Canted Coil Spring for EMI Shielding

Canted Coil Spring for EMI Shielding

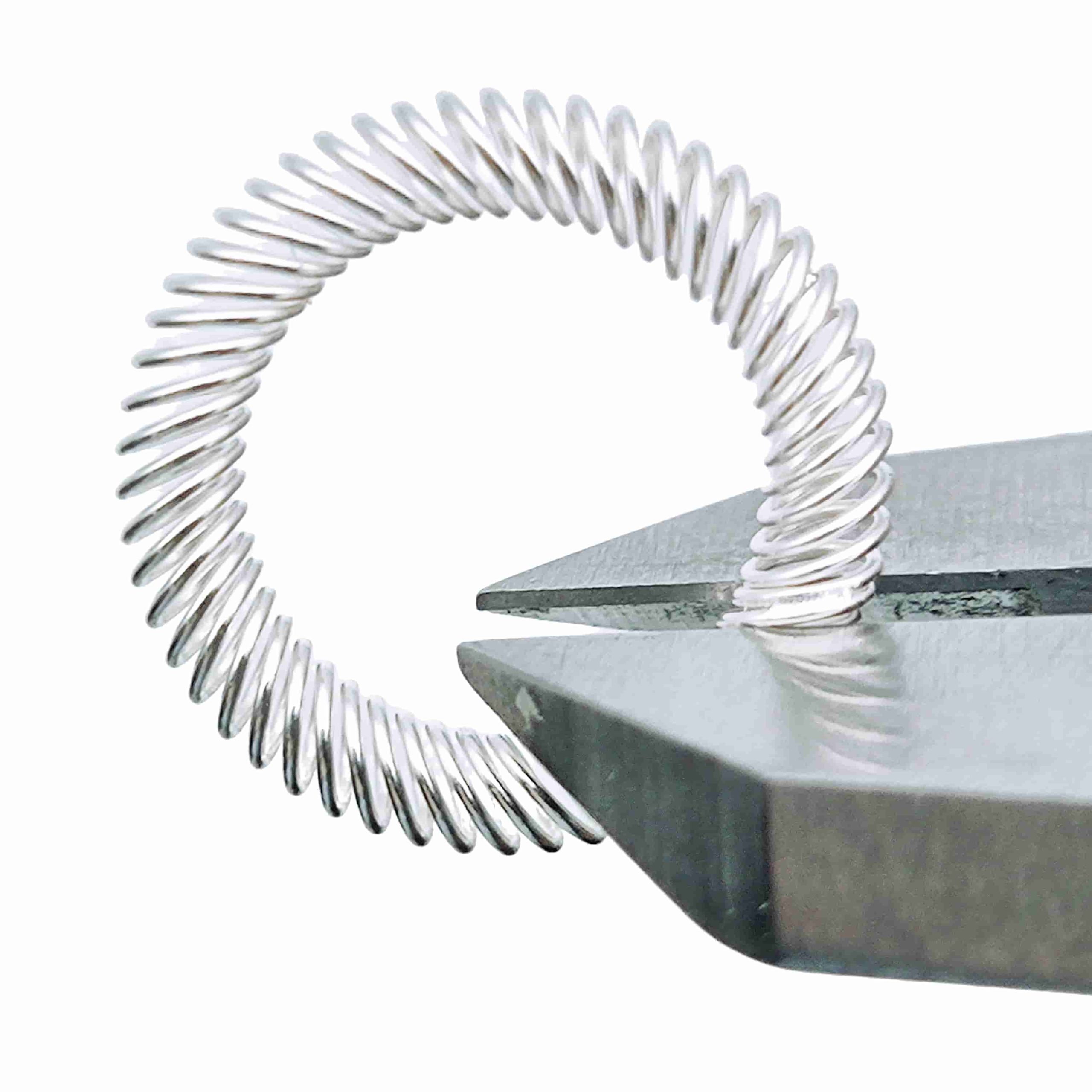

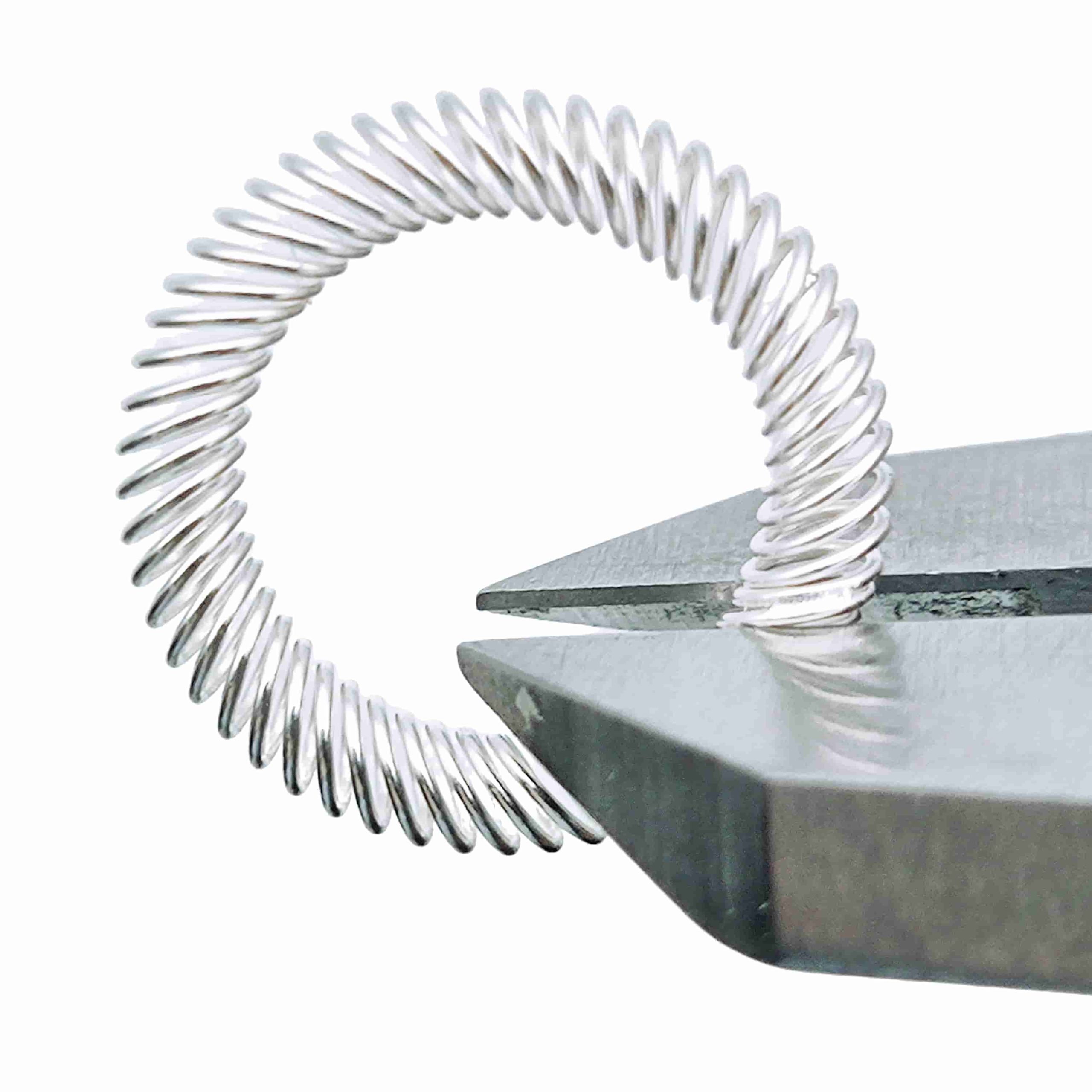

Die Canted Coil Spring for EMI Shielding is a high-performance conductive spring designed to provide reliable electromagnetic interference (EMI) shielding and electrical grounding in demanding electronic applications. Featuring a unique slanted coil geometry, this spring delivers a near-constant contact force over a wide deflection range, ensuring stable electrical conductivity even under vibration, thermal expansion, and repeated compression cycles.

Unlike traditional fingerstock or foam gaskets, canted coil springs maintain consistent performance throughout their service life. Their flat load-deflection curve minimizes insertion and breakout forces while compensating for dimensional tolerances, misalignment, and surface irregularities. This makes them ideal for applications requiring frequent engagement and disengagement, tight control of friction, or long-term reliability.

Manufactured from high-quality spring materials such as beryllium copper or stainless steel, and available with conductive plating options including tin, silver, or gold, these springs offer excellent corrosion resistance and shielding effectiveness in harsh environments. Custom sizes, wire diameters, and configurations are available to meet specific design and performance requirements.

Canted coil springs are widely used as EMI shielding gaskets, grounding elements, and conductive contacts in RF enclosures, telecommunications equipment, aerospace and defense electronics, medical devices, industrial control systems, and semiconductor manufacturing equipment.

