HANDA Spiral EMI Shielding Gaskets Solutions Now Available

Spiral Spring EMI Shielding: A High-Performance Solution for Modern Electronic Devices

As electronic devices become smaller, faster, and more integrated, the need for effective electromagnetic interference (EMI) shielding continues to grow. Spiral spring EMI shielding has emerged as one of the most reliable and high-performance solutions for ensuring stable electrical contact, reducing EMI leakage, and maintaining device integrity in demanding applications.

This article explains what spiral spring EMI shielding is, how it works, and why it has become a preferred choice in advanced electronic systems.

What Is Spiral EMI Shielding?

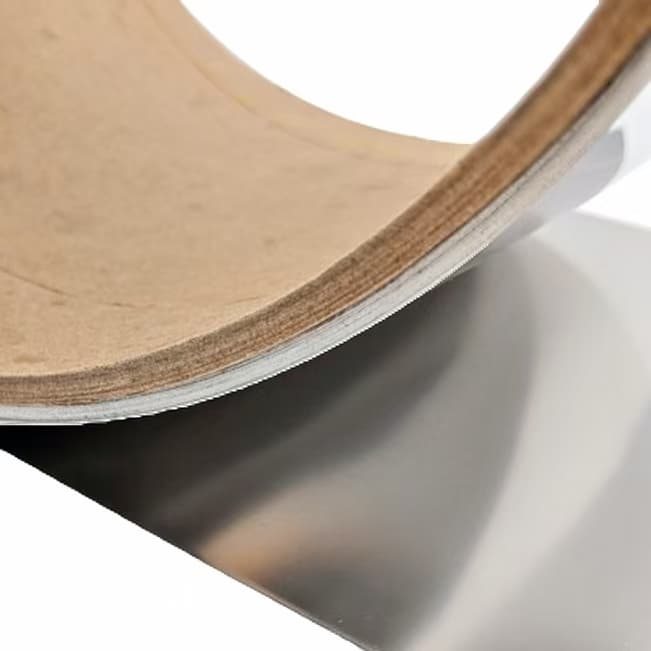

Spiral spring EMI shielding refers to the use of micro-precision spiral springs as conductive contact elements to block electromagnetic interference between device components or enclosure interfaces.

These conductive springs are typically made from:

-

Beryllium copper (BeCu)

-

Stainless steel (SUS301/304)

-

Phosphor Bronze

-

Nickel, tin, silver, or gold-plated materials

The spiral structure provides highly elastic compression, stable contact resistance, and excellent shielding effectiveness, making it suitable for RF modules, telecom equipment, and precision electronics.

How Spiral EMI Shielding Works

The spiral spring is installed between two conductive surfaces:

-

Device frame

-

Shielding cover / metal enclosure

-

PCB edge

-

Grounding point

When compressed, the spring creates multi-point electrical contact, forming a continuous conductive path that blocks EMI and ensures proper grounding.

Key performance advantages:

-

High-frequency EMI suppression

-

Low and stable contact resistance

-

Flexible compression range

-

Long operational life (thousands of cycles)

-

Excellent resilience and fatigue resistance

Benefits of Using Spiral EMI Shielding

✔ Superior Shielding Performance

The multi-contact spiral design provides a low-impedance path for noise reduction and minimizes RF leakage.

✔ Durable and Long-Lasting

The spring’s elastic structure maintains performance even under repeated compression cycles.

✔ Compact and Lightweight

Ideal for compact consumer electronics, wearable devices, and telecom modules.

✔ Customizable for Different Applications

Spiral springs can be customized in wire diameter, outer diameter, free height, plating, and mounting method.

✔ Zuverlässige Erdung

Ensures stable electrical grounding for sensitive components.

Common Applications of Spiral Spring EMI Shielding

Spiral spring EMI solutions are widely used in:

Telekommunikation

-

5G/6G base station modules

-

RF front-end components

-

Small-cell equipment

Unterhaltungselektronik

-

Smartphones

-

Tablets

-

Tragbare Geräte

Kfz-Elektronik

-

ADAS controllers

-

Radar and lidar modules

-

EV communication systems

Medizinische Geräte

-

Imaging equipment

-

Monitoring devices

Industrielle Kontrollsysteme

-

Control units

-

High-frequency sensors

-

Industrial computing hardware

Wherever compact structure and high-reliability EMI suppression are required, spiral spring shielding is an excellent fit.

