HANDA RF/EMI Shielding Hastelloy Spiral Gasket for Semiconductor CVD Equipment

HANDA RF/EMI Shielding Hastelloy Spiral Gasket

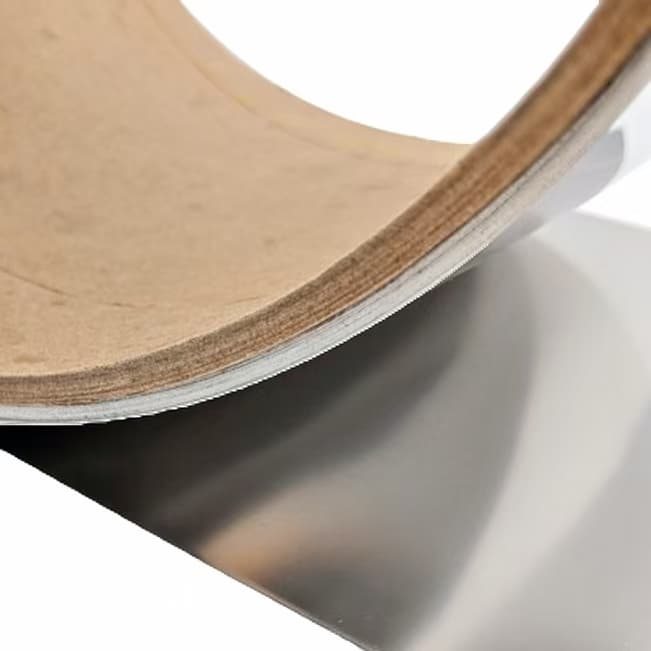

HANDA’s RF/EMI shielding spiral gasket is constructed from high-grade Hastelloy C-276 strip, offering exceptional corrosion resistance and thermal stability. Designed for semiconductor CVD and plasma-based equipment, this gasket provides robust electromagnetic interference suppression while maintaining secure mechanical sealing under high temperatures and aggressive chemical exposure.

Featuring a precision-engineered spiral structure, the gasket ensures consistent contact force, reliable conductivity, and long-term resilience in corrosive, RF-sensitive, and high-vacuum environments. It effectively blocks RF/EMI noise, enhances chamber performance, and supports process stability in critical semiconductor manufacturing applications.

Ideal for:

- CVD / PECVD / LPCVD chambers

- Plasma process modules

- High-temperature vacuum seals

- Corrosive gas handling systems

- RF-sensitive interfaces and enclosures

HANDA offers customization in strip thickness, dimensions, and spiral configurations to meet specific equipment requirements.

Discover HANDA’s RF/EMI Shielding Spiral Gasket made from premium Hastelloy C-276. Engineered for semiconductor CVD equipment, it delivers exceptional chemical resistance, high-temperature stability, and reliable RF/EMI attenuation for demanding plasma and vacuum process environments.

HANDA proudly introduces its latest high-performance innovation: the RF/EMI Shielding Hastelloy Spiral Gasket, specifically engineered for next-generation semiconductor CVD (Chemical Vapor Deposition) systems.

This new product combines advanced electromagnetic shielding capability, exceptional sealing reliabilityそして extreme chemical durability, making it a perfect fit for today’s demanding semiconductor manufacturing environments.

Semiconductor equipment is continuously evolving, requiring components capable of withstanding harsh plasmas, corrosive gases, thermal stress, and high-frequency electromagnetic interference. The HANDA Hastelloy C-276 spiral gasket was developed to solve these challenges with a single, integrated shielding and sealing solution.

1. Engineered for the Semiconductor Industry’s Most Extreme Conditions

Modern CVD tools operate under some of the harshest industrial conditions:

- High-temperature plasma reactions

- Rapid thermal cycling

- Chlorine, fluorine, and corrosive process gases

- Sensitive RF-powered plasma systems

- Precision vacuum sealing requirements

To address these challenges, HANDA’s spiral gasket uses Hastelloy C-276 strip, one of the most chemically and thermally resistant alloys available. The result is a gasket that offers stable mechanical integrity, reliable EMI shieldingそして long service life in environments where traditional gasket materials fail quickly.

