High Temperature Resistant EMI Gaskets in Various Industrial and Technological Applications

High-temperature resistant EMI (Electromagnetic Interference) gaskets are specialized components designed to provide effective electromagnetic shielding while withstanding extremely high temperatures. These gaskets play a crucial role in maintaining electromagnetic compatibility (EMC) in various industrial and technological applications, particularly in environments where both high temperatures and electromagnetic interference are present or anticipated.

High Temperature Resistant EMI Gaskets

in Various Industrial and Technological Applications

Table of Contents

Introduction to High Temperature Resistant EMI Gaskets

High-temperature resistant EMI (Electromagnetic Interference) gaskets are specialized components designed to provide effective electromagnetic shielding while withstanding extremely high temperatures. These gaskets play a crucial role in maintaining electromagnetic compatibility (EMC) in various industrial and technological applications, particularly in environments where both high temperatures and electromagnetic interference are present or anticipated. As industries increasingly rely on electronics and complex systems, the demand for efficient and durable shielding solutions continues to grow, making high-temperature resistant EMI gaskets essential for ensuring system integrity and reliability.

In this article, we will explore the key features, construction, materials, applications, specifications, and best practices for high-temperature resistant EMI gaskets. We will also compare them with other types of EMI gaskets and discuss the challenges, limitations, and future trends in this critical area of electronic component design.

Key Features of High Temperature Resistant EMI Gaskets

High-temperature resistant EMI gaskets possess several distinctive features that set them apart from standard EMI gaskets. These features ensure that the gaskets provide superior performance under challenging conditions while offering a balance between mechanical and electrical properties. Below are the key features of high-temperature resistant EMI gaskets:

- High Shielding Performance: The primary function of these gaskets is to block unwanted electromagnetic radiation and interference. Their design is optimized to provide exceptional electromagnetic shielding effectiveness, even in harsh environments where heat and interference levels are high. This shielding helps maintain the performance and integrity of sensitive electronic components and systems.

- Extremely Low Closure Force: These gaskets are engineered to exert minimal closure force, which prevents deformation or deflection of doors, covers, or other components they seal. This ensures that the gasket maintains its sealing integrity and shielding performance over time, even under high-pressure conditions or extreme temperature fluctuations.

- Ability to Seal Complex Gaps: High-temperature resistant EMI gaskets are designed to conform to intricate and irregular gaps, ensuring a reliable seal against both electrical noise and heat. This versatility is especially valuable in systems with complex geometries, such as enclosures with varying surface profiles or components subject to thermal expansion.

- Resistance to High Temperatures: One of the most significant features of these gaskets is their ability to withstand extreme temperatures. Depending on the specific formulation, these gaskets can typically operate in environments ranging from -40°C to 135°C, although some variants may tolerate even higher temperatures. This makes them suitable for use in industries where heat exposure is a concern, such as automotive, aerospace, and heavy machinery.

- Versatility Across Industries: High-temperature resistant EMI gaskets find application in a wide range of industries, including automotive, telecommunications, electronics, and building construction. Their ability to withstand high temperatures while providing effective electromagnetic shielding makes them invaluable in numerous applications where both performance and durability are required.

Construction and Materials

The construction of high-temperature resistant EMI gaskets involves a unique combination of materials that work together to provide both thermal and electromagnetic protection. The materials used in these gaskets are carefully selected for their performance characteristics in demanding environments. Below is a breakdown of the core materials and their roles in the gasket construction:

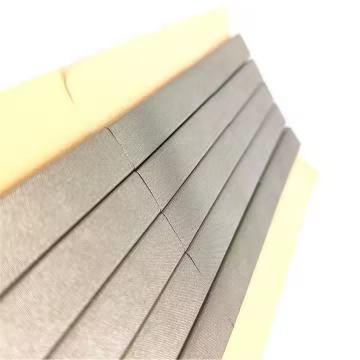

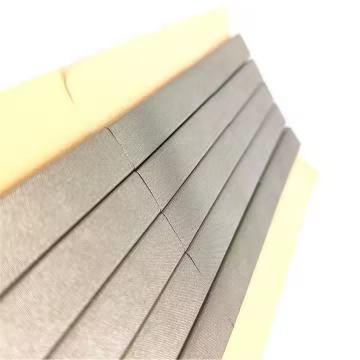

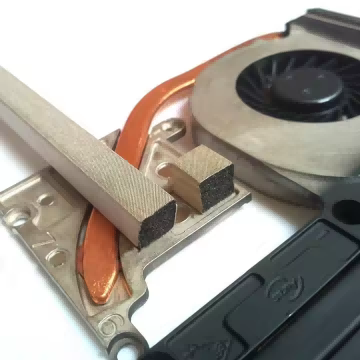

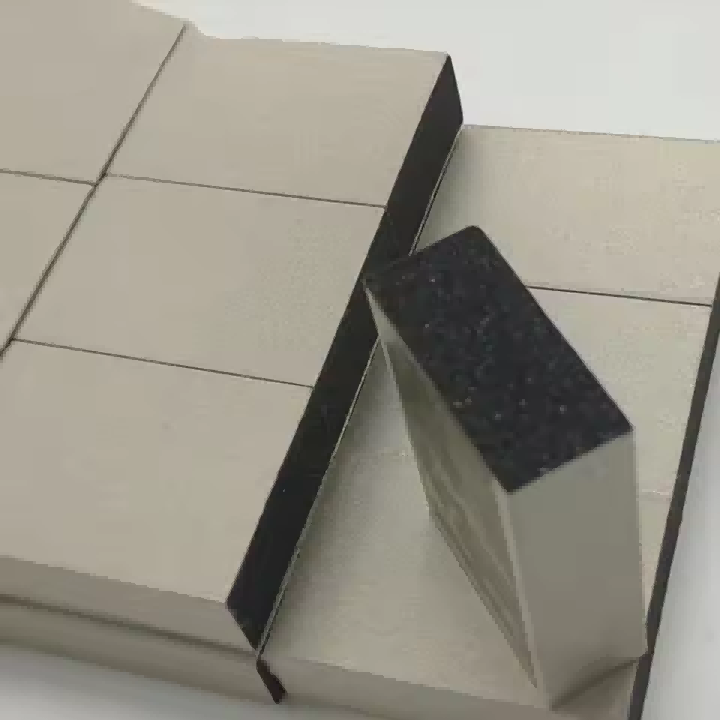

- Core Material: FUBA Foam: The core material of high-temperature resistant EMI gaskets is typically FUBA foam, a specialized semi-closed-cell EPDM (Ethylene Propylene Diene Monomer) foam. EPDM foam is chosen for its excellent sealing capabilities, flexibility, and resistance to a wide range of environmental factors. The semi-closed-cell structure of FUBA foam combines the flexibility of open-cell foams with the superior sealing properties of closed-cell foams, making it ideal for use in applications requiring both sealing and shielding.

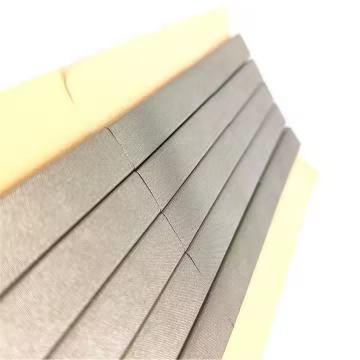

- Conductive Metallized Fabric: To achieve electromagnetic shielding, the FUBA foam core is covered with a conductive metallized fabric. This fabric is typically made from materials such as copper or aluminum, which are known for their excellent conductivity and ability to block electromagnetic interference. The metallized fabric forms an effective barrier against electromagnetic radiation, ensuring that the gasket performs its primary function of shielding sensitive electronic components from interference.

- Advanced Adhesive Technology: The foam core and conductive fabric are bonded using advanced adhesive technologies. These adhesives are carefully selected for their ability to withstand extreme temperatures while providing a strong and durable bond. This ensures that the gasket maintains its structural integrity and shielding effectiveness, even in challenging conditions.

Application Areas

High-temperature resistant EMI gaskets are used in a wide range of industries, where their ability to withstand high temperatures while providing reliable electromagnetic shielding makes them indispensable. Some key application areas include:

- Automotive Sector: In the automotive industry, high-temperature resistant EMI gaskets are employed for sealing HVAC units, dashboards, air ducts, glass runs, and firewalls. These gaskets help protect sensitive electrical components from electromagnetic interference, ensuring the proper functioning of modern automotive electronics.

- Building and Construction: In the building and construction sector, these gaskets are used to seal exterior panel joints, solar panels, and other structural components. They provide protection against both electromagnetic interference and environmental factors, improving the durability and performance of building systems.

- Industrial Applications: High-temperature resistant EMI gaskets are commonly used to seal air conditioners, mobile phones, refrigerators, and other electronic equipment. In these applications, they prevent the ingress of electromagnetic interference while ensuring thermal protection for the components inside.

- Other Uses: These gaskets are also employed in various industrial settings where high temperature resistance and electromagnetic shielding are required, such as in aerospace, telecommunications, and heavy machinery.