Design Considerations for Spiral EMI Shielding

When selecting or designing a spiral spring EMI solution, engineers should evaluate:

-

Contact force requirements

-

Compression ratio

-

Shielding effectiveness (dB performance)

-

Material and plating compatibility

-

Mounting method (adhesive, slot, groove, etc.)

-

Environmental conditions (humidity, vibration, corrosion)

Proper selection ensures maximum performance and reliability in real-world usage.

Why Spiral Outperform Traditional EMI Gaskets

Compared with foam gaskets, conductive cloth gaskets, or finger stock, spiral springs offer:

| Merkmal | Spiral Spring | Traditional EMI Gasket |

|---|---|---|

| Contact stability | Ausgezeichnet | Mittel |

| Compression life | Very long | Shorter |

| High-frequency shielding | Strong | Mäßig |

| Heat resistance | Ausgezeichnet | Varies |

| Dimensional precision | Hoch | Mittel |

This makes spiral spring EMI shielding ideal for next-generation miniaturized electronic systems.

Schlussfolgerung

Spiral EMI shielding is a high-performance, reliable, and customizable solution for modern electronics requiring stable grounding and effective electromagnetic protection. With their precision structure and excellent mechanical properties, spiral springs provide superior durability and EMI suppression compared to traditional gasket materials.

Whether you’re designing telecom equipment, consumer electronics, or automotive systems, spiral spring EMI shielding offers the performance and precision needed for today’s high-density electronic environments.

Hunan Handa Spiral Spring EMI Shielding Solutions

New Partnership Announcement: HANDA Spiral EMI Shielding Gaskets Solutions Now Available.As the demand for reliable electromagnetic interference (EMI) protection continues to grow across electronics, telecommunications, automotive, and aerospace industries, manufacturers are seeking shielding components that deliver stability, durability, and consistent performance. We are excited to announce that Handa—a leading manufacturer specializing in precision spiral springs and customized EMI shielding solutions—is now officially available through our supply network.

With decades of engineering experience and advanced production capabilities, Handa provides high-precision EMI spiral gasket, shielding gaskets, and conductive components that meet the strict requirements of global OEMs.

About Handa

Hunan Handa is a professional manufacturer focused on micro-precision spiral gaskets, EMI shielding gaskets, and conductive metal parts. With strong R&D capability and automated production lines, Handa is known for:

- Ultra-precise spring dimensions and tight tolerances

- High-conductivity material selection

- Reliable compression, contact force, and long-cycle durability

- Customizable EMI shielding solutions for complex structures

The company serves markets such as 5G communication equipment, consumer electronics, medical devices, automotive electronics, and industrial control systems.

Leading EMI Shielding Solutions from Handa

1. Spiral Spring EMI Shielding Gaskets

Handa’s spiral spring gaskets provide consistent contact force, excellent conductivityund high-frequency shielding for edge and frame interfaces. They are commonly used in:

- RF modules

- Shielding cans

- Communication devices

- Precision electronic enclosures

The unique spiral design ensures stable compression, low insertion forceund long service life, making it ideal for high-reliability applications.

2. Custom Spiral Springs & Wire-Formed Components

Handa offers tailored spring designs based on customer requirements:

- Wire diameter from microns to millimeters

- Multiple materials (beryllium copper, stainless steel, phosphor bronze, etc.)

- Nickel, silver, and gold plating options

- Various mounting structures

This flexibility allows Handa’s EMI shielding gasket to support complex EMI structures and special mechanical constraints.

3. High-Performance Conductive Solutions

To meet advanced EMI requirements, Hunan Handa also provides:

- Conductive pads

- Shielding clips

- Compression springs for grounding

- Multi-point contact springs for frame sealing

These components ensure stable grounding, minimize RF leakage, and improve overall device reliability.

Why Choose EMI Solutions from Hunan Handa?

✔ Precision Manufacturing

Advanced CNC equipment, laser inspection systems, and strict process controls guarantee high-consistency parts.

