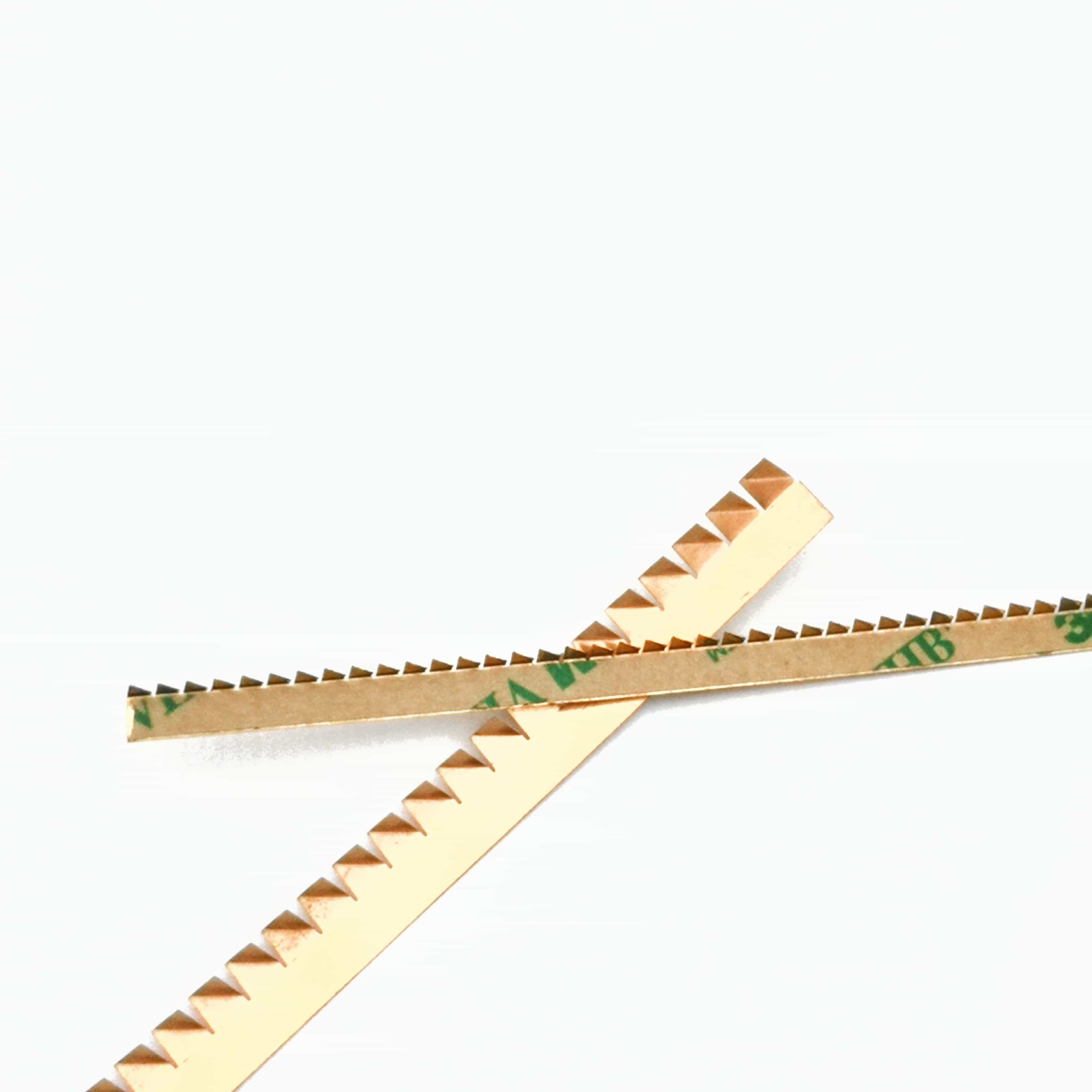

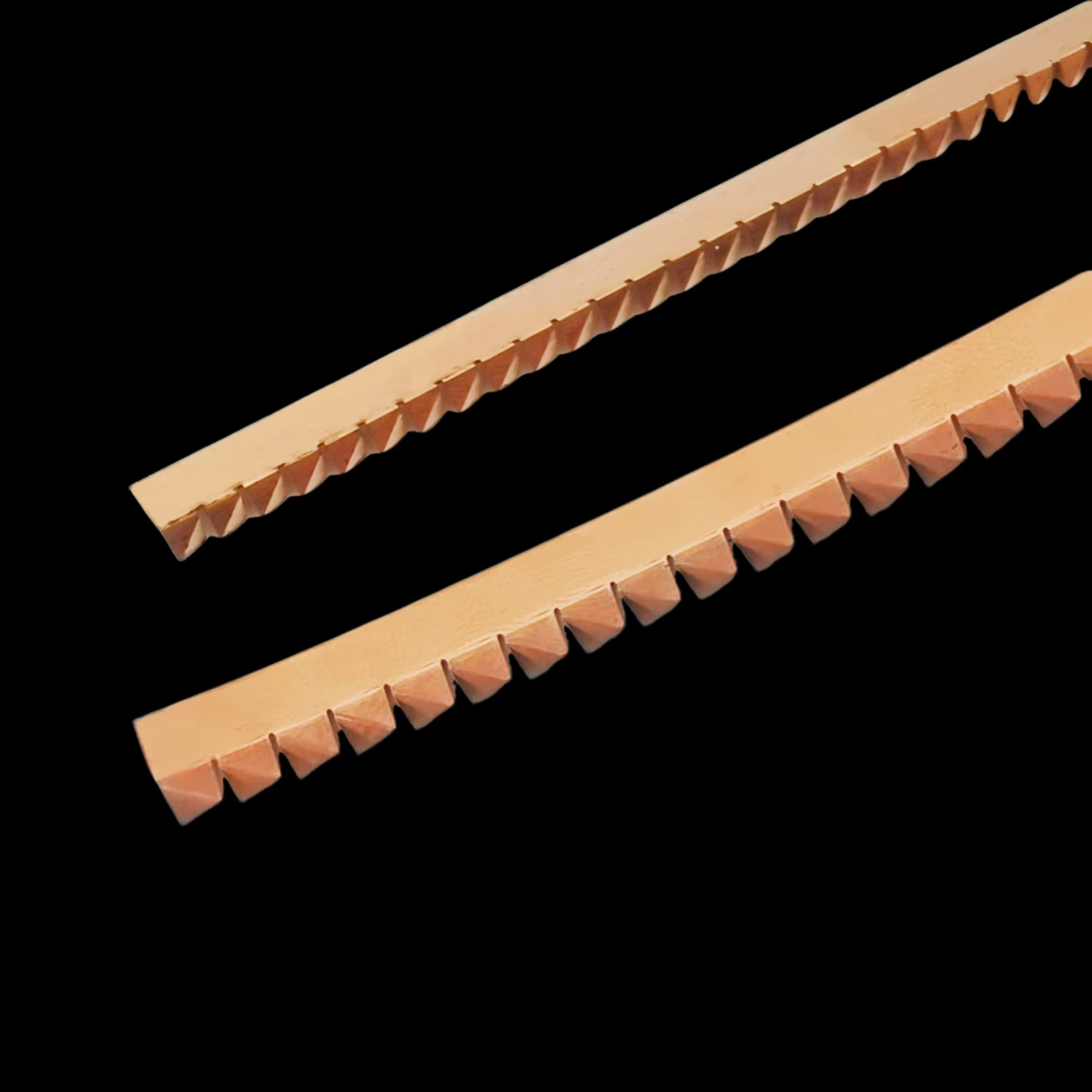

Twisted mounting shielding fingerstrip

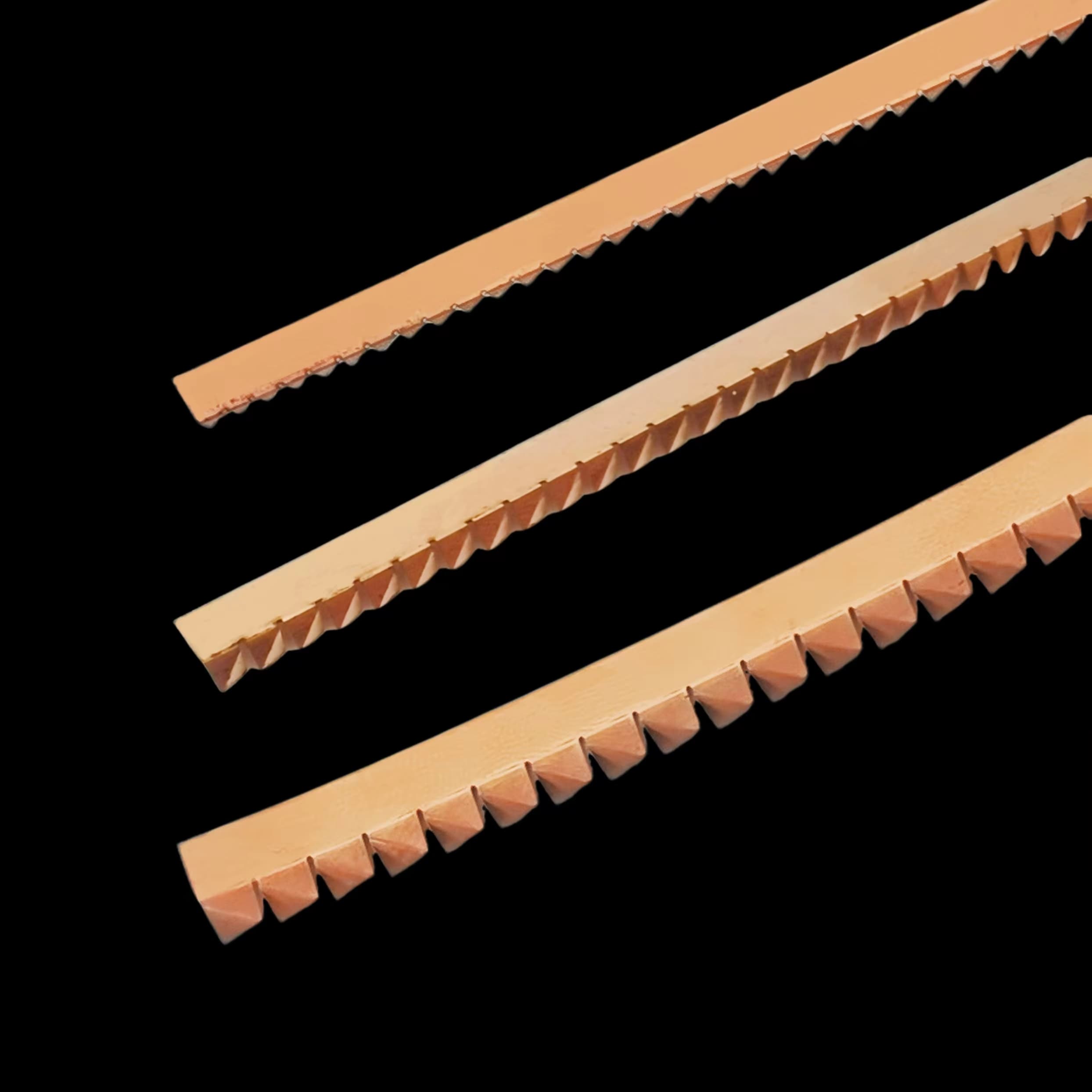

Handa twisted mounting shielding fingerstrip has excellent compression resistance, resilience and corrosion resistance. It provides good broadband electromagnetic shielding effect especially suitable for the gap filling of communication cabinets and computers, cabinet/room doors of shielding rooms, panels etc.

Product Specs

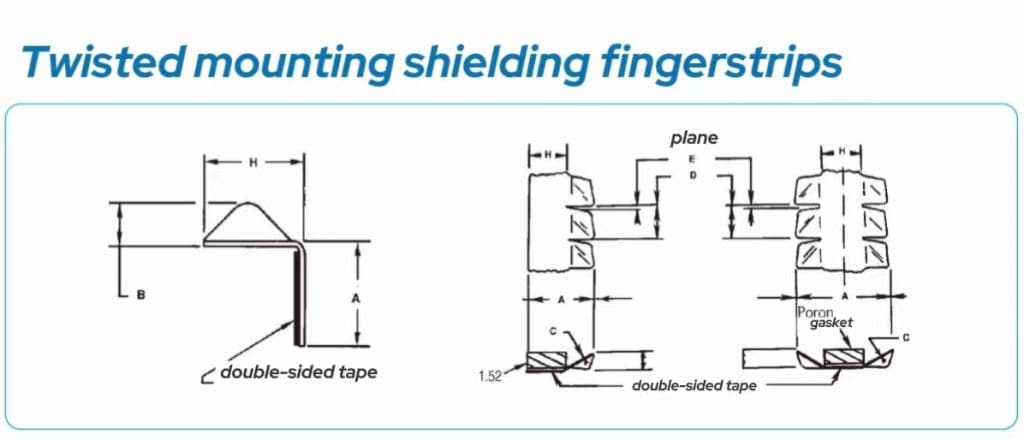

Size specification