Key Features & Benefits

-

Constant contact force over a wide compression range

-

Excellent electrical conductivity and EMI shielding performance

-

Long service life with millions of compression cycles

-

Low and stable mating force

-

Superior tolerance and misalignment compensation

-

Suitable for high-speed rotary and high-cycle applications

-

Custom sizes, materials, and plating available

Typische Anwendungen

-

EMI shielding for electronic enclosures

-

RF and microwave housings

-

Telecom and networking equipment

-

Aerospace and defense systems

-

Medical and diagnostic devices

-

Industrial and automation electronics

-

Semiconductor equipment

Available Options

-

Materials: Beryllium Copper, Stainless Steel, and custom alloys

-

Plating: Tin, Silver, Gold, or custom coatings

-

Configurations: Continuous rings or linear lengths

-

Custom dimensions upon request

Canted coil spring for EMI shielding provide consistent contact force, superior conductivity, and long service life. Learn how they work, key advantages over fingerstock, material options, installation design, and typical EMI shielding applications.

Canted Coil Spring for EMI Shielding

Electromagnetic interference (EMI) has become a critical challenge in modern electronic systems. As operating frequencies increase and devices become smaller, reliable EMI shielding solutions are essential to ensure signal integrity, regulatory compliance, and long-term product performance. Among various shielding technologies, the canted coil spring for EMI shielding stands out as a high-performance, durable, and design-flexible solution.

Unlike traditional fingerstock or foam-based gaskets, canted coil springs offer constant contact force, excellent electrical conductivity, and outstanding mechanical resilience, making them ideal for demanding environments and high-cycle applications.

This article provides a comprehensive overview of canted coil springs for EMI shielding, explaining how they work, their advantages, material options, installation considerations, and common applications.

What Is a Canted Coil Spring?

A Schrägzugfeder—also known as a slant coil spring, wire wound spring, or slanted coil spring—is a precision-engineered spring made by winding round or flat wire into coils that are intentionally angled (canted) rather than perpendicular to the spring axis.

This unique geometry allows the spring to compress with a flat load-deflection curve, meaning it delivers nearly constant force across a wide range of deflection. Unlike traditional compression springs that increase force rapidly as they compress, a canted coil spring maintains predictable and stable contact pressure.

Originally developed as an energizer for seals such as U-cups, canted coil springs are now widely used in EMI shielding applications, where consistent electrical contact is crucial.

How It Works in EMI Shielding

In EMI shielding, the primary goal is to create a continuous, low-resistance electrical path between mating surfaces—typically between an enclosure and a cover or between two conductive housings.

When used as an EMI shielding element, a canted coil spring:

- Is installed in a machined groove or channel

- Compresses when two conductive surfaces come together

- Maintains constant contact force even with tolerance variations

- Ensures reliable electrical grounding and shielding effectiveness

Because of its angled coil structure, the spring can absorb dimensional variations, thermal expansion, vibration, and repeated opening/closing cycles without losing contact force.

The result is stable EMI shielding performance across the product’s entire service life, even in harsh or high-cycle environments.

Advantages Over Fingerstock

Traditional EMI fingerstock gaskets are widely used, but they have inherent limitations. Canted coil springs offer several key advantages:

1. Constant Force Over Wide Deflection

Fingerstock typically exhibits increasing force with compression, which can cause assembly issues or excessive wear. Canted coil springs maintain nearly constant force, reducing stress on mating components.

2. Superior Durability and Cycle Life

Canted coil springs are designed for millions of compression cycles, making them ideal for applications requiring frequent engagement and disengagement, such as access panels or modular enclosures.

3. Improved Contact Reliability

The continuous spring geometry provides mehrere Kontaktstellen, ensuring consistent conductivity even if minor contamination or surface irregularities exist.

4. Better Tolerance Compensation

Canted coil springs easily accommodate misalignment, flatness variation, and thermal expansion, where fingerstock may permanently deform or lose effectiveness.

5. Lower and Controlled Mating Force

Because the force remains stable, designers can achieve effective EMI shielding while maintaining low insertion and breakout forces, especially important in handheld or serviceable equipment.

Typische Anwendungen

Canted coil springs for EMI shielding are used across a wide range of industries where reliability, performance, and longevity are critical:

- RF and microwave enclosures

- Telecom base stations and networking equipment

- Aerospace and defense electronics

- Medical diagnostic and imaging devices

- Industrial control cabinets

- Automotive electronics and EV systems

- Semiconductor manufacturing equipment

- Ruggedized outdoor or marine electronics

They are particularly suitable for high-speed rotary systems, sliding interfaces, and applications requiring tight control of friction and consistent grounding.