2. Hastelloy C-276: The Ideal Material for Harsh Semiconductor Processes–RF/EMI Shielding

Hastelloy C-276 is a nickel-chromium-molybdenum superalloy widely used in chemical processing, aerospace, high-temperature systems, and semiconductor production due to its unmatched resistance properties.

2.1 Outstanding Chemical Resistance

Semiconductor CVD equipment often exposes materials to corrosive chemicals such as:

- Chlorine (Cl₂)

- Hydrogen chloride (HCl)

- Fluorinated gases (NF₃, CF₄, SF₆)

- Plasma by-products

- Oxidizing and non-oxidizing acids

Hastelloy C-276 resists all of these with exceptional stability, preventing:

- Pitting corrosion

- Stress corrosion cracking

- Material embrittlement

- Surface degradation that can cause particle generation

For semiconductor manufacturers, maintaining cleanliness and avoiding contamination is crucial. Using a chemically resistant gasket like HANDA’s Hastelloy spiral gasket ensures stable performance, longer replacement intervals, and greater equipment uptime.

2.2 Extreme Heat Resistance

CVD processes typically operate at elevated temperatures, and the gasket must maintain both mechanical strength and shielding integrity.

Hastelloy C-276 offers:

- Excellent thermal oxidation resistance

- Stable mechanical properties across wide temperature ranges

- Resistance to creep and deformation during long compressive loads

- Reliability during rapid heating and cooling cycles

This makes it ideal for:

- Plasma CVD

- PECVD and LPCVD

- MOCVD reactors

- High-temperature vacuum connections

- Exhaust and chemical gas feed systems

When temperature stability is essential, HANDA’s Hastelloy spiral gasket delivers predictable performance.

3. Reliable RF/EMI Shielding for High-Precision Semiconductor Equipment

In semiconductor CVD systems, RF and electromagnetic interference can significantly impact:

- Plasma stability

- Film deposition uniformity

- Sensor accuracy

- Data transmission within equipment

- Chamber-to-controller communication

3.1 How the HANDA Spiral Gasket Solves EMI Challenges

The HANDA Hastelloy spiral gasket is engineered to:

- Provide continuous conductive paths

- Reduce electromagnetic leakage

- Suppress unwanted RF energy

- Protect sensitive circuits and sensors

- Improve plasma process control consistency

By blocking RF/EMI noise at the source, the gasket helps ensure stable film quality, improved equipment performance, and reduced risk of production variation or downtime.

4. Advanced Structural Design for Protection, Durability & Performance

Beyond the alloy itself, the spiral coil architecture of HANDA’s gasket plays a critical role in its functionality.

4.1 Spiral Structure Benefits

- Highly resilient mechanical response

- Even distribution of contact force

- Consistent electrical conductivity

- Vibration tolerance and structural stability

- Long-term elasticity without excessive compression set

The gasket achieves a balanced combination of:

- シールド性能

- Mechanical sealing

- Chemical resistance

- High-temperature durability

This makes the HANDA spiral gasket suitable for long-term use in critical semiconductor modules that cannot afford performance degradation.

5. Application Scenarios in Semiconductor Manufacturing

The RF/EMI shielding Hastelloy spiral gasket is compatible with a wide range of semiconductor applications, including:

✔ CVD Equipment

- PECVD

- LPCVD

- MOCVD

- HDP-CVD

✔ Plasma Processing Chambers

- Etching equipment

- Plasma cleaning systems

- High-frequency plasma reactors

✔ Gas Delivery & Vacuum Systems

- High-temperature sealing points

- Corrosive chemical lines

- Plasma exhaust and abatement

✔ RF-Sensitive Modules

- Shielded communication ports

- RF-driven plasma modules

- Sensor housings

Wherever high-frequency shielding + chemical resistance + temperature stability are required at the same time, HANDA’s Hastelloy spiral gasket is a best-in-class option.