Handa twisted mounting shielding fingerstrips dimensions vary by manufacturer and product model. The following are some possible dimensional specifications, but please note that specific specifications should be confirmed with Handa shielding to meet the requirements of the specific application:

| No. | A | B | C | D | E | H | length(mm) | roll length(mm) | gasket |

|---|---|---|---|---|---|---|---|---|---|

| 97-5500 | 5.84 | 0.76 | 0.08 | 2.41 | 0.38 | 3.56 | 609.60 | 7.6 | / |

| 97-5510 | 4.06 | 0.76 | 0.08 | 2.41 | 0.38 | 2.03 | 609.60 | – | / |

| 97-5550 | 8.64 | 1.78 | 0.08 | 4.19 | 0.38 | 4.57 | 609.60 | 7.6 | / |

| 97-5580 | 5.08 | 1.78 | 0.08 | 4.19 | 0.38 | 2.79 | 609.60 | – | / |

| 97-5600 | 12.70 | 1.78 | 0.08 | 4.19 | 0.38 | 4.83 | 609.60 | 7.6 | / |

Custom Manufacturing

Custom Twisted mounting shielding fingerstrip

According to the customer’s requirements, Handa Shielding provide drawings or dimensions and working conditions requirements for product customization. If necessary, please contact sunny@handashielding.com and a professional engineer will answer your questions. Thank you!

