Knitted Wire Mesh EMI/RFI Shielding Gaskets with High Shielding Efficiency

Knitted wire mesh gaskets used for EMI (Electromagnetic Interference) and RFI (Radio Frequency Interference) shielding are essential components in protecting electronic devices and systems from interference that could affect their performance. These gaskets combine the mechanical advantages of knitted wire mesh with the ability to block or attenuate electromagnetic or radio frequency signals, providing a vital protective barrier. Their use in industries like telecommunications, aerospace, military, and consumer electronics is essential for ensuring that equipment operates within the required standards of electromagnetic compatibility (EMC) and does not cause unwanted emissions or vulnerability to external interference.

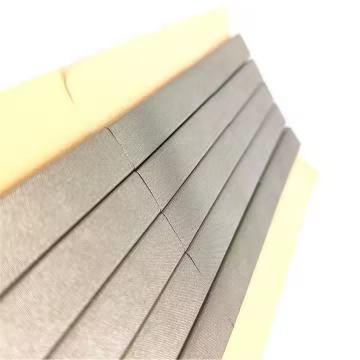

Knitted Wire Mesh EMI/RFI Shielding Gaskets

Table of Contents

Introduction to Knitted Wire Mesh EMI/RFI Shielding Gaskets

Knitted wire mesh gaskets used for EMI (Electromagnetic Interference) and RFI (Radio Frequency Interference) shielding are essential components in protecting electronic devices and systems from interference that could affect their performance. These gaskets combine the mechanical advantages of knitted wire mesh with the ability to block or attenuate electromagnetic or radio frequency signals, providing a vital protective barrier. Their use in industries like telecommunications, aerospace, military, and consumer electronics is essential for ensuring that equipment operates within the required standards of electromagnetic compatibility (EMC) and does not cause unwanted emissions or vulnerability to external interference.

An EMI/RFI shielding gasket made from knitted wire mesh provides a combination of flexibility, durability, and high shielding efficiency. It offers a practical and effective solution for achieving EMI/RFI shielding in devices and systems where protection from external signals or leakage of internal signals is required. This gasket type ensures that sensitive electronics and communication devices remain free from disturbances, allowing for proper operation in increasingly complex electromagnetic environments.

What is EMI and RFI Shielding?

EMI (Electromagnetic Interference) and RFI (Radio Frequency Interference) are disruptions that occur when unwanted electromagnetic signals interfere with the normal operation of electronic devices or systems. These interferences can originate from external sources, such as radio towers, power lines, or other electronic devices, or they can be emitted from the equipment itself. EMI and RFI can lead to several problems, including:

- Signal degradation in sensitive communication systems,

- Malfunctioning of electronic components and systems,

- Data loss or errors in computing systems,

- Unauthorized emissions, leading to breaches in privacy or security.

Shielding is the process of preventing these types of interference by using conductive materials that can block or redirect the electromagnetic waves, protecting the electronic systems from the negative effects of EMI/RFI. Shielding gaskets are used to form seals around electronic enclosures or mating surfaces, ensuring that these surfaces are electrically conductive, thereby preventing the leakage of electromagnetic signals and protecting against external interference.

How Knitted Wire Mesh EMI/RFI Shielding Gaskets Work

The operation of a knitted wire mesh EMI/RFI shielding gasket is based on the Faraday Cage Effect. This effect involves the use of conductive materials to create a barrier that can reflect, absorb, or dissipate electromagnetic waves, preventing them from entering or exiting the protected area. The knitted wire mesh, typically made from materials like stainless steel, copper, or nickel alloys, provides a combination of mechanical flexibility and excellent electrical conductivity, making it an ideal material for EMI/RFI shielding applications.

Here’s how the knitted wire mesh works in a gasket form:

- Conductivity: The mesh’s interwoven wire structure allows the gasket to conduct electromagnetic waves effectively, either absorbing or reflecting them based on the frequency of the interference. The metal wires in the mesh act as a conduit for the signals, preventing their transmission across the sealed gap.

- Contact Pressure: When a knitted wire mesh gasket is compressed between two surfaces, such as the housing of an electronic device, the mesh makes contact with both surfaces, ensuring that the shielded area is completely enclosed. The metal-to-metal contact creates a conductive path that redirects electromagnetic waves, minimizing interference.

- Shielding Effectiveness: The effectiveness of the knitted wire mesh EMI/RFI shielding gaskets in shielding depends on various factors, including the mesh density, wire material, thickness, and the frequency of the EMI/RFI signals. A higher-density mesh with tightly interwoven wires provides a more effective shield against higher frequencies, while a lower-density mesh may be more effective at attenuating lower frequencies.

