Спиральные трубки с электромагнитным экранированием для вакуумного оборудования

Спиральные трубки для электромагнитного экранирования - это специально разработанные компоненты, которые предотвращают воздействие электромагнитных помех (ЭМП) на чувствительное оборудование. Эти трубки разработаны для обеспечения надежного экранирования в различных областях применения, особенно в средах, где важна высокая точность, например в вакуумных камерах, электронных устройствах и научных приборах.

Спиральные трубки с электромагнитным экранированием для вакуумного оборудования

Введение:

В современных высокотехнологичных отраслях электромагнитные помехи (ЭМП) представляют собой серьезную проблему, особенно для чувствительного оборудования, такого как вакуумные системы, точные приборы и электронные устройства. ЭМИ могут привести к искажению сигнала, потере данных и сбоям в работе оборудования, поэтому очень важно защититься от таких помех. Одним из наиболее эффективных способов предотвращения ЭМИ является использование спиральные трубки для электромагнитного экранирования (также известный как Спиральные трубки для защиты от электромагнитных помех или экранирующие спиральные трубки). Эти трубки обеспечивают улучшенную защиту в различных средах, включая вакуумные системы.

В этой статье мы рассмотрим роль спиральных трубок для электромагнитного экранирования в вакуумном оборудовании, их особенности, материалы, применение и преимущества. Представленная здесь информация призвана помочь вам понять важность экранирования электромагнитных помех в прецизионном оборудовании и то, как эти трубки могут оптимизировать производительность, снизить уровень помех и увеличить срок службы оборудования.

Оглавление

Что такое электромагнитные экранирующие спиральные трубки для вакуумного оборудования?

Электромагнитные экранирующие спиральные трубки для вакуумного оборудования - это специально разработанные компоненты, которые предотвращают воздействие электромагнитных помех (EMI) на чувствительное оборудование. Эти трубки разработаны для обеспечения надежного экранирования в различных областях применения, особенно в средах, где важна высокая точность, например в вакуумных камерах, электронных устройствах и научных приборах.

В основе конструкции спиральных трубок для электромагнитного экранирования лежит непрерывная спираль или спиральная структура, которая увеличивает площадь поверхности для эффективного экранирования. Такая спиральная форма помогает поглощать и перенаправлять электромагнитные волны, не позволяя им проникать внутрь трубки и воздействовать на внутренние компоненты оборудования. В результате они обеспечивают превосходную защиту от электромагнитных помех, что очень важно для поддержания точности и надежности чувствительных устройств.

Основные характеристики спиральных трубок с электромагнитным экранированием для вакуумного оборудования

- Превосходные характеристики экранирования электромагнитных помех: Основная функция электромагнитных экранирующих спиральных трубок для вакуумного оборудования заключается в блокировании или ослаблении электромагнитного излучения. Материалы, используемые в конструкции этих трубок, такие как нержавеющая сталь, медные сплавы, и сплавы на основе никеля-известны своей высокой электропроводностью и способностью эффективно отражать и поглощать электромагнитные волны.

- Совместимость с вакуумом: Вакуумная среда представляет собой уникальную проблему из-за экстремальных условий, которые могут повлиять на материалы и их характеристики. Спиральные трубки с электромагнитным экранированием, предназначенные для использования в вакуумном оборудовании, должны быть изготовлены из материалов, которые не только обеспечивают превосходное экранирование электромагнитных помех, но и сохраняют свои характеристики в условиях вакуума. Нержавеющая сталь 301, 304 и 316, бериллиевая медь, и сплавы на основе никеля широко используются благодаря своей долговечности, коррозионной стойкости и устойчивости в высокотемпературных средах.

- Прочность и долговечность: Помимо обеспечения экранирования электромагнитных помех, эти спиральные трубки должны выдерживать жесткие условия эксплуатации. Вакуумное оборудование часто работает в условиях высокого или низкого давления, поэтому экранирующие трубки должны выдерживать механические нагрузки, тепловые колебания и возможные химические взаимодействия. Высококачественные материалы обеспечивают длительный срок службы этих трубок, обеспечивая надежную защиту на протяжении всего срока службы оборудования.