Twisted mounting shielding fingerstrip Manufacturing

Manufacturing twisted fingerstrips involves several steps, focusing on creating a product that effectively shields against electromagnetic interference (EMI) while maintaining flexibility and ease of installation:

1. Material Selection:Beryllium-Copper Alloy,It’s ideal for applications requiring high EMI shielding effectiveness.

2. Wire Preparation:Choose wires with the appropriate diameter and length according to the design specifications.

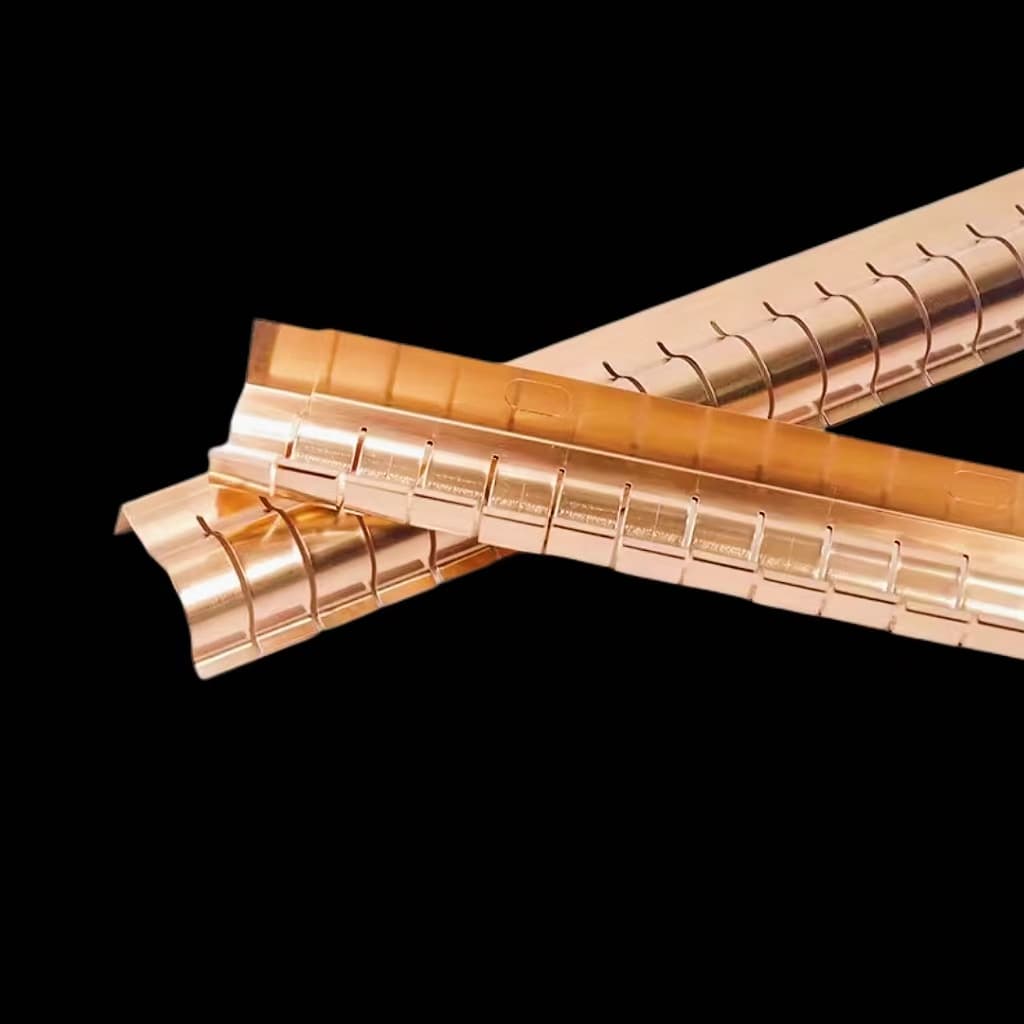

3. Forming the Coil:Wind the wire around a mandrel or former to form the initial coil shape.

4. Heat Treatment: Optionally, heat treat the coiled wire to increase its hardness and wear resistance, enhancing the spring’s longevity and performance.