Key Specifications

The performance of high-temperature resistant EMI gaskets is determined by several important specifications. These specifications help define the gasket’s suitability for various applications:

- Temperature Service Range: Typically, high-temperature resistant EMI gaskets operate within a temperature range of -40°C to 135°C. Some formulations can tolerate even higher temperatures, making them suitable for use in extreme environments.

- Compression Load: The typical compression load at 50% compression is around 5 kPa. This value ensures that the gasket provides an effective seal without causing undue stress on the surrounding components.

- Elongation: High-temperature resistant EMI gaskets can stretch up to 430% of their original length, allowing them to conform to various surface shapes and accommodate structural movement.

- Tensile Strength: The tensile strength of these gaskets is typically around 90 kPa, ensuring that the gasket maintains its integrity under mechanical stress.

- Water Absorption: These gaskets meet ISO 2896 standards for water absorption, ensuring that they remain effective even in humid or wet environments.

- Flammability: High-temperature resistant EMI gaskets pass FMVSS 302 tests, ensuring that they meet stringent fire safety standards.

- Weatherability: The gaskets exhibit excellent resistance to environmental factors such as UV radiation, humidity, and temperature fluctuations, ensuring long-term durability.

- Deflection Capability: These gaskets can withstand up to 65% deflection, maintaining their sealing performance even under pressure or when subjected to structural movement.

Manufacturing Process

The production of high-temperature resistant EMI gaskets involves several critical steps to ensure that the final product meets all performance standards:

- Material Selection: The first step in the manufacturing process is the careful selection of materials, including FUBA foam and conductive metallized fabric. The materials must be chosen for their ability to withstand high temperatures and provide reliable electromagnetic shielding.

- Cutting and Shaping: The raw materials are then cut and shaped to the desired size and configuration. This process may involve precision cutting techniques to ensure that the gaskets fit the specific requirements of the application.

- Assembly: The foam core is laminated with the conductive metallized fabric using advanced adhesive technologies. This step ensures that the gasket provides both effective sealing and electromagnetic shielding.

- Quality Control: Rigorous testing is conducted to ensure that the gaskets meet the specified performance standards. This may include testing for temperature resistance, electromagnetic shielding effectiveness, compression load, and other key parameters.

- Packaging: Finally, the gaskets are packaged to protect them during transportation and storage. Proper packaging ensures that the gaskets remain in pristine condition until they are ready for installation.

Best Practices for Installation and Maintenance

To ensure optimal performance and longevity, high-temperature resistant EMI gaskets should be installed and maintained according to best practices:

- Proper Compression: To activate the gasket’s sealing properties, it should be compressed between 50-80%. Excessive compression can damage the gasket, while insufficient compression may result in an inadequate seal.

- Regular Inspection: Periodic inspection of the gaskets is essential to identify any signs of damage, wear, or degradation. Early detection of issues can help prevent system failures.

- Maintenance: Regular cleaning of the gasket surfaces helps maintain proper contact and sealing. Care should be taken to avoid contaminants that may affect the gasket’s performance.

- Temperature Monitoring: The operating temperature of the gasket should be monitored to ensure it remains within the specified range. Excessive temperatures may compromise the gasket’s performance and lead to premature failure.

- Documentation: It’s important to maintain detailed records of gasket installation, maintenance, and any repairs or replacements. This ensures traceability and helps in future troubleshooting efforts.

Comparison with Other Types of EMI Gaskets

High-temperature resistant EMI gaskets are often compared to other types of EMI gaskets based on their material composition, performance, and suitability for specific applications. Here’s how they stack up:

- Conductive Rubber/Silicone Gaskets: These gaskets are typically thinner and more rigid, making them suitable for lower-temperature applications. While they provide effective electromagnetic shielding, they may not offer the same level of heat resistance as high-temperature resistant gaskets.

- Combination Gaskets: These gaskets are thicker and softer, designed for larger enclosures or applications with limited clamping forces. They may provide excellent sealing properties but are less effective in shielding high levels of electromagnetic interference compared to high-temperature resistant gaskets.

- Foam-Based Gaskets: While foam-based gaskets are excellent for sealing, they may not provide the same level of electromagnetic shielding as conductive materials. High-temperature resistant EMI gaskets, with their combination of conductive metallized fabric and FUBA foam, offer both sealing and shielding advantages.

Challenges and Limitations

Despite their impressive capabilities, high-temperature resistant EMI gaskets do face certain challenges and limitations:

- Cost: These gaskets tend to be more expensive than standard EMI gaskets due to the specialized materials and manufacturing processes required. This can make them less cost-effective for some applications.