- Настраиваемость и гибкость: Спиральные трубки для электромагнитного экранирования доступны в различных размерах и конфигурациях для удовлетворения специфических потребностей различного вакуумного оборудования. Независимо от того, имеете ли вы дело с небольшими компактными устройствами или крупными вакуумными камерами промышленного масштаба, эти трубки могут быть настроены для обеспечения оптимальных характеристик экранирования электромагнитных помех. Гибкость конструкции позволяет адаптировать их для использования в широком спектре приложений.

- Эффективная защита от электромагнитных помех в компактных помещениях: Одним из наиболее заметных преимуществ спиральных трубок для электромагнитного экранирования является их способность обеспечивать высокоэффективное экранирование ЭМИ в компактных пространствах. Их спиральная структура позволяет обеспечить эффективное экранирование в тех местах, где традиционные методы экранирования могут оказаться непрактичными. Это особенно важно в вакуумных системах, где пространство часто ограничено и требуется точное экранирование.

Материалы, используемые в электромагнитных экранирующих спиральных трубках для вакуумного оборудования

Характеристики спиральных трубок для электромагнитного экранирования во многом зависят от материалов, используемых в их конструкции. Материалы должны обладать высокой электропроводностью, коррозионной стойкостью и термической стабильностью. Ниже приведены некоторые из наиболее часто используемых материалов:

- Нержавеющая сталь (304, 316, 301): Нержавеющая сталь - широко используемый материал для электромагнитного экранирования благодаря отличному сочетанию электропроводности, коррозионной стойкости и механической прочности. 304 нержавеющая сталь обычно используется для общего экранирования, в то время как 316 нержавеющая сталь предпочтительнее в условиях, требующих повышенной коррозионной стойкости. Нержавеющая сталь 301 обладает хорошей гибкостью и прочностью, что делает его идеальным для гибкого экранирования ЭМИ в вакуумном оборудовании.

- Бериллиевая медь: Бериллиевая медь - еще один материал, часто используемый в производстве компонентов для экранирования электромагнитных помех. Этот материал обладает отличной электропроводностью, что делает его идеальным для приложений, требующих эффективного поглощения электромагнитных волн. Бериллиевая медь также обладает хорошей механической прочностью и устойчива к коррозии, что делает ее хорошо подходящей для высокопроизводительных экранирующих приложений в вакуумном оборудовании.

- Никелевые сплавы: Сплавы на основе никеля, такие как Инконель и МонельБлагодаря превосходной устойчивости к нагреву и коррозии они широко используются в высокотемпературных приложениях. Эти сплавы обеспечивают превосходные защитные характеристики в жестких условиях, включая вакуумные системы высокого давления.

- Медные сплавы: Медь известна своей высокой электропроводностью, что делает ее эффективным материалом для экранирования электромагнитных помех. Медные сплавы, в том числе с добавлением цинка или никеля, используются в тех случаях, когда требуется высокая электропроводность и устойчивость к коррозии. Их часто выбирают за соотношение эффективности экранирования и стоимости материала.

Применение спиральных трубок с электромагнитным экранированием для вакуумного оборудования

Электромагнитные экранирующие спиральные трубки для вакуумного оборудования широко используются в различных областях, где необходима защита от электромагнитных помех, особенно в вакуумном оборудовании. Некоторые из основных областей применения включают:

- Вакуумные камеры и насосы: В вакуумных системах электромагнитные помехи могут нарушить работоспособность оборудования и снизить точность измерений. Экранирующие спиральные трубки используются в вакуумных камерах, насосах и других критически важных компонентах для предотвращения влияния внешних электромагнитных помех на работу системы.