✔ Superior Shielding Performance

High-conductivity materials and optimized structural design deliver effective EMI suppression across wide frequency ranges.

✔ Long-Life Mechanical Durability

Handa’s spiral springs maintain elasticity and contact stability even after thousands of compression cycles.

✔ Fast Customization for OEM Projects

Rapid prototyping and flexible engineering support enable fast design validation and optimized cost performance.

✔ Global-Standard Compliance

Products meet RoHS, REACH, and international quality standards for electronics and telecom industries.

Industries Served

Hunan Handa’s shielding and spring components are widely used in:

- 5G/6G communication equipment

- Mobile devices and wearables

- Automotive electronics & ADAS

- Medical instruments

- Industrial control units

- Aerospace electronics

Wherever high-reliability EMI protection is required, Handa delivers dependable solutions.

Partner With Us for Hunan Handa EMI Shielding Components

We are proud to bring Hunan Handa’s premium spiral spring and EMI shielding products directly to global customers. Whether you need standard springs or fully customized shielding designs, our team provides:

- Technical consultation

- Engineering optimization

- Rapid sampling

- Stable supply and logistics

Contact us today to discuss your EMI challenges and discover how Hunan Handa’s solutions can support your next-generation product development.

Das könnte Ihnen auch gefallen

-

High-Performance Conductive Fabric for EMI Shielding in Electronics and Communication Equipment

High-Performance Conductive Fabric for EMI Shielding in Electronics and Communication EquipmentEMI-Bänder, EMC-Folien, leitfähige Textilien und halbleitende Vliese

Conductive cloth/fabrics

1. Introduction to Conductive Fabric2. Key Performance Advantages3. Applications in Electronics and Communication3.1 Consumer and Industrial Electronics3.2 5G and Telecommunication Systems3.3 Automotive Electronics3.4 Aerospace and Defense3.5 Wearable and Medical Devices4. Technical Specifications5. Why Choose Handa Shielding7. Conclusion 1. Introduction to......

-

Electrical Conducting Springs: The Core Component for Efficient Connections in the Power Industry

Electrical Conducting Springs: The Core Component for Efficient Connections in the Power IndustryHanda Schrägspiralfedern

Elektrisch leitende Federn

In high-voltage switchgear, GIS (Gas-Insulated Switchgear), and power transmission and distribution systems, electrical conducting springs have emerged as indispensable key conductive components in modern power equipment, thanks to their unique structural design and superior electrical performance. Hunan Handa Electronics Technology......

-

Conductive Cloth Tape: Structure, Uses, Characteristics & Buying Guide

Conductive Cloth Tape: Structure, Uses, Characteristics & Buying GuideEMI-Bänder, EMC-Folien, leitfähige Textilien und halbleitende Vliese

Leitfähiges Gewebeband

Against the backdrop of the rapid development of modern electronic information technology, various electronic devices are emerging in an endless stream, and the electromagnetic environment is becoming increasingly complex. Electromagnetic interference not only affects the normal operation of equipment but......

-

Mu-Metall-Folie mit hervorragenden magnetischen Eigenschaften

Mu-Metall-Folie mit hervorragenden magnetischen EigenschaftenEMI-Bänder, EMC-Folien, leitfähige Textilien und halbleitende Vliese

Mu-Ferro/Mu-Metall-Folie

Abstract: This article delves into the production process of mu-metal foil, covering the entire workflow from raw material selection to finished product output. In the raw material preparation stage, strict control is imposed on high-purity iron, nickel, and other raw......

-

Das neue Produkt von Handa: Glasfaser-Aluminium-Folien-Band

Das neue Produkt von Handa: Glasfaser-Aluminium-Folien-BandEMI-Bänder, EMC-Folien, leitfähige Textilien und halbleitende Vliese

Glasfaser-Aluminium-Folien-Band

🔧 Produktübersicht📌 Hauptmerkmale & Benefits⚙️ Technische Daten🎯 Anwendungen🛠 Anpassungsmöglichkeiten📦 Verpackung & Lieferung🧩 Warum Handa wählen?📞 Angebot oder Muster anfordern Das Glasfaser-Aluminiumfolienband von Handa ist eine hochleistungsfähige Isolier- und Dichtungslösung, die für anspruchsvolle industrielle, ......