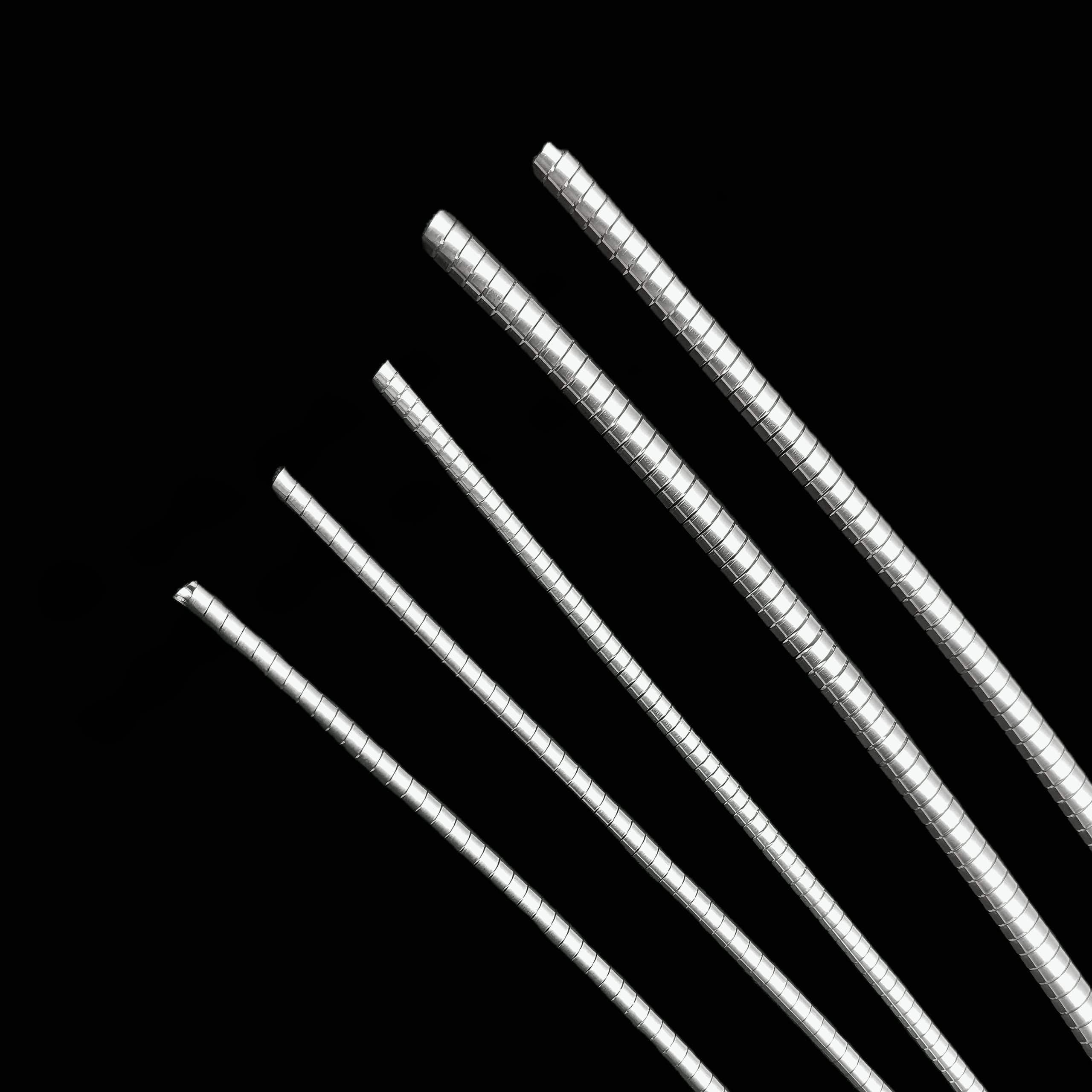

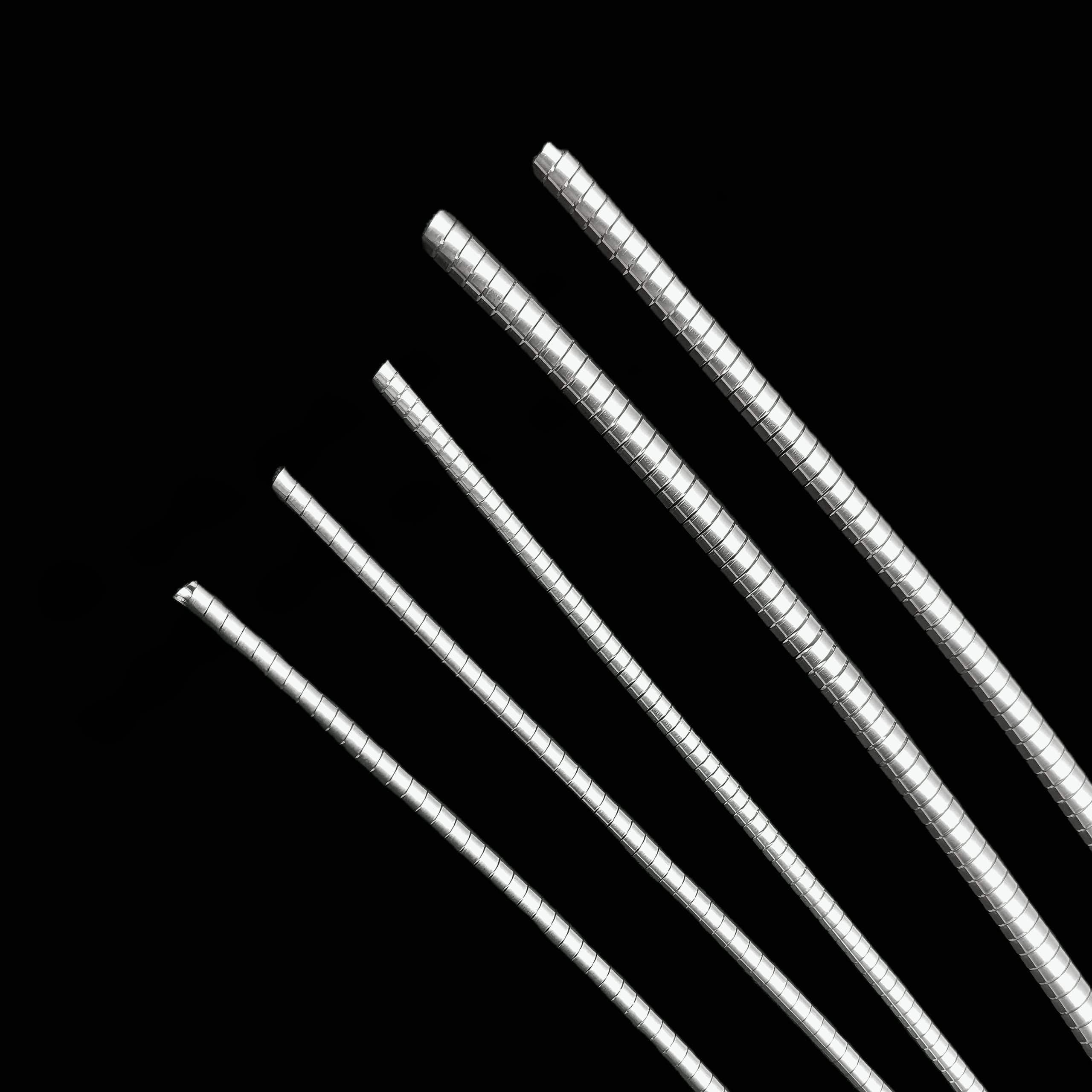

RF/EMI Shield Spiral Gaskets: Essential Components for Electromagnetic Compatibility

RF/EMI Shield Spiral Gaskets are specialized components designed to provide robust shielding against electromagnetic radiation. They are typically made from conductive materials such as metal alloys or conductive elastomers, crafted into a spiral shape that allows them to conform closely to mating surfaces. This design ensures consistent contact and compression, optimizing the gasket’s ability to block EMI effectively.