- Электронные устройства и датчики: Прецизионные электронные устройства, включая датчики и измерительные приборы, часто используются в вакуумных системах и очень восприимчивы к электромагнитным помехам. Спиральные трубки для электромагнитного экранирования используются для защиты этих чувствительных компонентов от помех, обеспечивая точную и надежную работу устройств.

- Научное и медицинское оборудование: В научных исследованиях и медицинских приложениях точный сбор данных и функциональность приборов имеют решающее значение. Вакуумное оборудование, используемое в таких областях, как спектроскопия, физика частиц и медицинская визуализация, должно быть защищено от электромагнитных помех для обеспечения точности показаний и предотвращения сбоев в работе. Спиральные трубки с электромагнитным экранированием являются экономически эффективным и надежным решением для таких задач.

- Аэрокосмические исследования и освоение космоса: В аэрокосмической отрасли и при освоении космоса электронные системы должны быть защищены от электромагнитного излучения, чтобы обеспечить надежную работу в космических условиях. Электромагнитные экранирующие спиральные трубки для вакуумного оборудования используются в космических кораблях и спутниковых системах для защиты чувствительного оборудования от внешних помех, обеспечивая тем самым точность работы бортовых приборов и систем связи.

Преимущества спиральных трубок с электромагнитным экранированием для вакуумного оборудования

- Высокая эффективность экранирования: Спиральная конструкция этих трубок обеспечивает превосходные возможности экранирования за счет увеличения площади поверхности для поглощения электромагнитных волн. Непрерывная структура спирали обеспечивает постоянное покрытие, эффективно блокируя попадание ЭМИ на чувствительные компоненты внутри вакуумного оборудования.

- Повышенная долговечность оборудования: Предотвращая негативное воздействие электромагнитных помех, экранирующие спиральные трубки помогают продлить срок службы вакуумного оборудования и чувствительных приборов. Их прочные материалы и конструкция обеспечивают защиту оборудования на долгие годы, снижая необходимость в частом обслуживании или замене.

- Экономически эффективное решение: Спиральные трубки для электромагнитного экранирования представляют собой экономически эффективное решение для предотвращения ЭМИ в вакуумном оборудовании. Гибкая конструкция и широкая доступность делают их доступным выбором для целого ряда применений, от небольших лабораторных приборов до крупных промышленных систем.

- Компактный и легкий: Свернутая структура экранирующих трубок позволяет обеспечить эффективную защиту в компактных пространствах, где другие типы экранирования могут быть неэффективны. Легкая конструкция также позволяет легко устанавливать их, не увеличивая вес и объем системы.

- Настройка и адаптация: Спиральные трубки для электромагнитного экранирования могут быть изготовлены в соответствии с конкретными потребностями различного вакуумного оборудования. Независимо от того, требуется ли вам определенный размер, форма или материал, эти трубки могут быть подобраны таким образом, чтобы обеспечить оптимальную защиту вашей системы.

Заключение

Спиральные трубки для электромагнитного экранирования играют важнейшую роль в защите чувствительного оборудования от электромагнитных помех (ЭМП) в вакуумных системах и других высокоточных средах. Обеспечивая надежную и долговечную защиту, эти трубки гарантируют, что вакуумное оборудование и электронные приборы будут работать с максимальной точностью и эффективностью. Благодаря своим передовым характеристикам экранирования, долговечности и универсальности спиральные трубки для электромагнитного экранирования являются незаменимыми компонентами для широкого спектра приложений, включая научные исследования, медицинское оборудование, аэрокосмическую промышленность и многое другое.

По мере развития технологий потребность в эффективной защите от электромагнитных помех будет только расти. Спиральные трубки для вакуумного оборудования с электромагнитным экранированием - это эффективное и экономичное решение, которое гарантирует защиту вашего оборудования от разрушительного воздействия электромагнитных помех, помогая вам поддерживать оптимальную производительность и надежность даже в самых сложных условиях эксплуатации.Для получения дополнительной информации об электромагнитных экранирующих решениях вы можете посетить сайт Экранирующие спиральные трубчатые прокладки Handa Shielding для защиты от электромагнитных помех или связаться с нами.

