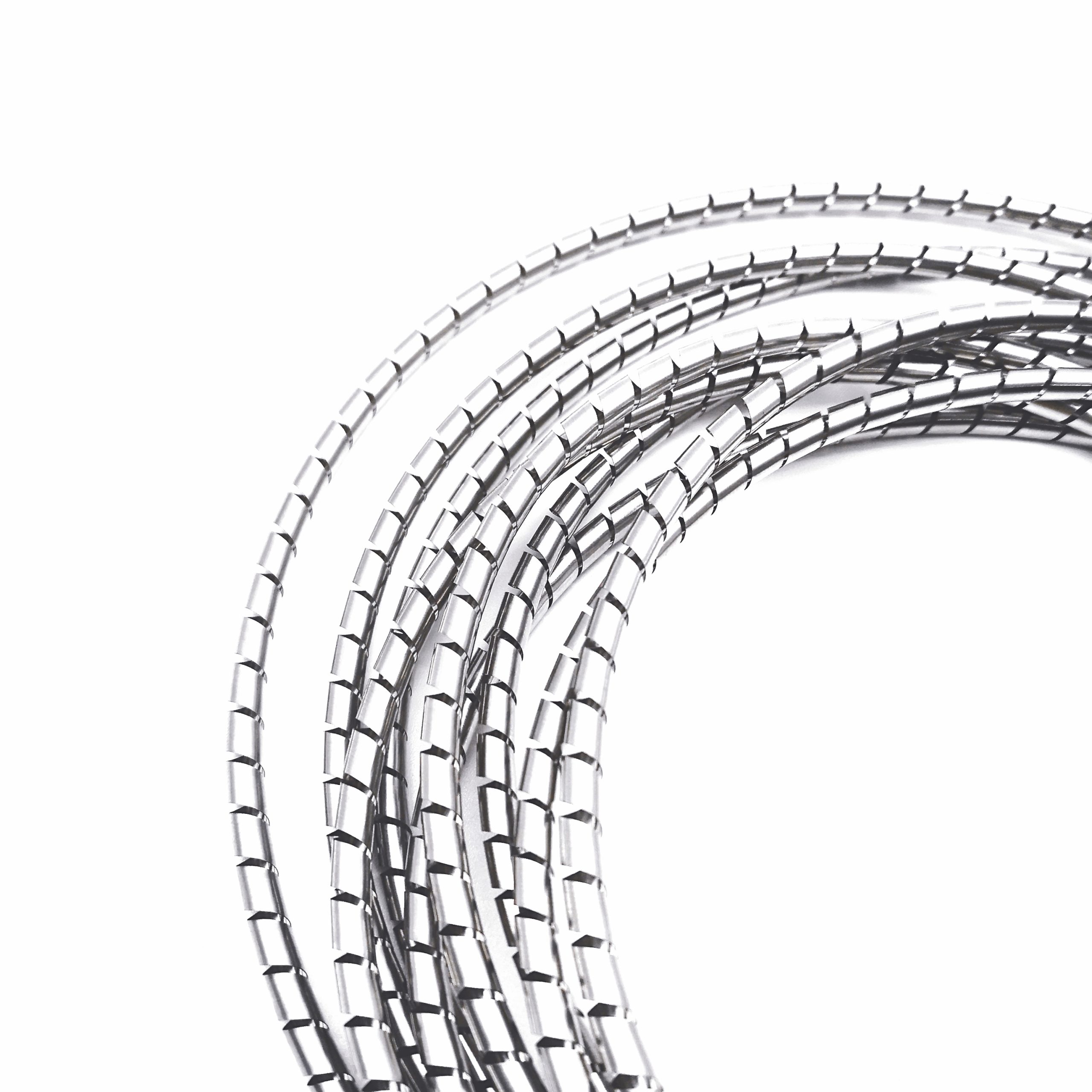

さまざまなタイプのEMIシールド・スパイラル管

中国湖南省郴州市

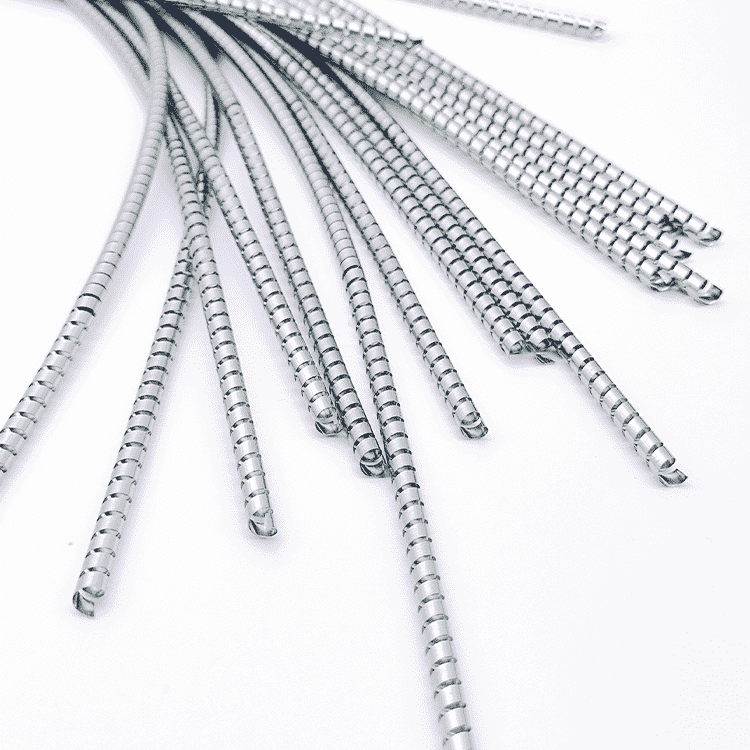

EMIシールドスパイラルチューブ-ハンドシールド

目次

(電磁干渉) EMIシールドスパイラルチューブ は、繊細な電子機器を不要な電磁波から保護するために設計された、洗練されたカテゴリーのコンポーネントです。これらの特殊なコンポーネントは、高度な材料科学と精密なエンジニアリングを組み合わせることで、厳しい環境下でも構造的な完全性を維持しながら、電磁干渉に対する効果的なバリアを作り出します。

基本的な種類と分類

- スタンダードフォースシリーズ(Sシリーズ) - 圧縮力4.8±15%・Kgf/in(外径3.2mm、25%圧縮)