In today’s interconnected world of electronics and telecommunications, maintaining electromagnetic compatibility (EMC) is crucial to ensure optimal performance and reliability of electronic devices. RF/EMI Shield Spiral Gaskets play a pivotal role in achieving this goal by effectively mitigating electromagnetic interference (EMI) that can disrupt signal integrity and functionality.

Table of Contents

What are RF/EMI Shield Spiral Gaskets?

RF/EMI Shield Spiral Gaskets are specialized components designed to provide robust shielding against electromagnetic radiation. They are typically made from conductive materials such as metal alloys or conductive elastomers, crafted into a spiral shape that allows them to conform closely to mating surfaces. This design ensures consistent contact and compression, optimizing the gasket’s ability to block EMI effectively.

Key Features and Benefits

- EMI Shielding Effectiveness: The primary function of RF/EMI Shield Spiral Gaskets is to attenuate electromagnetic waves, preventing external interference from disrupting sensitive electronic signals. This capability is crucial for maintaining signal integrity and preventing data corruption in telecommunications, aerospace, medical devices, and industrial automation.

- Versatility in Applications: These gaskets are available in various sizes, shapes, and materials to suit different application requirements. They are commonly used in:

Telecommunications: Ensuring clear and reliable communication by shielding equipment from EMI generated by nearby devices or environmental factors.

Aerospace: Protecting avionics and onboard electronics from external electromagnetic fields that could interfere with navigation and communication systems.

Medical Devices: Maintaining the accuracy and reliability of medical equipment such as MRI machines and patient monitoring systems by preventing EMI-induced malfunctions.

Industrial Automation: Shielding control systems and sensitive electronics in manufacturing environments to prevent EMI-related disruptions and equipment failures. - Material Durability and Reliability: RF/EMI Shield Spiral Gaskets are engineered from materials that offer high durability and resilience to environmental factors such as temperature variations, moisture, and mechanical stress. This ensures long-term performance and reliability, reducing maintenance costs and downtime.

- Ease of Installation: Designed for ease of assembly, these gaskets feature flexible and conformable properties that facilitate quick and efficient installation. They conform closely to irregular surfaces, ensuring a tight seal that maximizes shielding effectiveness without complex installation procedures.

Applications Across Industries

The versatility and effectiveness of RF/EMI Shield Spiral Gaskets make them indispensable in various industries where EMC is critical:

- Telecommunications: In cellular base stations, antennas, and satellite communication systems to maintain signal clarity and reliability.

- Aerospace and Defense: Essential for shielding electronic systems in aircraft, spacecraft, radar systems, and military communication equipment to ensure operational safety and efficiency.

- Medical Technology: Used in medical imaging devices (MRI, CT scanners), patient monitoring systems, and implantable medical devices to prevent EMI that could compromise patient safety and device performance.

- Industrial Automation: Critical for shielding PLCs (Programmable Logic Controllers), electronic sensors, and control systems in manufacturing environments to minimize EMI-related disturbances and ensure continuous production processes.

In conclusion, RF/EMI Shield Spiral Gaskets are integral components that uphold electromagnetic compatibility standards in modern electronic applications. Their ability to mitigate EMI effectively ensures the seamless operation of electronic devices across diverse sectors. For organizations seeking reliable EMC solutions, investing in high-quality RF/EMI Shield Spiral Gaskets is a strategic choice to safeguard performance and longevity.

For further information on how RF/EMI Shield Spiral Gaskets can benefit your specific application needs, contact our expert team today.

