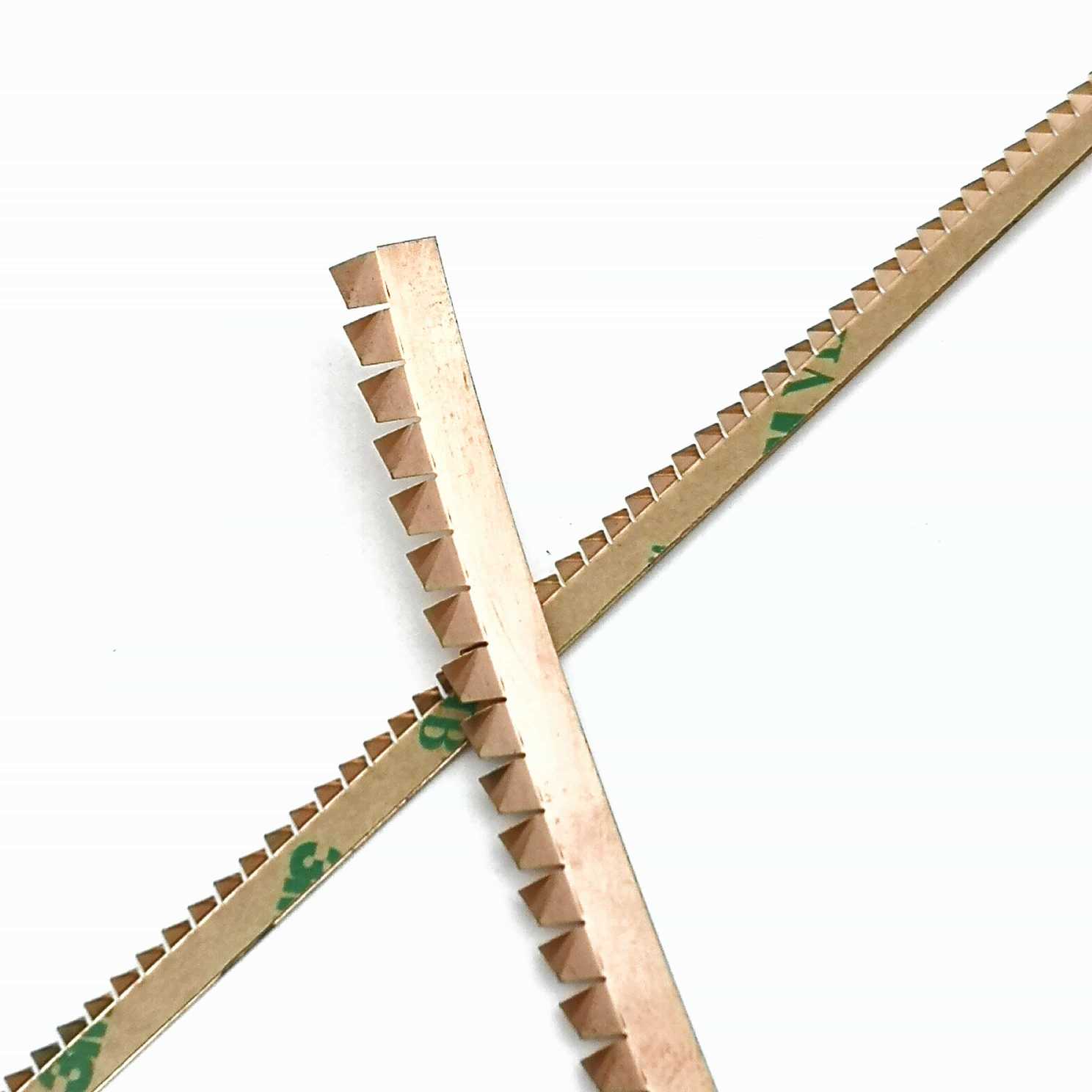

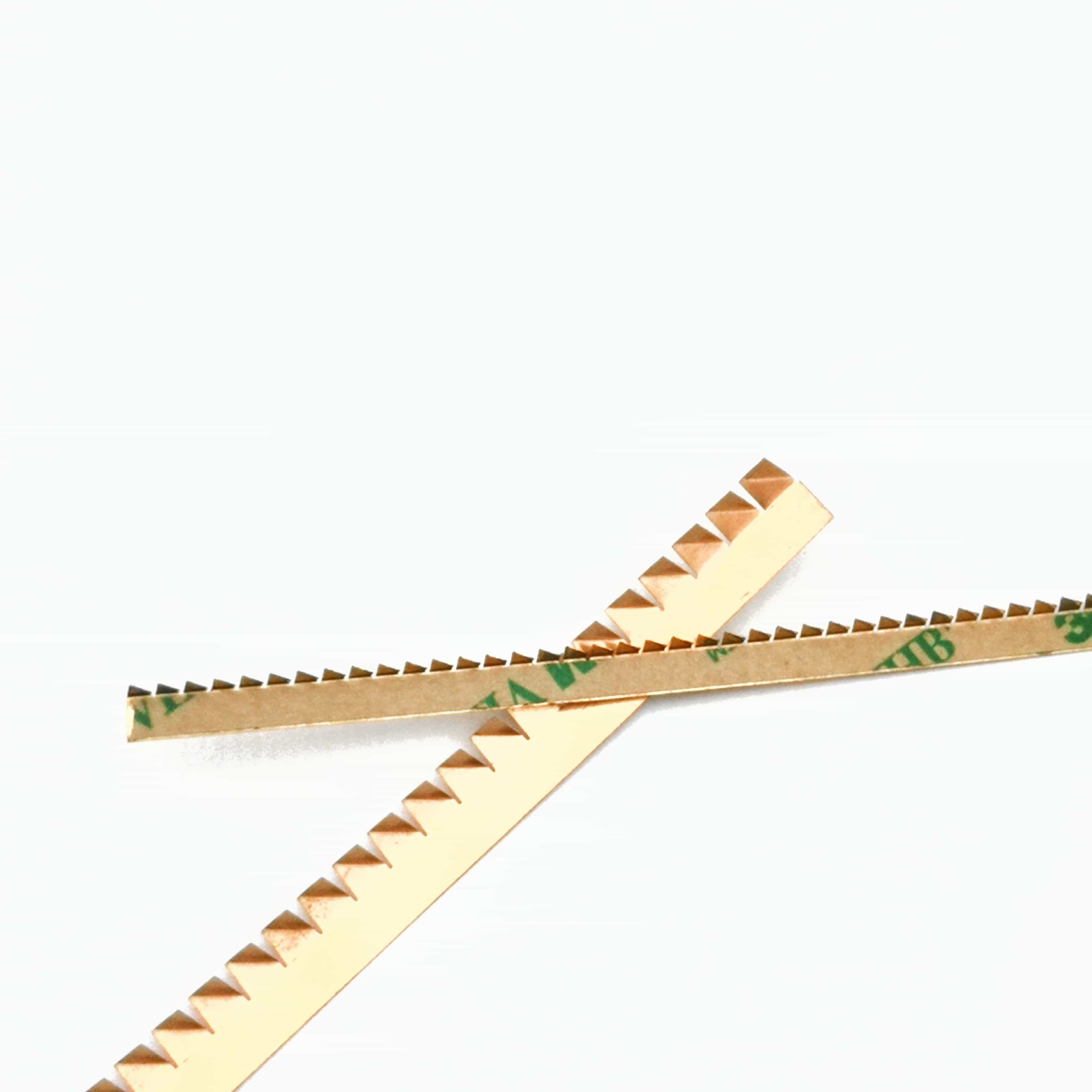

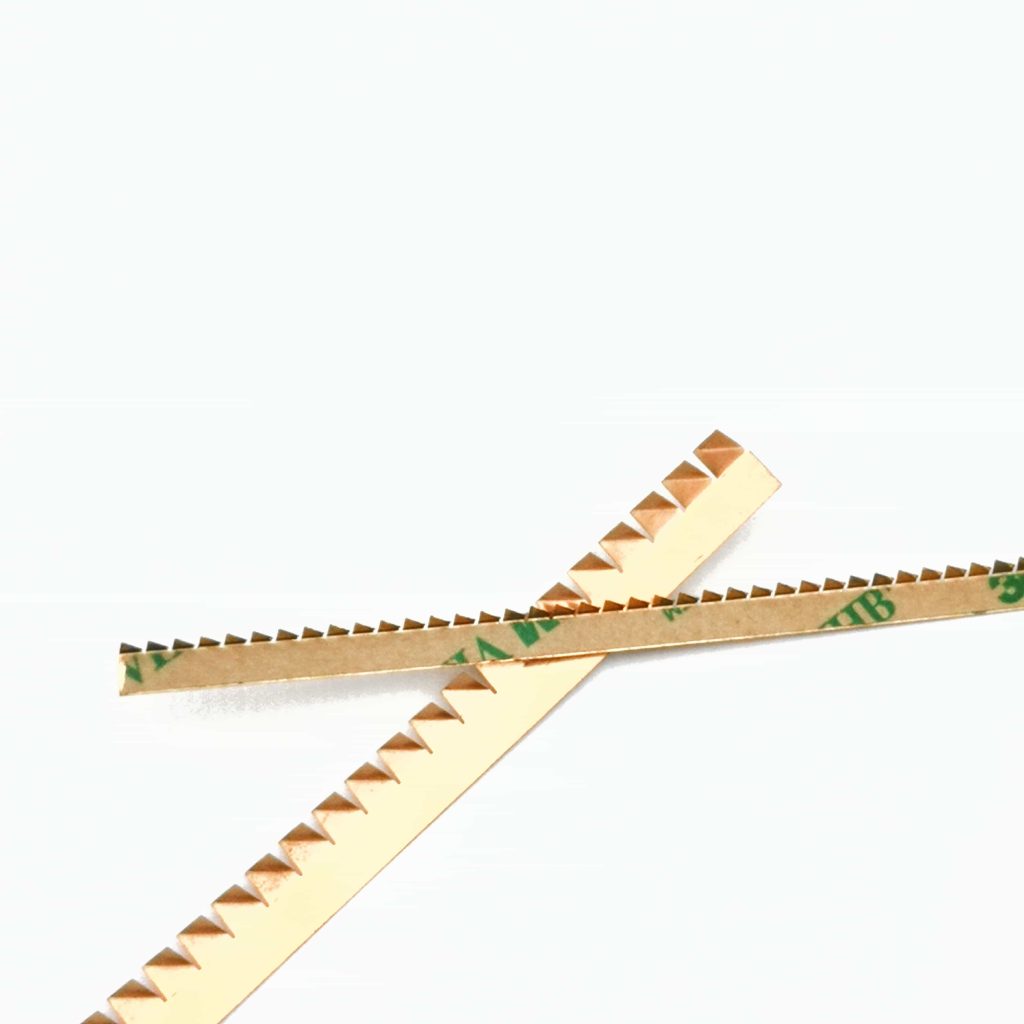

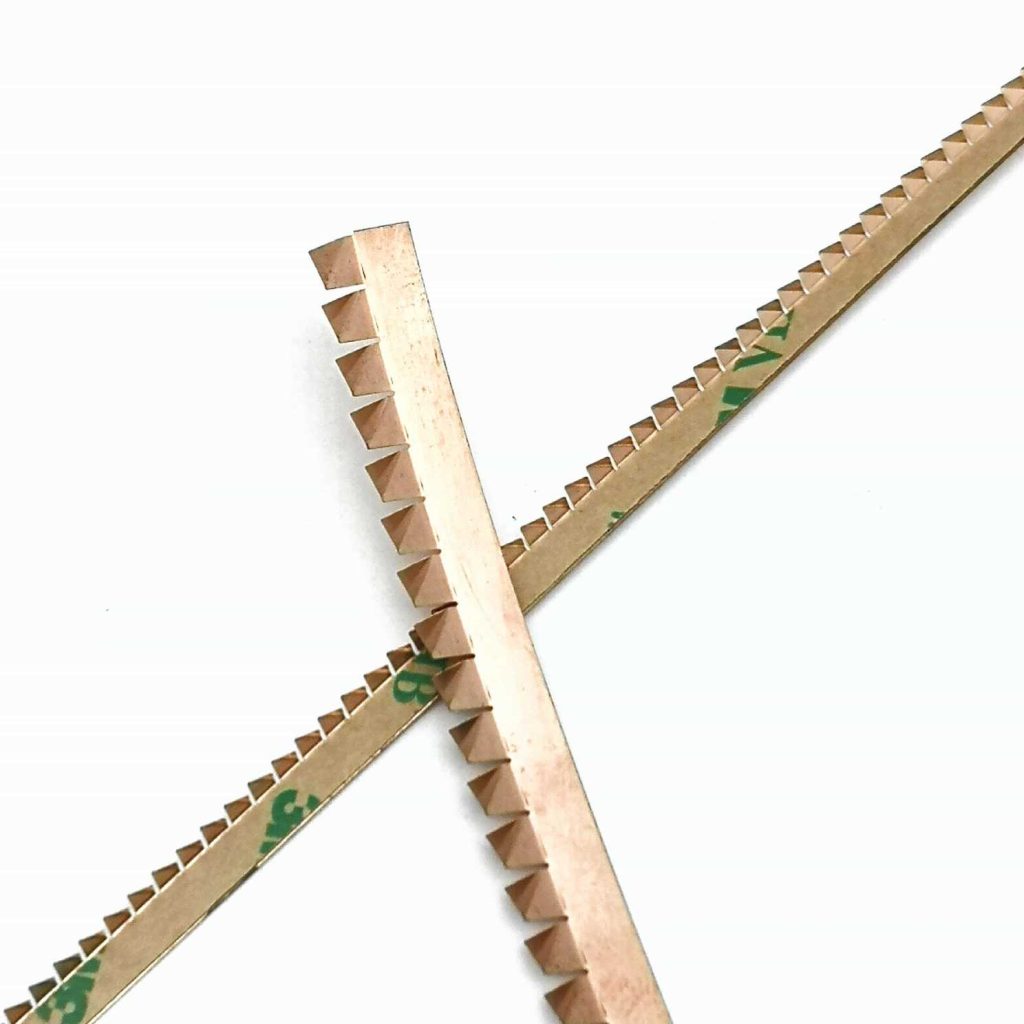

Twisted mounting shielding fingerstrips

Table of Contents

Introduction

In the world of electronic devices and systems, the demand for effective electromagnetic interference (EMI) shielding is more pressing than ever. As electronics become more compact and powerful, their susceptibility to EMI grows, potentially jeopardizing the reliability and performance of critical systems. Twisted mounting shielding fingerstrips stand out as an innovative solution to these challenges.