- Limited Availability: Not all manufacturers offer high-temperature resistant EMI gaskets, which may limit the range of options available to consumers and increase lead times.

- Specialized Knowledge: Proper installation and maintenance of high-temperature resistant EMI gaskets require a good understanding of electromagnetic principles and gasket behavior. Improper handling may compromise the gasket’s performance.

- Compatibility Issues: Ensuring that the gasket is compatible with other components in the system is crucial, particularly in high-temperature environments. Care must be taken to select the correct gasket formulation and configuration to avoid conflicts with adjacent materials.

Future Trends and Developments

As technology continues to evolve, we can expect several advancements in high-temperature resistant EMI gaskets:

- Improved Materials: Ongoing research into new materials with enhanced temperature resistance and electromagnetic shielding properties is likely to lead to the development of more advanced gasket formulations. This could improve gasket performance and expand their application range.

- Smart Gaskets: The integration of sensors or smart technologies into high-temperature resistant EMI gaskets may allow for real-time monitoring of gasket performance, providing early warnings of potential failures or degradation.

- Customization: As industries increasingly demand tailored solutions, there is likely to be a greater emphasis on customized gaskets designed to meet specific performance requirements for unique applications.

- Sustainability: With growing environmental concerns, there is a trend toward using recyclable and environmentally friendly materials in gasket production. This may lead to more sustainable manufacturing practices in the future.

Conclusion

High-temperature resistant EMI gaskets represent a significant advancement in electromagnetic shielding technology. Their ability to provide effective shielding while withstanding extreme temperatures makes them invaluable in numerous industrial and technological applications. As the demand for electromagnetic compatibility continues to grow, these specialized gaskets are likely to play an increasingly important role in maintaining the integrity of electronic systems in challenging environments.

By understanding their construction, specifications, and best practices for use, engineers and technicians can leverage the full potential of high-temperature resistant EMI gaskets to ensure the reliability and performance of complex systems operating in demanding conditions.

You May Also Like

-

High temperature resistant EMI gaskets with long-lasting performance

High temperature resistant EMI gaskets with long-lasting performanceShielding Gasket Solutions and Materials

High temperature resistant EMI gasket

High temperature resistant EMI gasket-Handa Shielding Introduction to High Temperature Resistant EMI GasketsKey Features of High Temperature Resistant EMI GasketsConstruction and MaterialsCore Material: FUBA FoamConductive Metallized FabricAdhesive TechnologyApplications of High Temperature Resistant EMI GasketsKey SpecificationsManufacturing ProcessBest Practices for Installation and......