You May Also Like

-

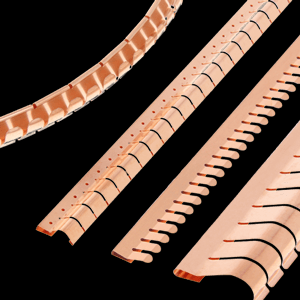

Handa Shielding – Clip-on mounting fingerstrip

Handa Shielding – Clip-on mounting fingerstripFingerstrips

Clip-on mounting shielding fingerstrip

Clip-on mounting fingerstrip gaskets are essential components in the realm of electromagnetic shielding, playing a critical role in ensuring the effective performance of electronic devices and systems. These gaskets, produced by leading manufacturers like Handa Shielding, are designed to provide......

-

Electrical Conducting Canted Coil Springs

Electrical Conducting Canted Coil SpringsHanda Canted Coil Springs

Electrical conducting springs

Electrical Conducting Springs In the fields of electrical and mechanical engineering, electrical conducting canted coil springs have emerged as pivotal components due to their unique blend of electrical conductivity and mechanical robustness. This article provides an in-depth examination of canted......

-

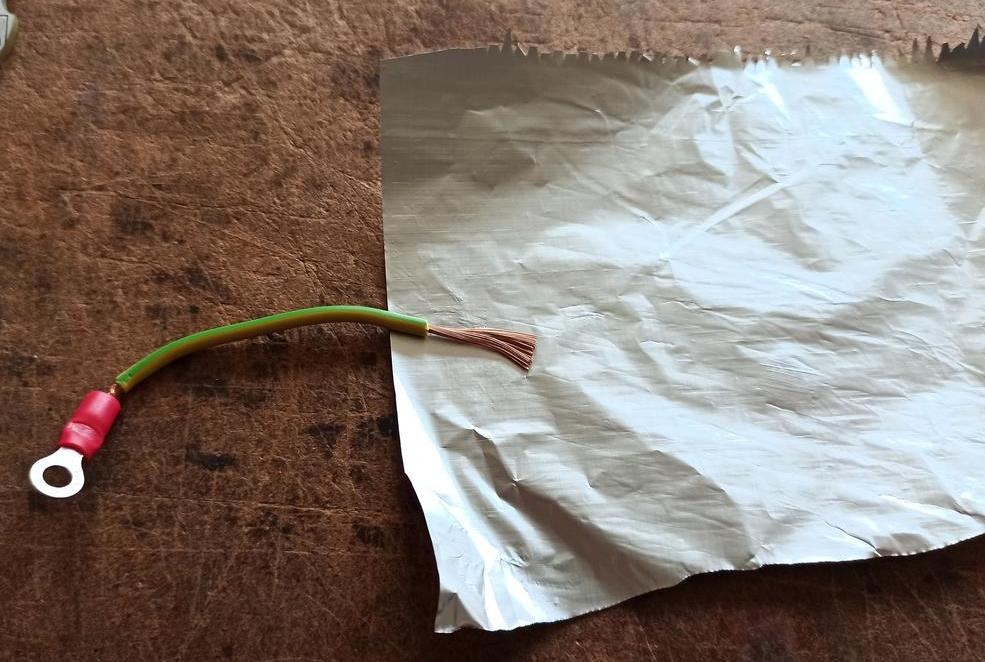

Aluminium Foil in Electromagnetic Shielding

Aluminium Foil in Electromagnetic ShieldingEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Conductive aluminium tape

Aluminium foil, a widely recognized material in both household and industrial applications, is particularly valued for its role in electromagnetic shielding. This article delves into the properties, applications, and considerations surrounding the use of aluminium foil for electromagnetic shielding. Its......