- 直径の範囲1.0 ~ 12.0mm

- 材質SnメッキBeCu、NiメッキBeCu、ステンレススチール

- 用途バランスの取れた性能を必要とする一般産業用途

- ミディアム・フォース・シリーズ(Mシリーズ) - 圧縮力:2.0 ±15% Kgf/in

- 直径の範囲1.0 ~ 10.0mm

- 材質Sシリーズと同じ

- 用途中程度のシール圧を必要とする用途

- ローフォースシリーズ(Lシリーズ) - 圧縮力:0.4 ±15% Kgf/in

- 直径の範囲1.0 ~ 10.0mm

- 材質Sシリーズと同じ

- 用途精密機器と繊細なアプリケーション

EMIシールドスパイラルチューブの材料選択と特性

- ステンレス合金 - 301ステンレス鋼 - 高い強度と耐食性

- 優れたスプリング特性

- 良好な成形性

- 費用対効果の高いオプション

- 304ステンレス鋼

- 優れた耐食性- 食品および医療用途に最適

- 良好な溶接性

- 幅広く利用可能

- 316ステンレス鋼

- 耐食性の向上- 耐孔食性を向上させるモリブデンを配合

- 海洋環境に最適

- 304よりも高い強度

- 316Lステンレス鋼

- 316よりも炭素含有量が低い- 炭化物析出のリスクを低減

- 溶接性の向上

- 高純度アプリケーションに最適

- 17-7PHステンレス鋼

- 析出硬化合金- 高い強度対重量比

- 優れた耐食性

- 良好なバネ特性

- チタン合金 - Ti-6Al-4V (グレード5) - 高強度対重量比

- 優れた耐食性

- 生体適合性

- 良好な高温特性

- Ti-5Al-2.5Sn (グレード 6) - グレード 5 よりも高強度

- 高温特性の向上

- 良好な溶接性

- 優れた耐食性

- ベリリウム銅合金 - C17200(ベリリウム銅) - 高導電性

- 優れたスプリング特性

- 良好な耐食性

- 高い強度対重量比

- C17300(快削ベリリウム銅) - 加工性の向上

- わずかに低い導電率

- 良好なバネ特性

- 優れた耐食性

- エルジロイ®(コバルト-クロム-ニッケル) - 高い強度と耐食性

- 優れたスプリング特性

- 優れた耐疲労性

- 高い動作温度範囲

- インコネル®(ニッケルクロム) - インコネル 600 - 優れた耐食性

- 高温安定性

- 良好な溶接性

- 優れた耐酸化性

- インコネル718 - 高強度重量比

- 優れた耐食性

- 良好な成形性

- 高温特性

EMIシールドスパイラルチューブの産業別用途

- 航空宇宙・防衛 - 航空機エンジンおよび着陸装置システム

- 軍用通信機器

- 衛星部品

- 防衛エレクトロニクス

- 自動車部門 - 燃料噴射システム

- トランスミッション部品

- 排気システム

- 電子制御ユニット

- 医療機器 - 診断機器

- ポンプとバルブ

- 患者監視システム

- 手術器具

- 産業用途 - バルブアクチュエータ

- ロボットシステム

- 空気圧機器

- プロセス制御機器

技術仕様と必要条件

- 溝サイズ仕様 - 深さ (L):+0.05 /-0 mm

- 幅 (G):+0.18 / -0.13 mm

- 幅 (W):+0 / -0.05 mm

- パフォーマンス指標 - シールド効果>100dB以上(100MHz〜1GHz)

- 圧縮比:直径25%

- 温度範囲:-40℃~200

- 耐食性:塩水噴霧試験済み

製造工程

- 素材の選択と加工 - 原材料検査

- 材料の切断と準備