Material-Optionen

Material selection plays a crucial role in EMI shielding effectiveness, corrosion resistance, and mechanical life. Common material options include:

Beryllium-Kupfer (BeCu)

- Ausgezeichnete elektrische Leitfähigkeit

- Outstanding spring memory and fatigue resistance

- Ideal for high-performance EMI shielding

- Commonly plated for enhanced corrosion resistance

Rostfreier Stahl

- Good mechanical strength

- Suitable for harsh or corrosive environments

- Often used where conductivity requirements are moderate

Beschichtungsoptionen

To enhance performance, canted coil springs can be plated with:

- Tin (Sn) for improved conductivity and solderability

- Silver (Ag) for low contact resistance

- Gold (Au) for high-reliability, low-signal applications

Custom materials and plating combinations are available to meet specific environmental and electrical requirements.

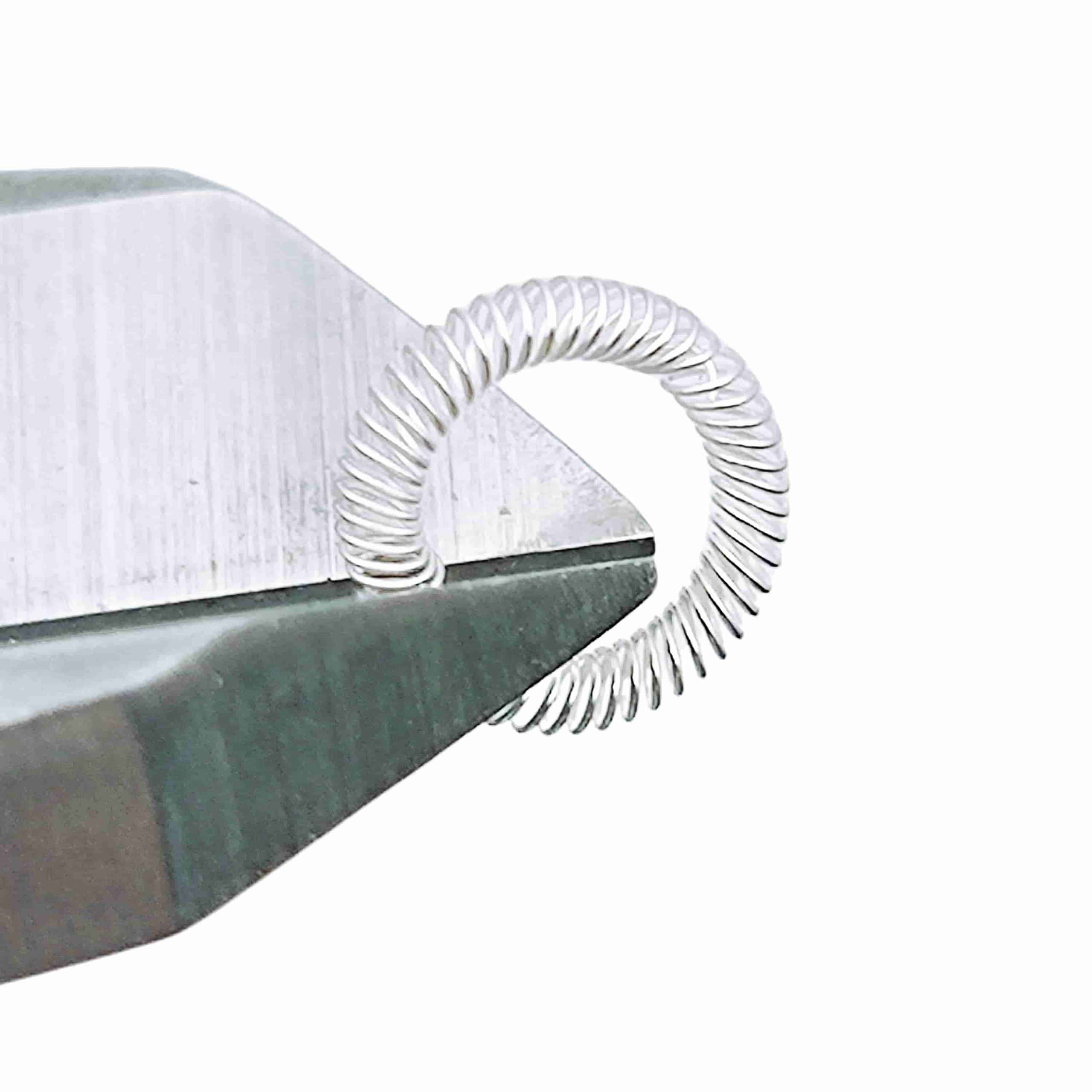

Installation & Groove Design

Proper installation and groove design are essential for optimal EMI shielding performance.