-

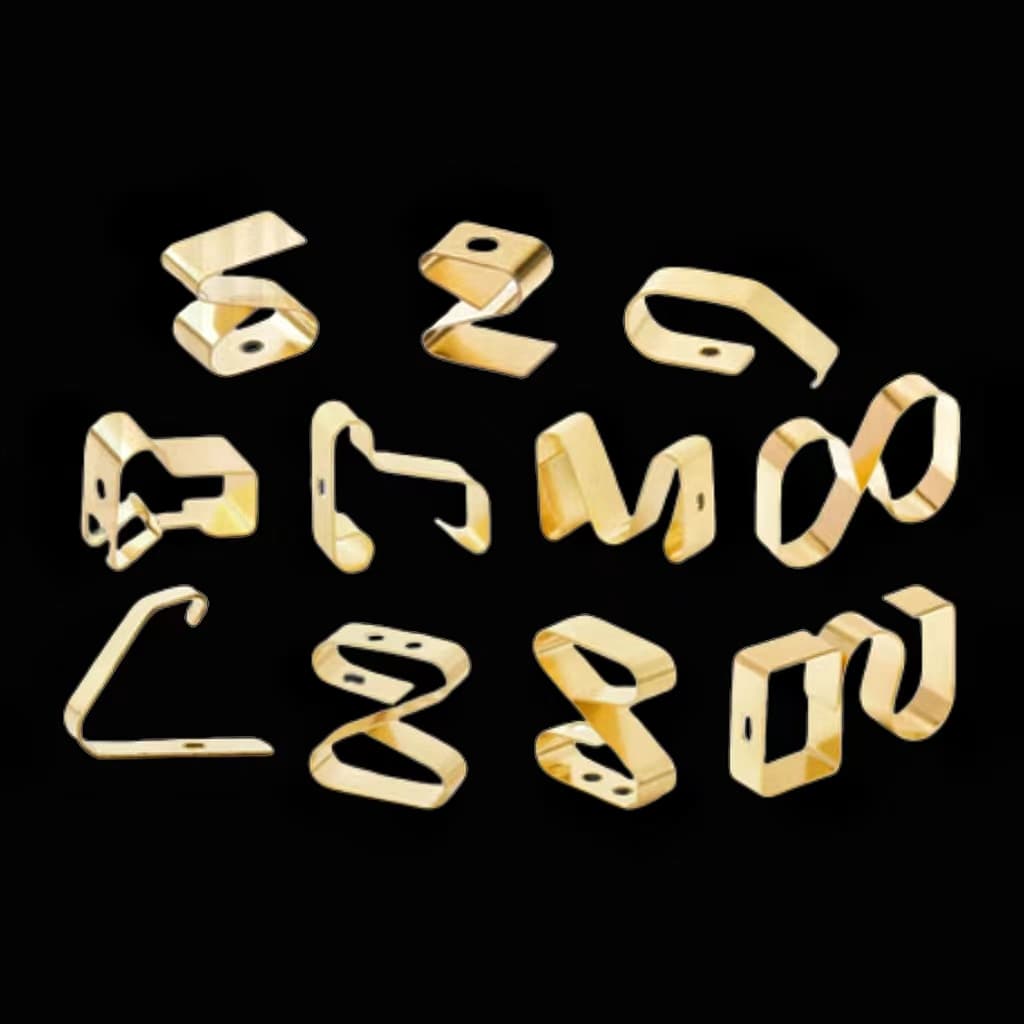

Electrical Contact Finger Springs

Electrical Contact Finger SpringsEMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

Introduction to Contact Finger Springs Contact finger springs are crucial components in the field of electronics and electrical engineering. They play a pivotal role in ensuring reliable electrical connections in a wide array of devices and systems. Understanding these components......

