Premium EMI Shielding Gaskets & RF Gasketing Solutions

We are a leading Chinese manufacturing corporation specializing in EMI shielding solutions. Handa Shielding specializes in electromagnetic shielding solutions, offering a range of high-quality products for various industries. Our expertise ensures reliable protection for electronic devices against electromagnetic interference, ensuring optimal performance.

EMI shielding products, services & materials

View All ProductsOur Custom Services

Professional Electromagnetic Shielding Solutions Provider.

Through professional electromagnetic shielding technology, keep your equipment stable and reliable in electromagnetic interference environments.

Our Products and Services

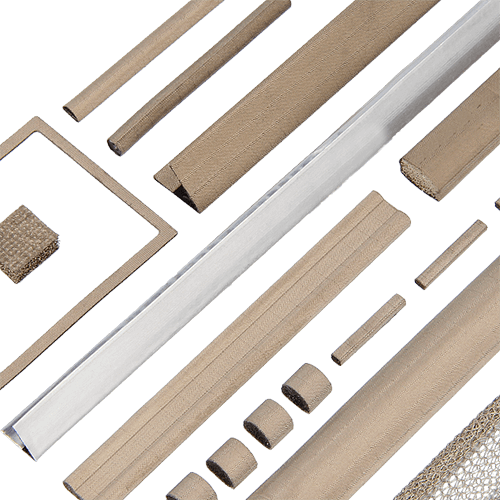

• Electromagnetic Shielding Products.

• Customized Solutions.

• Technical Support.

If you are interested in our electromagnetic shielding solutions or have any questions, directly contact us. We look forward to providing you with excellent electromagnetic shielding products and services.

RECENT PRODUCT

-

EMI Shielding Gasket Sample Request | Test Before You Specify Meta Description Submit an EMI shielding gasket sample request to evaluate material performance,......