-

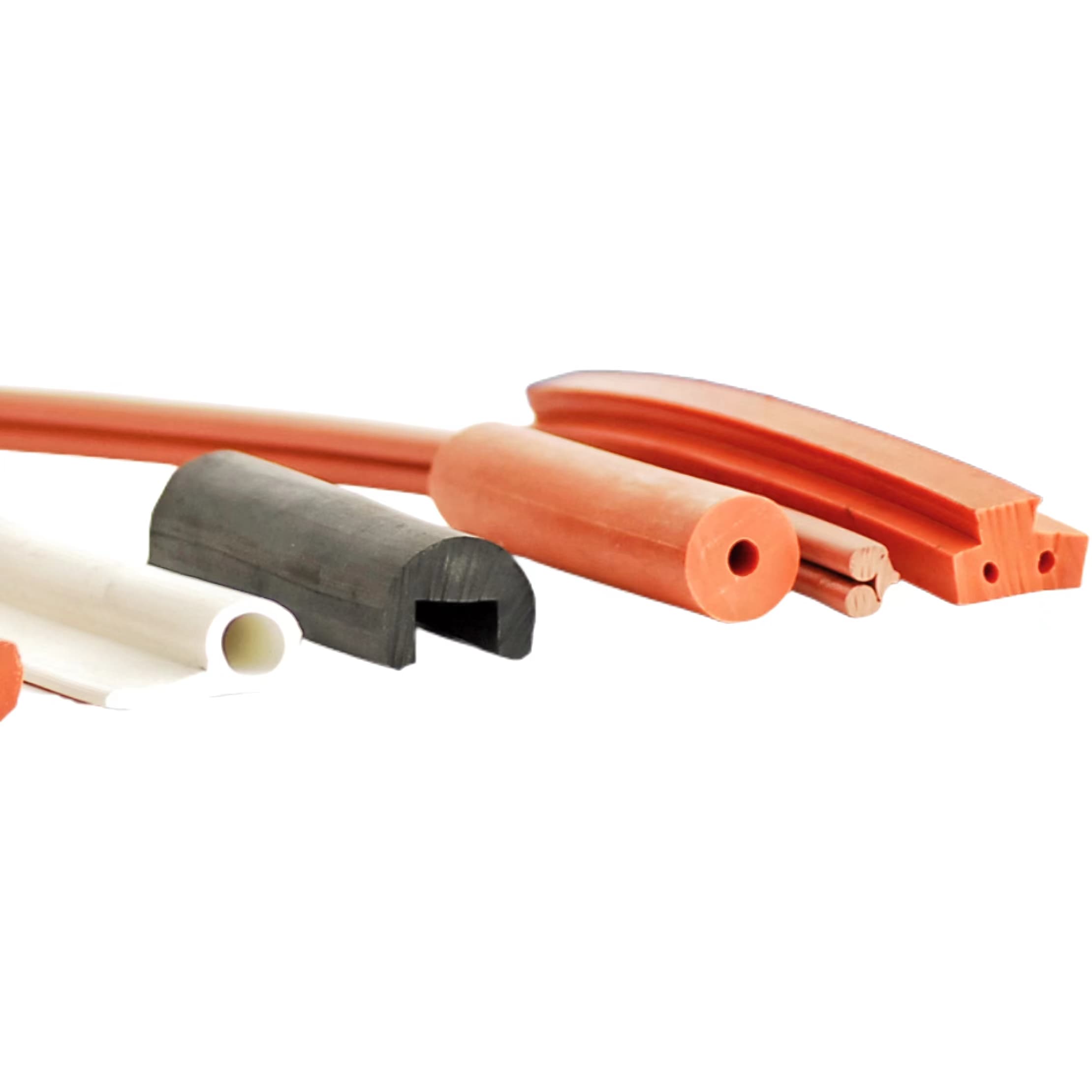

Electrically Conductive Rubber Profiles with Conductive Properties

Electrically Conductive Rubber Profiles with Conductive PropertiesShielding Gasket Solutions and Materials

Electrically conductive rubber profiles

Electrically conductive rubber profiles 1. Introduction to Electrically Conductive Rubber Profiles2. Key Components of Electrically Conductive Rubber Profiles2.1. Base Rubber Material2.2. Conductive Fillers2.3. Additives and Fillers for Mechanical Properties3. Manufacturing Process of Electrically Conductive Rubber Profiles3.1. Compounding3.2. Shaping3.3. Curing (Vulcanization)3.4.......

-

Flexible and Conductive Twisted Mounting Shielding Fingerstrips

Flexible and Conductive Twisted Mounting Shielding FingerstripsEMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

Twisted mounting shielding fingerstrips IntroductionWhat are Twisted Mounting Shielding Fingerstrips?Key Features1. Twisted Design for Maximum Flexibility2. Exceptional Electrical Conductivity3. Durable and Resilient Construction4. Compact and Space-Saving Profile5. Ease of InstallationMaterials and CoatingsBase MaterialsPlating OptionsBenefits of Twisted Mounting Shielding Fingerstrips1. Effective......

-

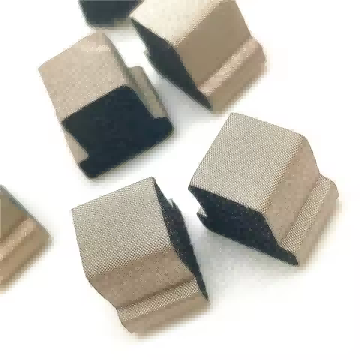

Handa Ultra Quick-Shield tin-plated stainless steel shielding gasket

Handa Ultra Quick-Shield tin-plated stainless steel shielding gasketEMI/EMC Shielding | RFI Shielding | EMI Gaskets

RF/EMI Shield Spiral Gasket

Handa Ultra Quick-Shield tin-plated stainless steel shielding gasket Introduction to EMI Shielding and Its ImportanceWhat Is the Handa Ultra Quick-Shield?Key Features of the Handa Ultra Quick-ShieldBenefits of Tin-Plated Stainless Steel Shielding Gaskets1. Enhanced Shielding Performance2. Corrosion and Wear Resistance3. Resilience......

-

Electrical conducting canted coil springs in high-voltage switchgear applications

Electrical conducting canted coil springs in high-voltage switchgear applicationsHanda Canted Coil Springs

Electrical conducting springs

Electrical conducting canted coil springs Abstract1. Introduction2. Structural Characteristics of Electrical Conducting Canted Coil Springs2.1 Simplicity and Compact Design2.2 Multiple Contact Points for Enhanced Conductivity2.3 Deformation Adaptability3. Material Selection for Electrical Conducting Canted Coil Springs3.1 Common Materials Used in Spring......