-

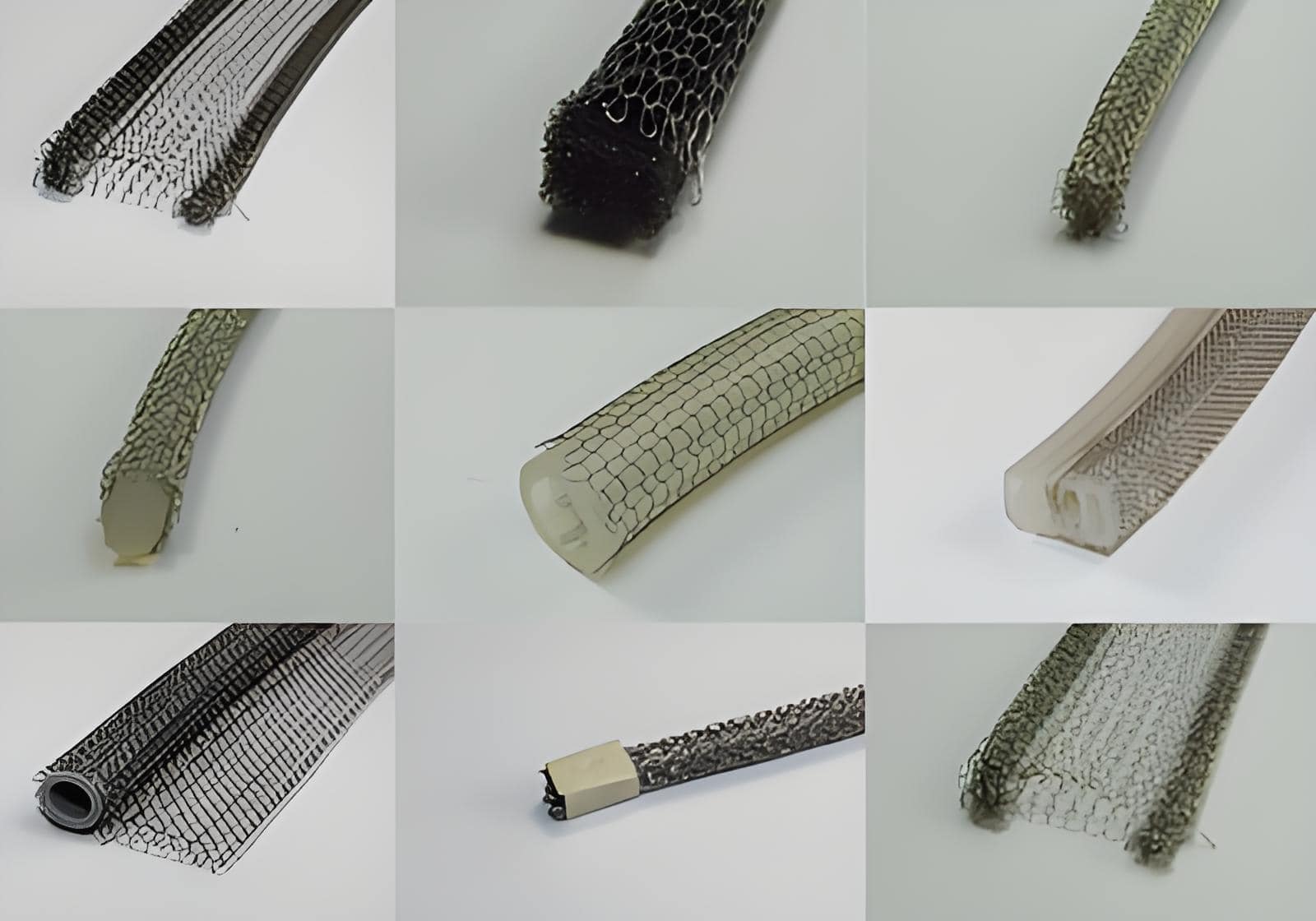

Knitted Metal Wire Mesh Gaskets:a highly versatile method of shielding

Knitted Metal Wire Mesh Gaskets:a highly versatile method of shieldingShielding Gasket Solutions and Materials

Knitted wire mesh gaskets

Knitted metal wire mesh gaskets are engineered using fine metal wires, typically stainless steel or other conductive alloys, that are knitted or woven into a mesh structure. This design enables the gaskets to conform closely to mating surfaces, providing a......