Вам также может понравиться

-

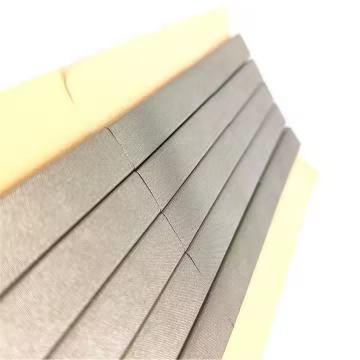

Спиральная прокладка Handa Flexi Shield с превосходной защитой от электромагнитных помех

Спиральная прокладка Handa Flexi Shield с превосходной защитой от электромагнитных помехЭкранирование EMI/EMC | Экранирование RFI | Прокладки EMI

Спиральная прокладка для экранирования радиочастот/электромагнитных помех

Спиральные прокладки Handa Flexi Shield Особенности конструкции Handa Flexi ShieldПрименение спиральных прокладок Handa Flexi ShieldСпецификации спиральных прокладок Handa Flexi ShieldУчет особенностей конструкции спиральных прокладок Handa Flexi ShieldКлючевые преимущества спиральных прокладок Handa Flexi ShieldВозможности персонализации для Handa......

-

Экранирующие прокладки из вязаной проволочной сетки EMI/RFI с высокой эффективностью экранирования

Экранирующие прокладки из вязаной проволочной сетки EMI/RFI с высокой эффективностью экранированияПолоски для пальцев

Прямоугольная экранирующая планка

Вязаная проволочная сетка EMI/RFI экранирующие прокладки Введение в вязаную проволочную сетку EMI/RFI экранирующие прокладкиЧто такое экранирование EMI и RFI? Как работает вязаная проволочная сетка EMI/RFI экранирующие прокладкиМатериалы, используемые в вязаной проволочной сетке EMI/RFI экранирующие прокладкиПреимущества вязаной проволочной сетки EMI/RFI экранирующие прокладки......

-

Высокотемпературные стойкие прокладки EMI для различных промышленных и технологических применений

Высокотемпературные стойкие прокладки EMI для различных промышленных и технологических примененийРешения и материалы для экранирующих прокладок

Высокотемпературная прокладка для защиты от электромагнитных полей

Высокотемпературные устойчивые прокладки EMI в различных промышленных и технологических областях применения Введение в высокотемпературные устойчивые прокладки EMIКлючевые особенности высокотемпературных устойчивых прокладок EMIКонструкция и материалыОбласти примененияКлючевые характеристикиПроцесс производстваЛучшие практики установки и обслуживанияСравнение с другими типами EMI......

-

Высокотемпературные прокладки EMI с длительным сроком службы

Высокотемпературные прокладки EMI с длительным сроком службыРешения и материалы для экранирующих прокладок

Высокотемпературная прокладка для защиты от электромагнитных полей

Высокотемпературные устойчивые прокладки для защиты от электромагнитных помех - Handa Shielding Введение в высокотемпературные устойчивые прокладки для защиты от электромагнитных помехКлючевые особенности высокотемпературных устойчивых прокладок для защиты от электромагнитных помехКонструкция и материалыОсновной материал: Пена FUBAКондуктивная металлизированная тканьКлеевая технологияПрименение высокотемпературных противоэлектрических прокладокКлючевые характеристикиПроцесс производстваЛучшие методы установки и.......