-

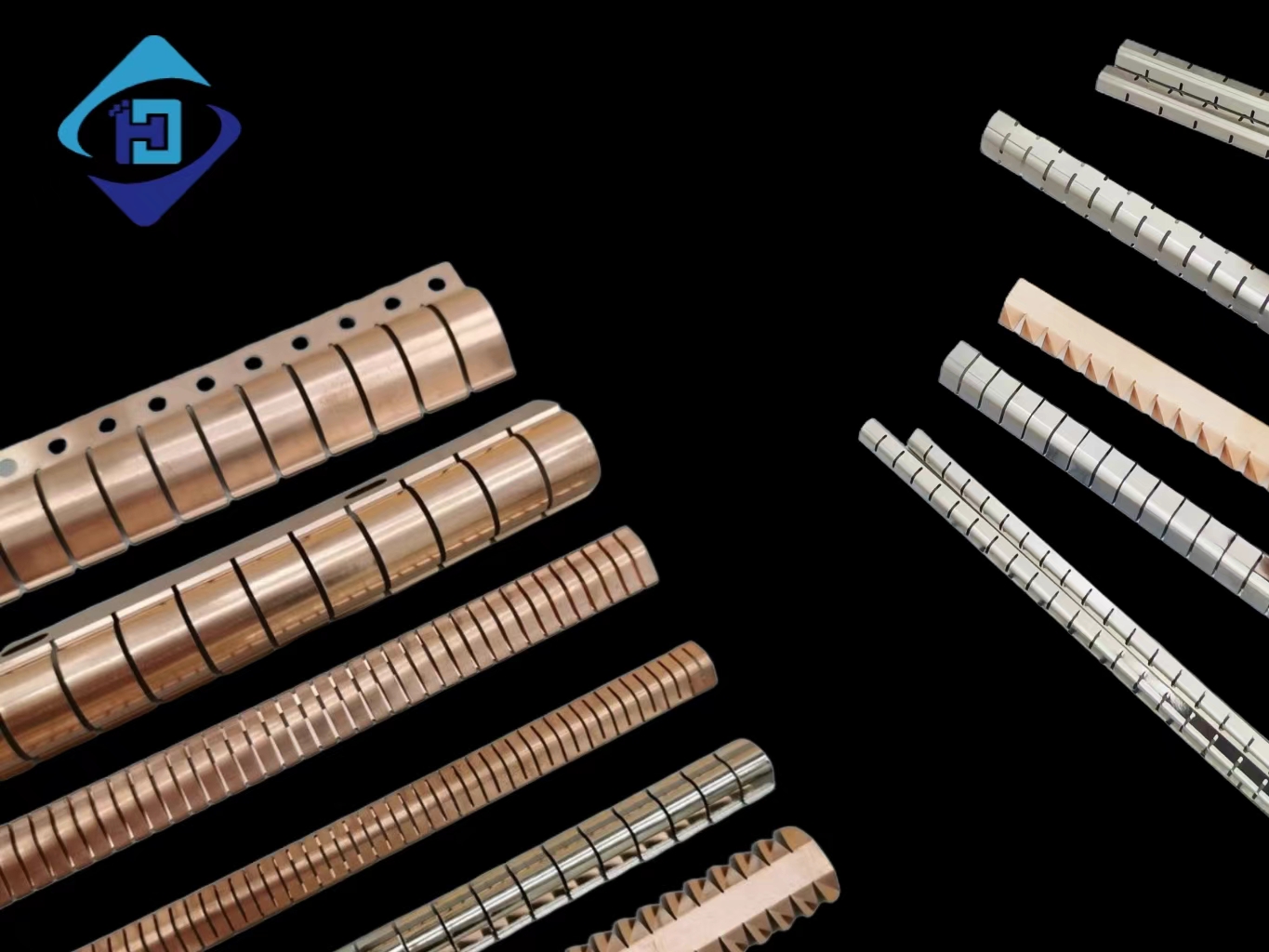

Custom canted coil springs offer tailored force, deflection, and durability for demanding applications. Learn key design considerations, materials, manufacturing processes, and quality controls......

-

Loss of force in canted coil springs explained. Learn the root causes, performance impacts, and proven engineering solutions to ensure long-term spring reliability.......

-

Canted coil spring for EMI shielding provide consistent contact force, superior conductivity, and long service life. Learn how they work, key advantages over......