These components are specifically designed to provide robust EMI shielding while offering versatility in installation and adaptability to various surface profiles. Whether used in telecommunications, aerospace, or consumer electronics, twisted mounting shielding fingerstrips deliver exceptional performance and durability.

This comprehensive guide explores the design, functionality, material composition, benefits, and applications of twisted mounting shielding fingerstrips, shedding light on why they are a preferred choice for many industries.

What are Twisted Mounting Shielding Fingerstrips?

Twisted mounting shielding fingerstrips are flexible and conductive gaskets engineered for EMI shielding. Their distinguishing feature is their unique twisted design, which enables them to maintain consistent contact with surfaces, even those that are irregular or uneven.

These fingerstrips are typically fabricated from materials such as beryllium copper or stainless steel and are coated with conductive plating materials like tin, nickel, or silver. This combination of materials ensures excellent electrical conductivity, mechanical resilience, and resistance to environmental factors such as corrosion and wear.

The versatility of twisted mounting shielding fingerstrips makes them ideal for use in a variety of enclosures, seams, and openings where EMI shielding and grounding are required.

Key Features

1. Twisted Design for Maximum Flexibility

The twisted construction of these shielding fingerstrips is what sets them apart. This design enables them to:

- Adapt to irregular surfaces.

- Provide uniform contact pressure.

- Accommodate large tolerances without compromising shielding performance.

2. Exceptional Electrical Conductivity

The conductive materials used in twisted mounting shielding fingerstrips ensure that they provide high levels of EMI attenuation. This feature is essential for applications requiring reliable grounding and shielding.

3. Durable and Resilient Construction

These fingerstrips are engineered to withstand mechanical stress, environmental exposure, and repeated compression cycles, ensuring long-term performance.

4. Compact and Space-Saving Profile

Despite their robust performance, twisted mounting shielding fingerstrips occupy minimal space, making them suitable for applications where compactness is a priority.