- Flexibility: The knitted wire mesh gaskets maintain a high level of flexibility, allowing them to form reliable seals around irregular or uneven surfaces. This is particularly important when ensuring that the shield is maintained across all mating surfaces of enclosures or equipment.

- Environmental Resilience: Besides EMI/RFI shielding, knitted wire mesh gaskets are also resilient to environmental stresses such as temperature changes, moisture, and physical wear. This makes them ideal for protecting electronic devices in harsh conditions.

Materials Used in Knitted Wire Mesh EMI/RFI Shielding Gaskets

The materials chosen for knitted wire mesh EMI/RFI shielding gaskets play a significant role in their performance, as the materials need to have excellent electrical conductivity and mechanical strength. The most commonly used materials for these gaskets include:

- Stainless Steel:

- Properties: Stainless steel is a popular choice for EMI/RFI shielding because it offers both excellent corrosion resistance and good electrical conductivity. Stainless steel’s resistance to oxidation and wear makes it highly durable in harsh environments, making it suitable for use in outdoor or industrial applications.

- Applications: It is commonly used in industries where high temperature, humidity, or corrosion is expected, such as in military, aerospace, automotive, and industrial equipment.

- Copper:

- Properties: Copper is an excellent conductor of electricity and has superior shielding properties, especially for higher frequencies. Copper’s relatively high cost and lower corrosion resistance compared to stainless steel are often mitigated by using surface coatings or by choosing copper alloys that resist corrosion.

- Applications: Copper or copper alloys are often used in sensitive electronic equipment that needs high-performance shielding, particularly in telecommunications, computing, and medical devices.

- Nickel Alloys:

- Properties: Nickel alloys, such as Monel and Inconel, are used for high-temperature applications where stainless steel or copper would not perform well. Nickel alloys are highly resistant to oxidation and are excellent at shielding EMI/RFI in harsh conditions.

- Applications: These alloys are found in aerospace, military, and automotive applications where both EMI shielding and high-temperature resistance are critical.

- Aluminum:

- Properties: Aluminum is less expensive than copper and stainless steel but offers good shielding properties for many general-purpose applications. It is lightweight and has decent corrosion resistance.

- Applications: Aluminum is often used in consumer electronics, power supplies, and in environments where a lighter and less costly shielding material is sufficient.

- Silver-Plated Materials:

- Properties: Silver-plated wires or mesh offer exceptional conductivity and corrosion resistance, providing excellent shielding effectiveness, especially in high-frequency ranges.

- Applications: Silver-plated gaskets are used in high-performance, high-frequency applications such as in military, telecommunications, and aerospace electronics.

Advantages of Knitted Wire Mesh EMI/RFI Shielding Gaskets

Knitted wire mesh EMI/RFI shielding gaskets offer several significant advantages, making them a preferred choice for many industrial and commercial applications. Some of the main benefits include:

- Excellent Shielding Effectiveness:

- The combination of conductivity, mesh density, and material choice makes knitted wire mesh gaskets highly effective at attenuating a wide range of EMI/RFI frequencies. They can provide shielding across a broad spectrum, ensuring protection from various types of electromagnetic interference.

- Flexibility and Formability:

- The knitted wire structure allows the gaskets to maintain flexibility while ensuring a tight seal around irregularly shaped or uneven surfaces. This ability to conform to different geometries and pressures makes them ideal for use in complex, compact, or customized electronic designs.

- Durability and Longevity:

- Knitted wire mesh gaskets are durable and resistant to wear, corrosion, and environmental stressors such as temperature extremes and humidity. Their robustness makes them suitable for long-lasting protection in harsh operating conditions.

- High Compression Resistance:

- Knitted wire mesh gaskets maintain excellent sealing performance even under significant compression. The materials used allow the gasket to return to its original shape, ensuring continued EMI/RFI shielding without degradation over time.

- Customization:

- Knitted wire mesh gaskets can be manufactured in a variety of shapes, sizes, and configurations to meet specific sealing and shielding requirements. The material’s adaptability makes it easy to create custom solutions for different applications.

- Low Maintenance:

- Knitted wire mesh EMI/RFI shielding gaskets require minimal maintenance once installed, offering a long service life with little risk of failure due to material fatigue, corrosion, or sealing performance degradation.

- Cost-Effective:

- While materials like copper or silver can be more expensive, knitted wire mesh EMI/RFI shielding gaskets made from stainless steel or aluminum are relatively cost-effective. They offer high performance at a reasonable price, especially for commercial or industrial applications.

Applications of Knitted Wire Mesh EMI/RFI Shielding Gaskets

Knitted wire mesh EMI/RFI shielding gaskets are used across a wide range of industries and applications, including:

- Telecommunications:

- In telecommunications equipment, these gaskets are used to prevent interference between different systems and to shield devices from external signals. They ensure that sensitive communication systems operate without degradation due to EMI/RFI.