-

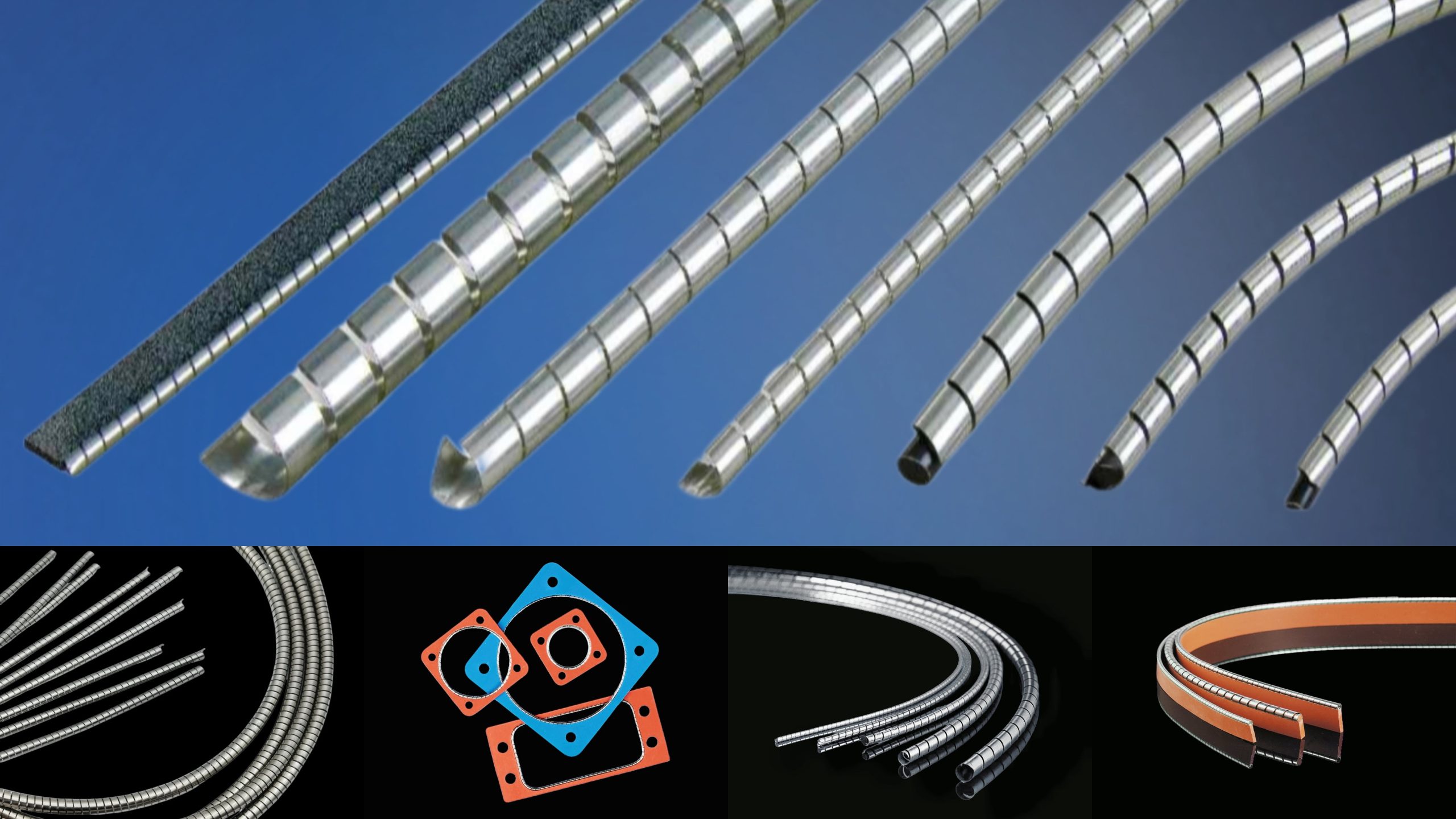

Discover HANDA’s RF/EMI Shielding Spiral Gasket made from premium Hastelloy C-276. Engineered for semiconductor CVD equipment, it delivers exceptional chemical resistance, high-temperature stability,......

-

Hunan Handa Spiral Spring EMI Shielding Solutions New Partnership Announcement: HANDA Spiral EMI Shielding Gaskets Solutions Now Available.As the demand for reliable electromagnetic......

-

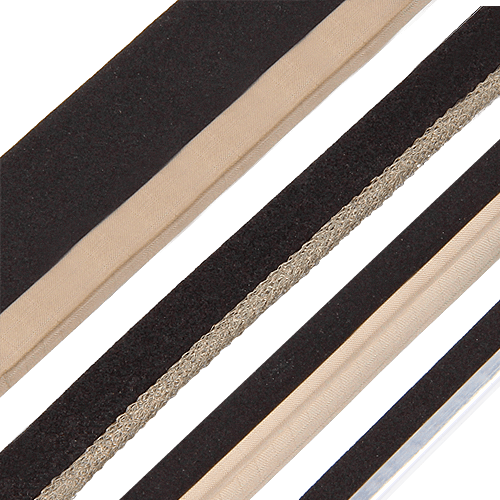

1. Introduction to Conductive Fabric2. Key Performance Advantages3. Applications in Electronics and Communication3.1 Consumer and Industrial Electronics3.2 5G and Telecommunication Systems3.3 Automotive Electronics3.4......

-

In high-voltage switchgear, GIS (Gas-Insulated Switchgear), and power transmission and distribution systems, electrical conducting springs have emerged as indispensable key conductive components in......

Resources

RECENT News

News Center

Explore the most recent news, insights, and perspectives from various industries.

View the recent list of industry news.