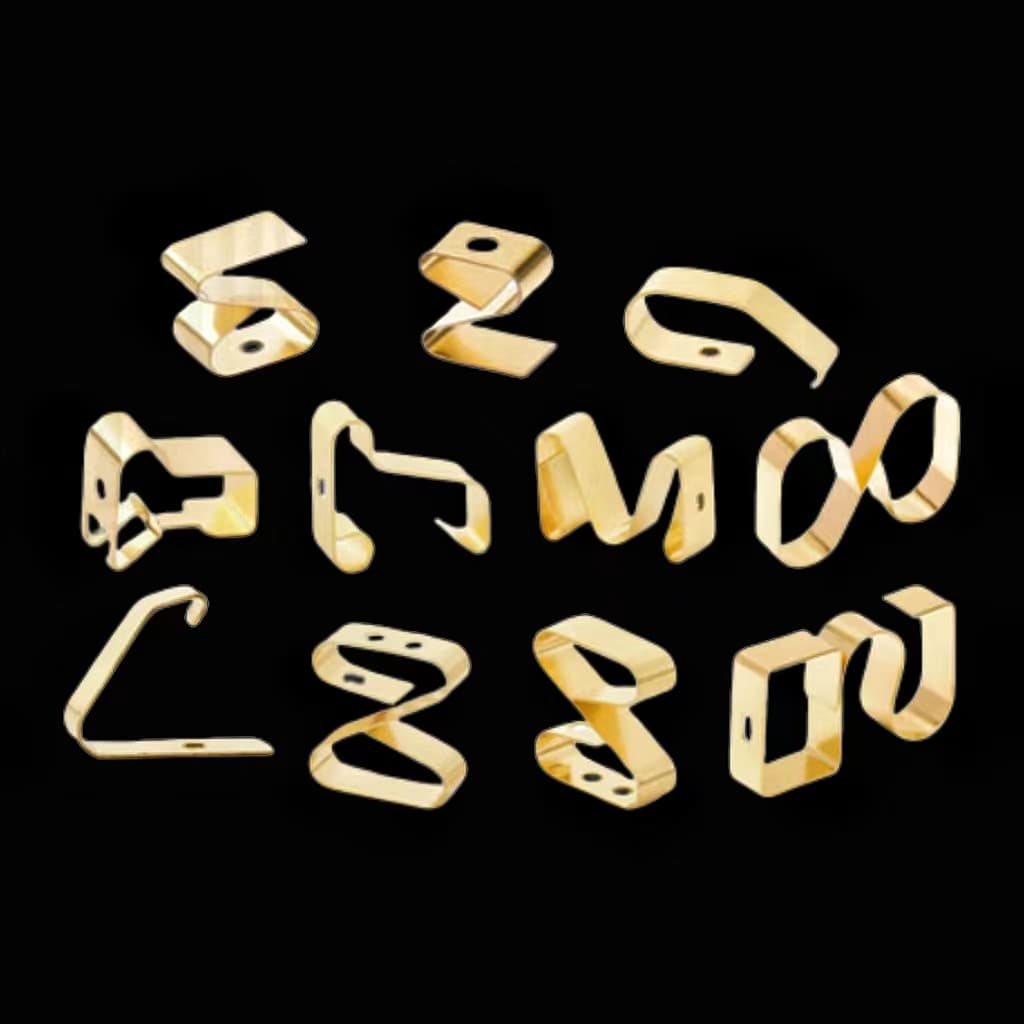

5. Cutting and Shaping

(1) Cutting to Length: Cut the coiled wire to the required length.

(2) Shaping: Twist the ends of the wire to create the characteristic twisted configuration of fingerstrips.

6. Finishing

(1) Surface Treatment: Apply surface treatments like plating or coating if necessary.

(2) Packaging: Package the finished twisted fingerstrips securely.

7. Quality Assurance

Testing: Involve measuring the spring constant, conducting bend tests, and evaluating the shielding effectiveness at various frequencies.