6. Key Advantages of HANDA’s Hastelloy Spiral Gasket

Below is a summary table highlighting why semiconductor manufacturers choose HANDA:

| 特徴 | Benefit |

| Premium Hastelloy C-276 strip | Extreme chemical & heat resistance |

| Spiral shielding design | Stable RF/EMI attenuation |

| High sealing reliability | Prevents leaks & contamination |

| High-temperature performance | Maintains elasticity & shielding |

| Designed for semiconductor use | Optimized for CVD chamber demands |

| Manufactured by HANDA | Excellent quality & application support |

7. Quality, Customization & Engineering Support from HANDA

HANDA provides:

7.1 Strict Quality Control

- Precise dimensional tolerances

- Material traceability

- Surface treatment and finishing options

- High repeatability in mass production

7.2 Customizable Solutions

We offer customizations in:

- Strip thickness

- Spiral width

- Gasket diameter

- Contact force levels

- Shielding performance ranges

This ensures perfect compatibility with your chamber design.

7.3 Engineering Support

HANDA’s technical team works closely with semiconductor OEMs to help:

- Select the right gasket material

- Optimize for chemical and thermal environment

- Evaluate shielding requirements

- Improve system reliability

From prototype to mass production, HANDA supports every stage of integration.

8. Improving Semiconductor Equipment Reliability with HANDA

Using the HANDA RF/EMI shielding Hastelloy spiral gasket provides several long-term benefits:

- Reduced risk of electromagnetic interference

- Fewer sealing failures in high-temperature systems

- Longer maintenance cycles

- More stable plasma deposition processes

- Improved equipment uptime

- Lower total cost of ownership

For semiconductor fabs aiming to improve tool reliability and wafer quality, this gasket provides a practical and high-impact improvement.

9. Contact HANDA for Technical Details & Product Information

For detailed specifications, performance data sheets, or quotations, please visit our product page or contact the HANDA technical sales team.

HANDA – Your Trusted Partner for High-Performance EMI Shielding and Chemical-Resistant Gasket Solutions in Semiconductor Manufacturing.

こちらもおすすめ

-

HANDA Spiral EMI Shielding Gaskets Solutions Now Available

HANDA Spiral EMI Shielding Gaskets Solutions Now AvailableRF/EMIシールドスパイラルガスケット

Handaスパイラルシールド

Hunan Handa Spiral Spring EMI Shielding Solutions New Partnership Announcement: HANDA Spiral EMI Shielding Gaskets Solutions Now Available.As the demand for reliable electromagnetic interference (EMI) protection continues to grow across electronics, telecommunications, automotive, and aerospace industries, manufacturers are seeking shielding......

-

High-Performance Conductive Fabric for EMI Shielding in Electronics and Communication Equipment

High-Performance Conductive Fabric for EMI Shielding in Electronics and Communication EquipmentEMIテープ、EMCホイル、導電性織物、半導電性不織布

Conductive cloth/fabrics

1. Introduction to Conductive Fabric2. Key Performance Advantages3. Applications in Electronics and Communication3.1 Consumer and Industrial Electronics3.2 5G and Telecommunication Systems3.3 Automotive Electronics3.4 Aerospace and Defense3.5 Wearable and Medical Devices4. Technical Specifications5. Why Choose Handa Shielding7. Conclusion 1. Introduction to......

-

Electrical Conducting Springs: The Core Component for Efficient Connections in the Power Industry

Electrical Conducting Springs: The Core Component for Efficient Connections in the Power IndustryHanda カントコイルスプリング

導電性スプリング

In high-voltage switchgear, GIS (Gas-Insulated Switchgear), and power transmission and distribution systems, electrical conducting springs have emerged as indispensable key conductive components in modern power equipment, thanks to their unique structural design and superior electrical performance. Hunan Handa Electronics Technology......

-

Conductive Cloth Tape: Structure, Uses, Characteristics & Buying Guide

Conductive Cloth Tape: Structure, Uses, Characteristics & Buying GuideEMIテープ、EMCホイル、導電性織物、半導電性不織布

導電性布テープ

Against the backdrop of the rapid development of modern electronic information technology, various electronic devices are emerging in an endless stream, and the electromagnetic environment is becoming increasingly complex. Electromagnetic interference not only affects the normal operation of equipment but......

-

優れた磁気特性を持つミューメタル箔

優れた磁気特性を持つミューメタル箔EMIテープ、EMCホイル、導電性織物、半導電性不織布

ミューフェロ/ミューメタルホイル

Abstract: This article delves into the production process of mu-metal foil, covering the entire workflow from raw material selection to finished product output. In the raw material preparation stage, strict control is imposed on high-purity iron, nickel, and other raw......