- Aerospace:

- Aerospace applications require components that can perform under extreme conditions. Knitted wire mesh gaskets are used to shield aircraft electronics from external EMI, ensuring the safe and reliable operation of avionics systems.

- Medical Devices:

- In medical equipment, EMI/RFI shielding is critical to ensure that devices such as pacemakers, defibrillators, and imaging systems do not suffer from external interference that could affect their performance or safety.

- Consumer Electronics:

- From smartphones to laptops, knitted wire mesh gaskets are used to prevent EMI/RFI that could interfere with wireless communication and signal processing, ensuring that consumer electronics meet regulatory standards for electromagnetic compatibility.

- Automotive:

- Automotive systems, including navigation, communication, and control systems, rely on EMI/RFI shielding to prevent interference from nearby electrical systems or external sources. Knitted wire mesh gaskets are used to seal enclosures for these systems in cars and trucks.

- Military and Defense:

- The defense industry relies on EMI/RFI shielding for critical electronics in weapons systems, communication devices, and surveillance equipment. Knitted wire mesh gaskets provide robust protection against external interference and prevent the leakage of sensitive signals.

- Industrial Equipment:

- EMI/RFI shielding gaskets are used in industrial equipment, such as power supplies, controllers, and machinery, to prevent disruptions caused by electrical interference and to meet EMC regulations.

- Power Generation:

- In power generation and distribution systems, knitted wire mesh EMI/RFI shielding gaskets ensure that electronic systems do not emit interference that could affect nearby equipment, while also preventing external interference from impacting the operation of critical control systems.

Conclusion

Knitted wire mesh EMI/RFI shielding gaskets offer an effective solution for ensuring electromagnetic compatibility in a wide range of electronic devices and systems. With their flexibility, durability, and superior shielding performance, they are indispensable in industries such as telecommunications, aerospace, automotive, defense, medical, and consumer electronics. Their ability to provide reliable shielding against EMI/RFI interference makes them essential for the proper operation and longevity of sensitive electronic components and systems.

As electronics continue to evolve and become more sensitive to interference, knitted wire mesh gaskets will remain a critical technology for protecting devices from external and internal EMI/RFI disturbances, ensuring that devices function as intended in increasingly complex electromagnetic environments.

You May Also Like

-

High Temperature Resistant EMI Gaskets in Various Industrial and Technological Applications

High Temperature Resistant EMI Gaskets in Various Industrial and Technological ApplicationsShielding Gasket Solutions and Materials

High temperature resistant EMI gasket

High Temperature Resistant EMI Gaskets in Various Industrial and Technological Applications Introduction to High Temperature Resistant EMI GasketsKey Features of High Temperature Resistant EMI GasketsConstruction and MaterialsApplication AreasKey SpecificationsManufacturing ProcessBest Practices for Installation and MaintenanceComparison with Other Types of EMI......

-

High temperature resistant EMI gaskets with long-lasting performance

High temperature resistant EMI gaskets with long-lasting performanceShielding Gasket Solutions and Materials

High temperature resistant EMI gasket

High temperature resistant EMI gasket-Handa Shielding Introduction to High Temperature Resistant EMI GasketsKey Features of High Temperature Resistant EMI GasketsConstruction and MaterialsCore Material: FUBA FoamConductive Metallized FabricAdhesive TechnologyApplications of High Temperature Resistant EMI GasketsKey SpecificationsManufacturing ProcessBest Practices for Installation and......