Benefits

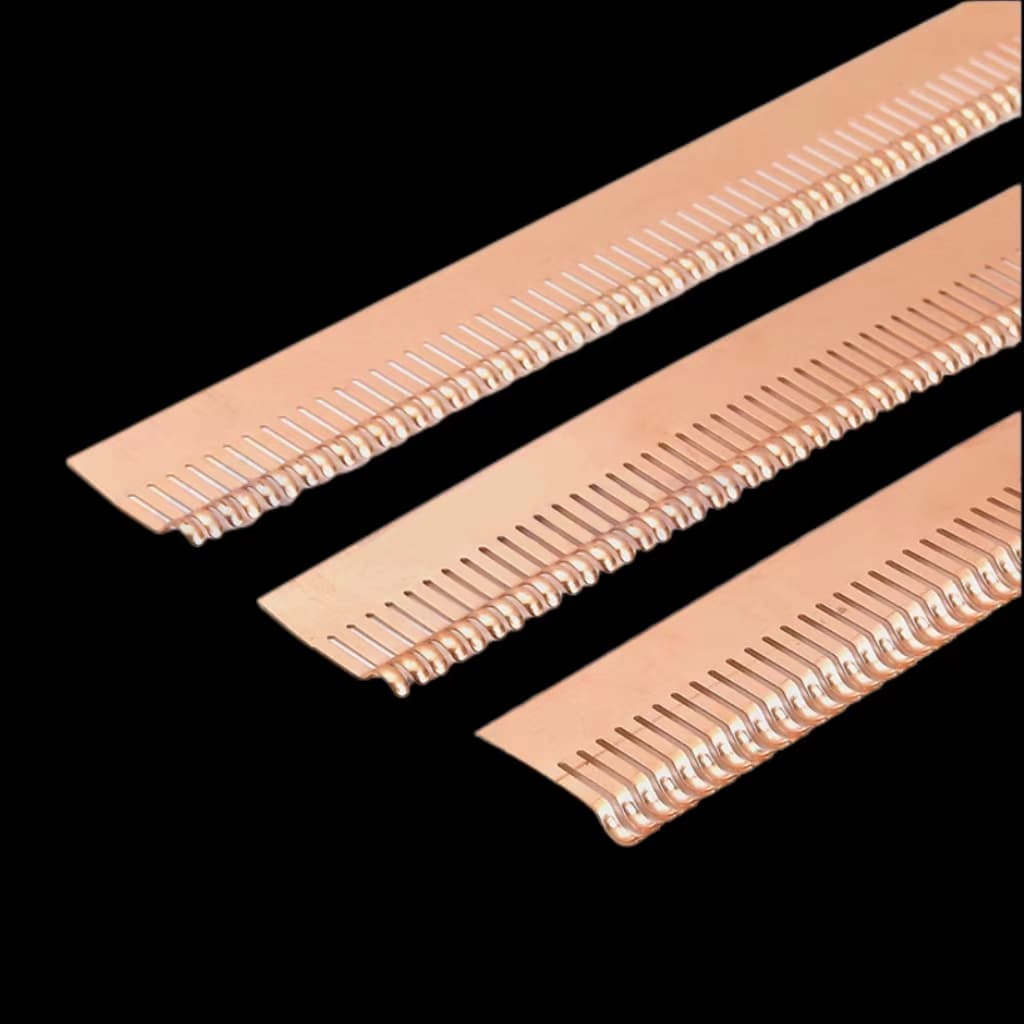

Handa twisted mounting shielding fingerstrip has a reasonably twisted design and various advantages.

Save space

High EMI shielding performance

Easy and secure installation

Easy plating and welding

High compression resistance

Easy plating and welding

The plating process of various materials can be customized

Applications

The structural design of Handa twisted mounting shielding fingerstrip has the characteristics of twisting and torsional, which is very suitable for use in a variety of narrow installation space applications.