Groove Design Considerations

- Groove width and depth must allow sufficient compression

- Avoid sharp edges that could damage the spring

- Ensure conductive surfaces are clean and properly finished

Compression Recommendations

- Typical working compression ranges from 10% to 30%

- Over-compression can reduce cycle life

- Under-compression may lead to insufficient contact force

Installationsmethoden

Canted coil springs can be:

- Installed as continuous rings

- Supplied as linear lengths

- Customized to fit complex geometries

Their design flexibility allows easy integration into both new designs and retrofit applications.

Product Description

Canted Coil Spring for EMI Shielding

Our canted coil springs are precision-manufactured to provide reliable EMI shielding performance in demanding applications. Featuring a slanted coil geometry, these springs deliver constant contact force over a wide deflection range, ensuring stable electrical conductivity even under vibration, thermal cycling, and repeated use.

Available in custom sizes, materials, and plating options, they are ideal for use as EMI shielding gaskets, grounding elements, and conductive contacts in high-reliability electronic systems.

FAQs

Q1: What makes canted coil springs suitable for EMI shielding?

Their constant force, multiple contact points, and excellent conductivity make them ideal for maintaining reliable electrical grounding.

Q2: How do canted coil springs compare to fingerstock gaskets?

They offer longer service life, better tolerance compensation, and more consistent contact force.

Q3: Can canted coil springs be customized?

Yes. Custom diameters, wire sizes, materials, and plating options are available.

Q4: Are they suitable for high-cycle applications?

Absolutely. Canted coil springs are designed for millions of compression cycles.

Q5: What industries commonly use them?

Telecommunications, aerospace, medical devices, industrial electronics, automotive, and semiconductor equipment.

For more info.,please email to: sale01@handashielding.com

Das könnte Ihnen auch gefallen

-

HANDA RF/EMI Shielding Hastelloy Spiral Gasket for Semiconductor CVD Equipment

HANDA RF/EMI Shielding Hastelloy Spiral Gasket for Semiconductor CVD EquipmentRF/EMI-Abschirmung Spiralförmige Dichtung

Handa Spiralförmige Abschirmung

Discover HANDA’s RF/EMI Shielding Spiral Gasket made from premium Hastelloy C-276. Engineered for semiconductor CVD equipment, it delivers exceptional chemical resistance, high-temperature stability, and reliable RF/EMI attenuation for demanding plasma and vacuum process environments. HANDA proudly introduces its latest high-performance......

-

HANDA Spiral EMI Shielding Gaskets Solutions Now Available

HANDA Spiral EMI Shielding Gaskets Solutions Now AvailableRF/EMI-Abschirmung Spiralförmige Dichtung

Handa Spiralförmige Abschirmung

Hunan Handa Spiral Spring EMI Shielding Solutions New Partnership Announcement: HANDA Spiral EMI Shielding Gaskets Solutions Now Available.As the demand for reliable electromagnetic interference (EMI) protection continues to grow across electronics, telecommunications, automotive, and aerospace industries, manufacturers are seeking shielding......

-

High-Performance Conductive Fabric for EMI Shielding in Electronics and Communication Equipment

High-Performance Conductive Fabric for EMI Shielding in Electronics and Communication EquipmentEMI-Bänder, EMC-Folien, leitfähige Textilien und halbleitende Vliese

Conductive cloth/fabrics

1. Introduction to Conductive Fabric2. Key Performance Advantages3. Applications in Electronics and Communication3.1 Consumer and Industrial Electronics3.2 5G and Telecommunication Systems3.3 Automotive Electronics3.4 Aerospace and Defense3.5 Wearable and Medical Devices4. Technical Specifications5. Why Choose Handa Shielding7. Conclusion 1. Introduction to......

-

Electrical Conducting Springs: The Core Component for Efficient Connections in the Power Industry

Electrical Conducting Springs: The Core Component for Efficient Connections in the Power IndustryHanda Schrägspiralfedern

Elektrisch leitende Federn

In high-voltage switchgear, GIS (Gas-Insulated Switchgear), and power transmission and distribution systems, electrical conducting springs have emerged as indispensable key conductive components in modern power equipment, thanks to their unique structural design and superior electrical performance. Hunan Handa Electronics Technology......

-

Conductive Cloth Tape: Structure, Uses, Characteristics & Buying Guide

Conductive Cloth Tape: Structure, Uses, Characteristics & Buying GuideEMI-Bänder, EMC-Folien, leitfähige Textilien und halbleitende Vliese

Leitfähiges Gewebeband

Against the backdrop of the rapid development of modern electronic information technology, various electronic devices are emerging in an endless stream, and the electromagnetic environment is becoming increasingly complex. Electromagnetic interference not only affects the normal operation of equipment but......