How to Prevent Force Relaxation in Canted Coil Springs

Force relaxation in canted coil springs can lead to electrical failure, seal leakage, and reduced product life. Learn the engineering causes of force decay—including material creep, temperature effects, and groove design errors—and discover proven strategies to maintain stable long-term spring performance.

Force relaxation in canted coil springs can lead to electrical failure, seal leakage, and reduced product life. Learn the engineering causes of force decay—including material creep, temperature effects, and groove design errors—and discover proven strategies to maintain stable long-term spring performance.

はじめに

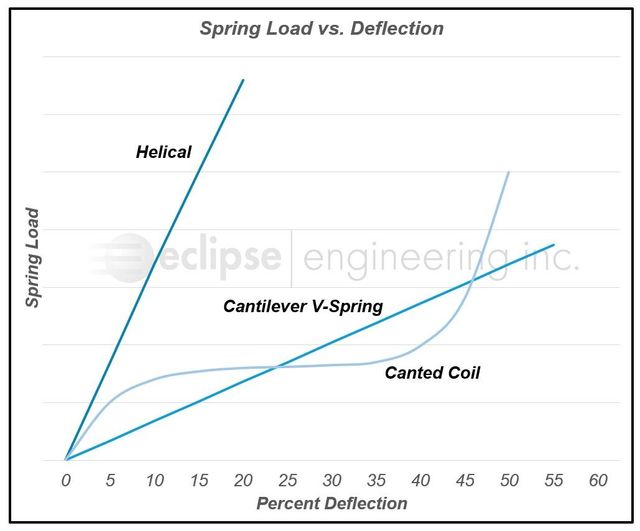

コイルスプリング are widely used in electrical contacts, EMI shielding, sealing systems, and precision mechanical assemblies because of their ability to deliver near-constant force over large deflection ranges.

However, one of the most common challenges engineers face is force relaxation—a gradual loss of contact force over time.

If left unaddressed, force relaxation can cause:

- Electrical intermittency

- Seal leakage

- Reduced vibration resistance

- Premature wear

- Field failures

Understanding why force relaxation occurs—and how to prevent it—is critical for achieving long-term reliability in demanding applications.

This article provides a detailed engineering guide to the root causes of force relaxation and practical methods to eliminate it.

What Is Force Relaxation in Canted Coil Springs?

Force relaxation refers to the progressive reduction of spring force under constant deflection.

Unlike sudden mechanical failure, relaxation happens slowly and often goes unnoticed until performance degrades.

In canted coil springs, relaxation primarily results from:

- Metallurgical changes under stress

- Elevated operating temperatures

- Continuous compression

- Improper groove geometry

- Material creep

Even a 10–20% force drop can be enough to compromise electrical conductivity or sealing integrity.

Primary Causes of Force Relaxation

1. Material Stress Relaxation and Creep

All metals experience stress relaxation when subjected to sustained load—especially at higher temperatures.

Lower-grade stainless steels are particularly vulnerable.

Typical force loss after 1000 hours under elevated temperature:

| 素材 | Approximate Force Loss |

|---|---|

| 302 Stainless Steel | 20–30% |

| 316ステンレス鋼 | 15–25% |

| ベリリウム銅 | 8–15% |

| エルジロイ | <8% |

| Inconel X-750 | <5% |

| MP35N | <5% |

High-performance alloys dramatically outperform standard materials in long-term stability.

2. Excessive Operating Temperature

Temperature accelerates atomic movement within metals, speeding up stress relaxation.

General guidelines:

- Below 100°C → minimal relaxation

- 100–150°C → moderate relaxation

- Above 150°C → rapid force decay (for stainless steels)

For high-temperature environments, nickel-based alloys such as Inconel® or MP35N are essential.

3. Improper Groove Design

Groove geometry directly determines how evenly load is distributed.

Common design errors include:

- Shallow groove depth

- Sharp corners

- Excessive radial clearance

- Non-parallel sidewalls

These cause localized overstress, leading to accelerated relaxation.

Poor grooves often reduce spring life by more than 40%.

4. Over-Compression During Assembly

Installing a spring beyond its recommended working deflection permanently damages its elastic structure.

This leads to:

- Immediate preload loss

- Nonlinear force behavior

- Rapid relaxation

Controlled compression during assembly is critical.

5. Manufacturing Variability

Inconsistent wire diameter, coil pitch, or heat treatment results in unpredictable force output.

Low-quality springs frequently exhibit large batch-to-batch force variation.

Professional manufacturers implement:

- Tight dimensional tolerances

- Heat stabilization

- Lot-level force testing

to ensure consistency.

Engineering Strategies to Prevent Force Relaxation

1. Select the Right Material for the Application

Material choice is the single most effective way to reduce relaxation.

Recommended materials by application:

| アプリケーション環境 | Recommended Alloy |

|---|---|

| High temperature | Inconel®, MP35N |

| Electrical contact | ベリリウム銅 |

| Corrosive environments | 316 Stainless |

| Long-term sealing | エルジロイ |

Upgrading material alone can improve force retention by up to 50%.

2. Optimize Groove Geometry

Proper groove design ensures uniform coil engagement.

Best practices:

- Groove depth = wire diameter × 0.85–0.95

- Corner radius ≥ 0.2 mm

- Controlled radial clearance

- Parallel groove walls

This prevents localized stress and improves long-term stability.

3. Define a Controlled Working Range

Rather than specifying only deflection, engineers should define:

- Initial preload

- Operating deflection window

- Target force range

This avoids pushing springs into nonlinear regions where relaxation accelerates.

4. Apply Heat Stabilization

High-quality canted coil springs undergo post-forming heat treatment to relieve residual stresses.

This significantly reduces early-life force decay.

5. Validate with Load-Deflection Testing

Professional suppliers perform:

- Load-deflection curve measurement

- Lot-based sampling

- Statistical process control

This ensures every production batch meets force requirements.

Comparison: Spring Types and Relaxation Behavior

| Spring Type | Force Stability | Deflection Range | Relaxation Resistance |

|---|---|---|---|

| Compression Spring | 低い | Narrow | 中程度 |

| Leaf Spring | 中程度 | Limited | 中程度 |

| Canted Coil Spring | 高い | Wide | 素晴らしい |

Properly engineered canted coil springs outperform traditional springs in long-term force stability.

Why Quality Manufacturing Matters

Low-cost springs often skip critical steps such as:

- Stress relief

- Precision forming

- Dimensional inspection

- Force verification

These shortcuts directly cause premature relaxation.

Engineering-grade suppliers invest in:

- CNC coil forming

- Vacuum heat treatment

- Laser measurement

- Full material traceability

This dramatically improves reliability.

結論

Force relaxation in canted coil springs is not unavoidable—it is an engineering challenge with clear solutions.

The primary contributors include:

- Material creep

- Elevated temperature

- Groove design errors

- Over-compression

- Manufacturing inconsistency

By applying proper material selection, precision groove design, controlled working ranges, and professional manufacturing processes, engineers can achieve:

✅ Stable contact force

✅ Reliable electrical performance

✅ Improved sealing integrity

✅ Extended service life

✅ Reduced field failures

When correctly designed, canted coil springs provide exceptional long-term force stability—even in extreme environments.