Shield panel

Sealed shield case

Box with flat partition

Electronic product housing

Shielded cabinet with panel dividers

Telecommunication base station equipment

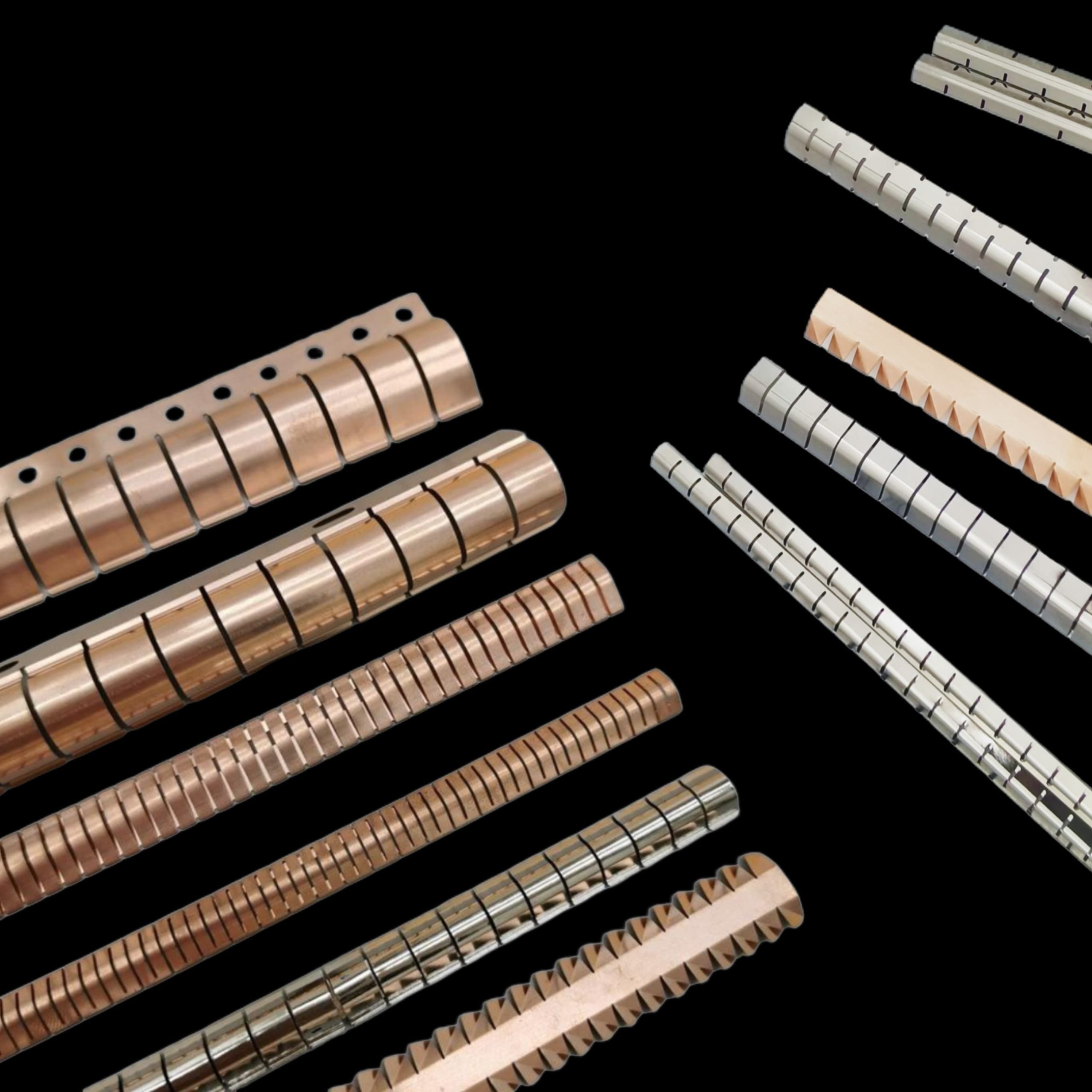

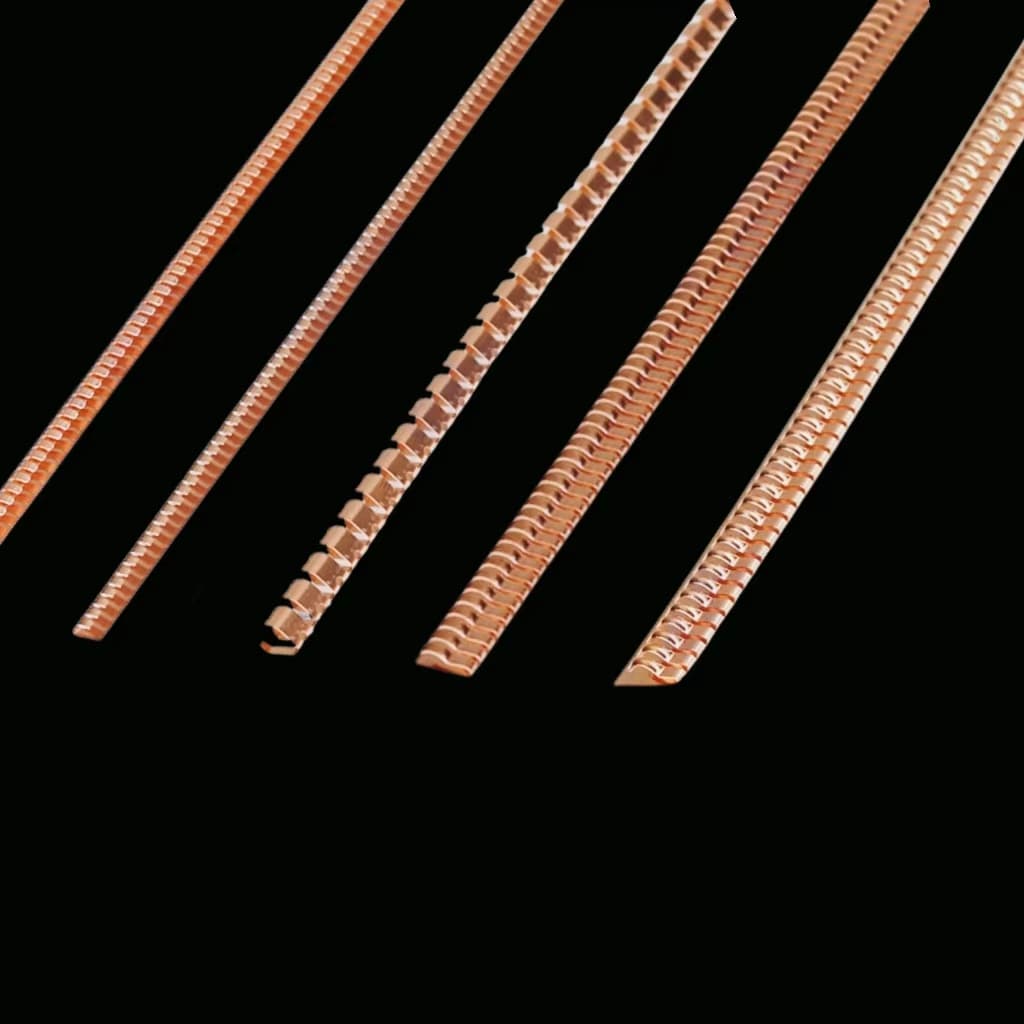

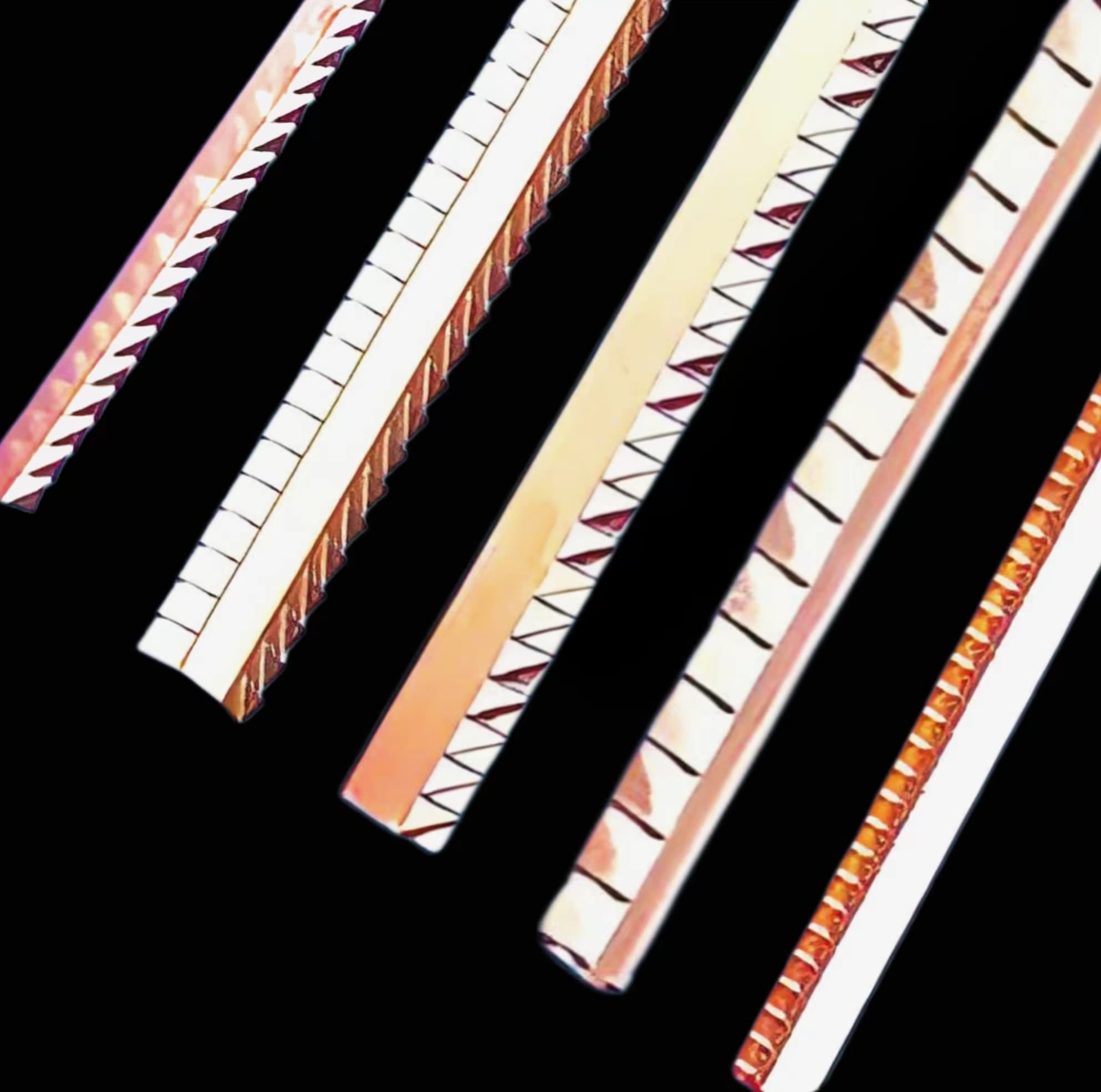

Material and plating

Handa twisted mounting shielding fingerstrips are available in the following materials.They can also be customized according to your requirement for different applications.

Beryllium-copper

Stainless steel

Beryllium-copper tin plated

Phosphorous bronze

Beryllium-copper nickle plated

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.

RECENT PRODUCT

-

Twisted mounting shielding fingerstrips IntroductionWhat are Twisted Mounting Shielding Fingerstrips?Key Features1. Twisted Design for Maximum Flexibility2. Exceptional Electrical Conductivity3. Durable and Resilient Construction4.......