5. Ease of Installation

The twisted design simplifies installation, reducing assembly time and ensuring secure placement on various surfaces.

Materials and Coatings

The performance of twisted mounting shielding fingerstrips depends heavily on the materials and coatings used.

Base Materials

- Beryllium Copper

- High electrical conductivity.

- Excellent spring properties for consistent contact pressure.

- Suitable for high-performance applications.

- Stainless Steel

- Superior strength and durability.

- High resistance to corrosion and wear.

- Ideal for harsh environments.

Plating Options

- Tin Plating

- Cost-effective.

- Provides good corrosion resistance.

- Suitable for applications in moderate environments.

- Nickel Plating

- Excellent resistance to oxidation and wear.

- Ideal for long-term applications in demanding environments.

- Silver Plating

- Best electrical conductivity among plating options.

- Used for high-frequency applications requiring minimal resistance.

- Gold Plating

- Exceptional corrosion resistance.

- Ideal for applications with high exposure to harsh chemicals or moisture.

Benefits of Twisted Mounting Shielding Fingerstrips

Twisted mounting shielding fingerstrips offer several advantages that make them a preferred choice in EMI shielding solutions.

1. Effective EMI Shielding

The high conductivity of the materials used ensures that these fingerstrips effectively block electromagnetic waves across a wide frequency spectrum.

2. Flexibility in Design and Application

The twisted design allows these fingerstrips to conform to complex geometries, ensuring consistent contact even on uneven or irregular surfaces.

3. Environmental Resistance

With their robust construction and protective coatings, twisted mounting shielding fingerstrips resist corrosion, oxidation, and environmental wear, making them suitable for outdoor or industrial applications.

4. Long-Term Durability

These components are built to endure repeated compression and mechanical stress without losing their effectiveness, ensuring reliable performance over time.

5. Ease of Integration

The simple installation process and compatibility with a variety of enclosure designs reduce assembly time and costs, making them a practical choice for manufacturers.

6. Cost-Effective Solution

The durability and reliability of twisted mounting shielding fingerstrips minimize the need for frequent replacements, offering a long-term cost advantage.

Applications

The versatility of twisted mounting shielding fingerstrips makes them suitable for a wide range of industries and applications.

1. Telecommunications

In the telecommunications sector, shielding fingerstrips are used to protect sensitive equipment, such as antennas, routers, and base stations, from EMI. Their high conductivity ensures uninterrupted signal transmission and reception.

2. Consumer Electronics

Twisted mounting shielding fingerstrips are used in devices such as smartphones, tablets, laptops, and wearable technology to ensure consistent performance in environments with high levels of electromagnetic noise.

3. Automotive Electronics

Modern vehicles rely on numerous electronic systems, including sensors, infotainment systems, and control units. Twisted mounting shielding fingerstrips provide reliable EMI protection, ensuring these systems function correctly in the presence of electromagnetic noise generated by the vehicle itself or its surroundings.

4. Aerospace and Defense

The aerospace and defense industries require robust and reliable shielding solutions. Twisted mounting shielding fingerstrips are ideal for use in avionics, radar systems, and military communications equipment due to their durability and high shielding performance.

5. Medical Devices

In medical applications, ensuring the proper functioning of devices such as imaging equipment, monitors, and pacemakers is critical. Twisted mounting shielding fingerstrips prevent EMI from compromising the accuracy and reliability of these devices.

6. Industrial Equipment

In industrial environments, machinery and control systems are often exposed to high levels of electromagnetic noise. Twisted mounting shielding fingerstrips provide effective shielding and grounding for these systems, ensuring reliable operation.

Installation Guidelines

Step 1: Surface Preparation

Ensure that the mounting surface is clean, dry, and free from debris. This step is crucial for achieving optimal contact and performance.

Step 2: Positioning the Fingerstrip

Align the shielding fingerstrip along the desired seam, edge, or opening. The twisted design allows it to conform to irregular surfaces.

Step 3: Securing the Fingerstrip

Press the fingerstrip into place, ensuring uniform compression along its length. For additional stability, adhesive-backed options or mounting clips can be used.

Step 4: Testing and Verification

After installation, test the assembly for continuity and shielding effectiveness to ensure proper performance.