-

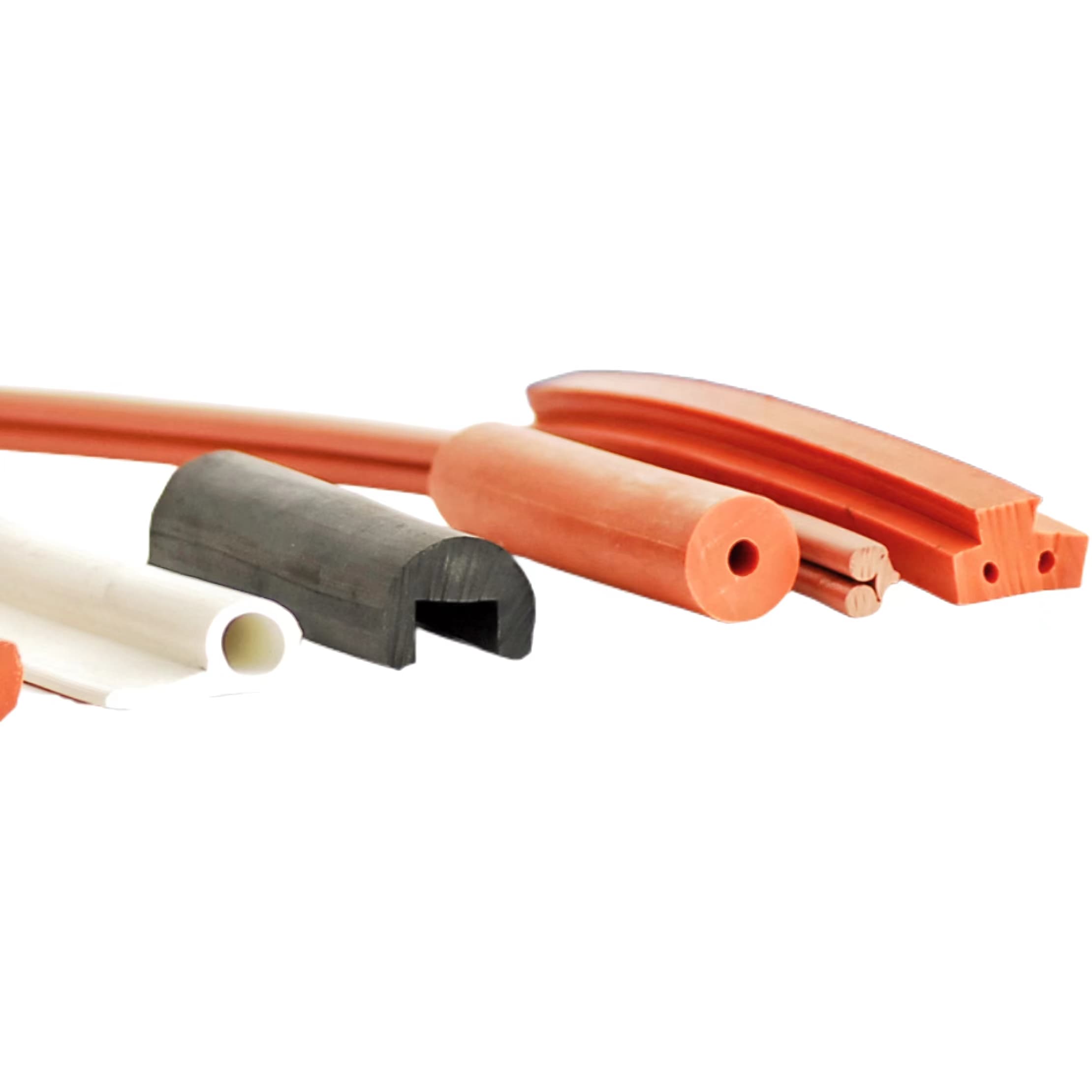

Электропроводящие резиновые профили с токопроводящими свойствами

Электропроводящие резиновые профили с токопроводящими свойствамиРешения и материалы для экранирующих прокладок

Электропроводящие резиновые профили

Электропроводящие резиновые профили 1. Введение в электропроводящие резиновые профили2. Основные компоненты электропроводящих резиновых профилей2.1. Базовый резиновый материал2.2. Проводящие наполнители2.3. Добавки и наполнители для придания механических свойств3. Процесс производства электропроводящих резиновых профилей3.1. Компаундирование3.2. Формование3.3. Отверждение (вулканизация)3.4.......