-

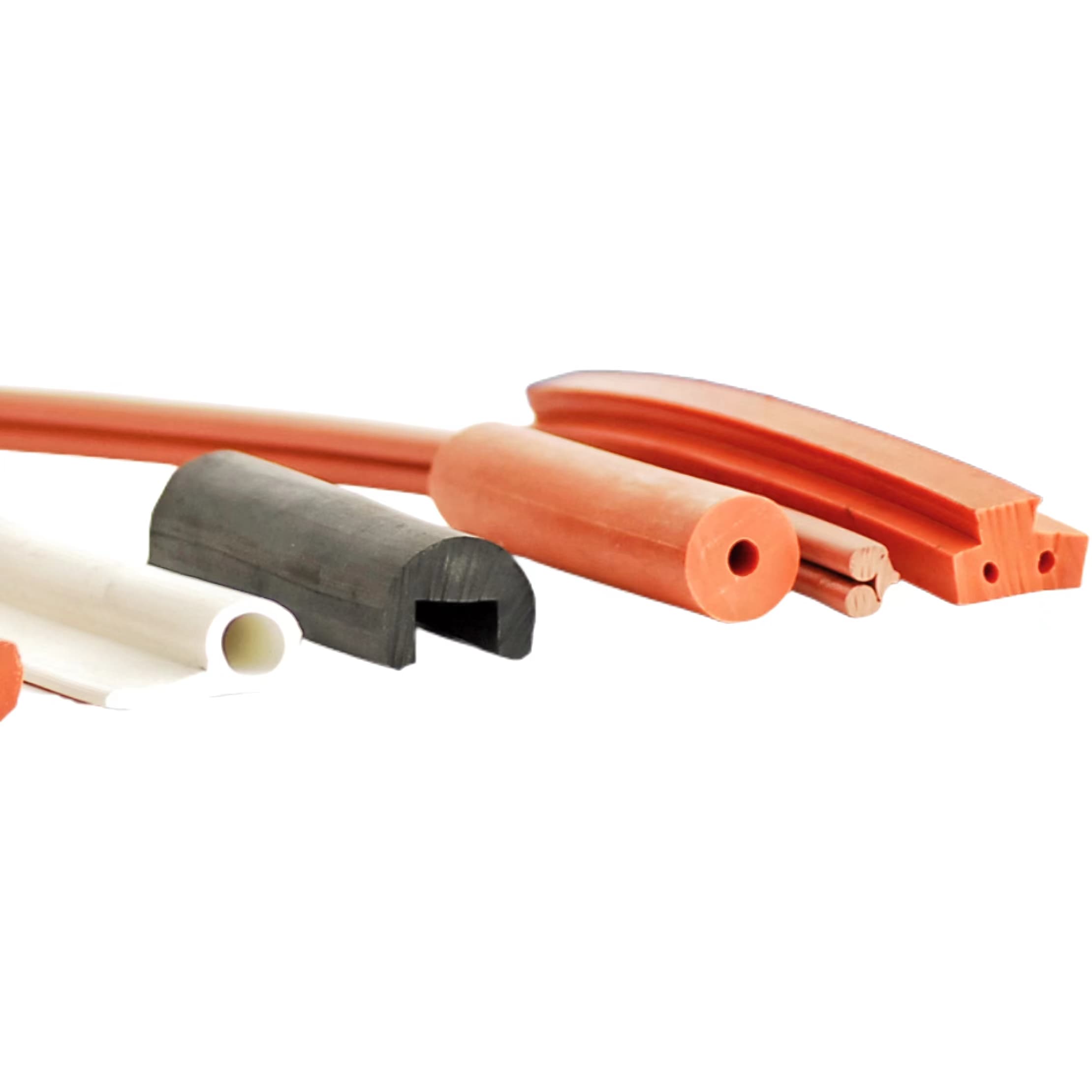

Electrically Conductive Rubber Profiles with Conductive Properties

Electrically Conductive Rubber Profiles with Conductive PropertiesShielding Gasket Solutions and Materials

Electrically conductive rubber profiles

Electrically conductive rubber profiles 1. Introduction to Electrically Conductive Rubber Profiles2. Key Components of Electrically Conductive Rubber Profiles2.1. Base Rubber Material2.2. Conductive Fillers2.3. Additives and Fillers for Mechanical Properties3. Manufacturing Process of Electrically Conductive Rubber Profiles3.1. Compounding3.2. Shaping3.3. Curing (Vulcanization)3.4.......

-

Flexible and Conductive Twisted Mounting Shielding Fingerstrips

Flexible and Conductive Twisted Mounting Shielding FingerstripsEMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

Twisted mounting shielding fingerstrips IntroductionWhat are Twisted Mounting Shielding Fingerstrips?Key Features1. Twisted Design for Maximum Flexibility2. Exceptional Electrical Conductivity3. Durable and Resilient Construction4. Compact and Space-Saving Profile5. Ease of InstallationMaterials and CoatingsBase MaterialsPlating OptionsBenefits of Twisted Mounting Shielding Fingerstrips1. Effective......

-

Handa Ultra Quick-Shield tin-plated stainless steel shielding gasket

Handa Ultra Quick-Shield tin-plated stainless steel shielding gasketEMI/EMC Shielding | RFI Shielding | EMI Gaskets

RF/EMI Shield Spiral Gasket

Handa Ultra Quick-Shield tin-plated stainless steel shielding gasket Introduction to EMI Shielding and Its ImportanceWhat Is the Handa Ultra Quick-Shield?Key Features of the Handa Ultra Quick-ShieldBenefits of Tin-Plated Stainless Steel Shielding Gaskets1. Enhanced Shielding Performance2. Corrosion and Wear Resistance3. Resilience......