- 品質管理のチェックポイント

- 製造ステップ - 圧延と成形

- 表面処理

- サイズのカスタマイズ

- 品質管理

- パッケージング

EMIシールドスパイラルチューブの設置とメンテナンス

- 設置条件 - 清潔さ:表面にゴミがないこと

- アライメント:適切なポジショニングが必要

- 圧縮:推奨25%コンプレッションを維持

- 環境保護:動作条件を考慮する

- メンテナンス手順 - 定期点検スケジュール

- クリーニング・プロトコル

- パフォーマンス・モニタリング

- 交換基準

カスタマイズ・オプション

- サイズ・オプション - 直径の範囲0.8mmから50.0mm

- 長さカスタマイズ可能

- 特殊サイズも承ります

- 素材オプション - ベース素材

- 表面処理

- インナーコアの構成

- Oリング仕様

品質管理とテスト

- 環境試験 - 塩水噴霧試験

- 湿度暴露

- 温度サイクル

- パフォーマンス検証

- パフォーマンス検証 - シールド効果試験

- 機械的特性の検証

- 耐環境試験

- 長期信頼性評価

材料特性の比較

| 素材 | 強さ | 耐食性 | 温度範囲 | 春の物件 | コスト |

|---|---|---|---|---|---|

| 301 SS | ミディアム | グッド | -200°C~500°C | 素晴らしい | 低い |

| 304 SS | ミディアム | 非常に良い | -200°C ~ 800°C | 素晴らしい | ミディアム |

| 316 SS | ミディアム | 素晴らしい | -200°C ~ 800°C | 素晴らしい | 高い |

| 316L SS | ミディアム | 素晴らしい | -200°C ~ 800°C | 素晴らしい | 高い |

| 17-7PH SS | 高い | 非常に良い | -200°C~400°C | 素晴らしい | 高い |

| Ti-6Al-4V | 高い | 素晴らしい | -200°C~400°C | グッド | 非常に高い |

| C17200 | 高い | グッド | -200°C~300°C | 素晴らしい | 高い |

| エルジロイ | 非常に高い | 素晴らしい | -200°C~500°C | 素晴らしい | 非常に高い |

| インコネル600 | 高い | 素晴らしい | -200°C~1000°C | グッド | 非常に高い |

アプリケーション固有の推奨事項

- 医療機器 - インプラント器具Ti-6Al-4VまたはElgiloy

- 手術器具316Lまたは17-7PH

- 診断装置:304またはベリリウム銅

- 航空宇宙用途 - 構造部品:Ti-6Al-4Vまたはインコネル

- 電気部品:ベリリウム銅

- 高温用途インコネル

- 海洋環境 - 海水暴露:316/316Lまたはチタン

- 腐食性雰囲気: インコネル

- 構造部品:17-7PH

- 高温アプリケーション - 500℃以上インコネル

- 400-500°C:エルジロイ

- 400℃以下316/316L

EMIシールドスパイラルチューブ は、進歩する技術とともに進化し続け、繊細な電子機器を保護するためのますます洗練されたソリューションを提供しています。その多用途性、信頼性、有効性により、航空宇宙から医療機器に至るまで、現代の産業用途に不可欠なコンポーネントとなっています。慎重な材料選択、精密な製造、厳格な品質管理により、これらのコンポーネントは、厳しい環境下でも構造的完全性を維持しながら、電磁干渉に対する信頼性の高い保護を提供します。