Innovations and Future Trends

The design and functionality of twisted mounting shielding fingerstrips continue to evolve as industries demand higher performance and versatility. Some emerging trends include:

- Miniaturization: Development of smaller, more compact designs to accommodate increasingly compact electronic devices.

- Enhanced Plating Technologies: Innovations in plating materials and processes to improve conductivity and corrosion resistance.

- Hybrid Materials: Combining multiple materials to achieve an optimal balance of conductivity, flexibility, and durability.

- Smart Shielding: Integration of sensors and monitoring capabilities into shielding solutions for real-time performance assessment.

Conclusion

Twisted mounting shielding fingerstrips are a critical component in modern EMI shielding, offering unparalleled flexibility, durability, and performance. Their unique twisted design allows them to adapt to complex surfaces while maintaining consistent contact and shielding effectiveness.

By leveraging high-quality materials, advanced plating options, and robust construction, these fingerstrips provide reliable EMI protection across a variety of industries, from telecommunications and consumer electronics to aerospace and medical devices.

As technology advances, twisted mounting shielding fingerstrips are poised to play an even greater role in ensuring the reliability and performance of electronic systems. Their cost-effectiveness, ease of installation, and long-term durability make them a valuable investment for manufacturers and engineers alike.

You May Also Like

-

Handa Ultra Quick-Shield tin-plated stainless steel shielding gasket

Handa Ultra Quick-Shield tin-plated stainless steel shielding gasketEMI/EMC Shielding | RFI Shielding | EMI Gaskets

RF/EMI Shield Spiral Gasket

Handa Ultra Quick-Shield tin-plated stainless steel shielding gasket Introduction to EMI Shielding and Its ImportanceWhat Is the Handa Ultra Quick-Shield?Key Features of the Handa Ultra Quick-ShieldBenefits of Tin-Plated Stainless Steel Shielding Gaskets1. Enhanced Shielding Performance2. Corrosion and Wear Resistance3. Resilience......

-

Electrical conducting canted coil springs in high-voltage switchgear applications

Electrical conducting canted coil springs in high-voltage switchgear applicationsHanda Canted Coil Springs

Electrical conducting springs

Electrical conducting canted coil springs Abstract1. Introduction2. Structural Characteristics of Electrical Conducting Canted Coil Springs2.1 Simplicity and Compact Design2.2 Multiple Contact Points for Enhanced Conductivity2.3 Deformation Adaptability3. Material Selection for Electrical Conducting Canted Coil Springs3.1 Common Materials Used in Spring......

-

Durable and Lightweight Electrically Conductive Foam for Superior EMI Protection

Durable and Lightweight Electrically Conductive Foam for Superior EMI ProtectionShielding Gasket Solutions and Materials

Electrically conductive foam

1. Characteristics of Electrically Conductive FoamLightweight StructureHigh Elasticity and FlexibilityExcellent Thermal and Acoustic InsulationChemical ResistanceEnergy Absorption and Shock Resistance2. Manufacturing Process of Electrically Conductive FoamMaterial SelectionConductive FillersFoaming Agent and ProcessMixing and RefiningMolding and FormingPost-Treatment and Curing3. Applications of Electrically Conductive......

-

Copper foil tape with high conductivity&malleability

Copper foil tape with high conductivity&malleabilityEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Copper foil tape

Copper foil tape 1. Introduction to Copper Foil Tape2. Properties of Copper Foil Tape3. Types of Copper Foil Tape4. Applications of Copper Foil Tape4.1. Electromagnetic Interference (EMI) Shielding4.2. Grounding Applications4.3. Static Discharge Protection4.4. Printed Circuit Board (PCB) Applications4.5. Stained Glass......

-

Mu-Ferro Foil for Electromagnetic Interference (EMI) Shielding

Mu-Ferro Foil for Electromagnetic Interference (EMI) ShieldingEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Mu-ferro/mu-metal foil

1. What is Mu-Ferro Foil?2. Composition of Mu-Ferro Foil3. Magnetic Properties of Mu-Ferro Foil4. Applications of Mu-Ferro Foil4.1 Electromagnetic Interference (EMI) Shielding4.2 Magnetic Field Shielding4.3 Transformer and Inductor Design4.4 Aerospace and Defense Applications5. Advantages of Mu-Ferro Foil6. Challenges and Considerations7.......