Glass Fiber Aluminum Foil Tape

Handa’s Glass Fiber Aluminum Foil Tape is an advanced composite tape designed for dual functionality: electromagnetic shielding and thermal insulation.

Engineered by bonding high-purity aluminum foil with flame-retardant glass fiber cloth and backed by a pressure-sensitive adhesive, this tape offers outstanding durability, temperature resistance, and shielding effectiveness in harsh environments.

Custom Manufacturing

Custom Handa’s Glass Fiber Aluminum Foil Tape

To customize your Glass Fiber Aluminum Foil Tape, contact our sales team(qinjunchang@handashielding.com)for a personalized quote and further assistance.

-

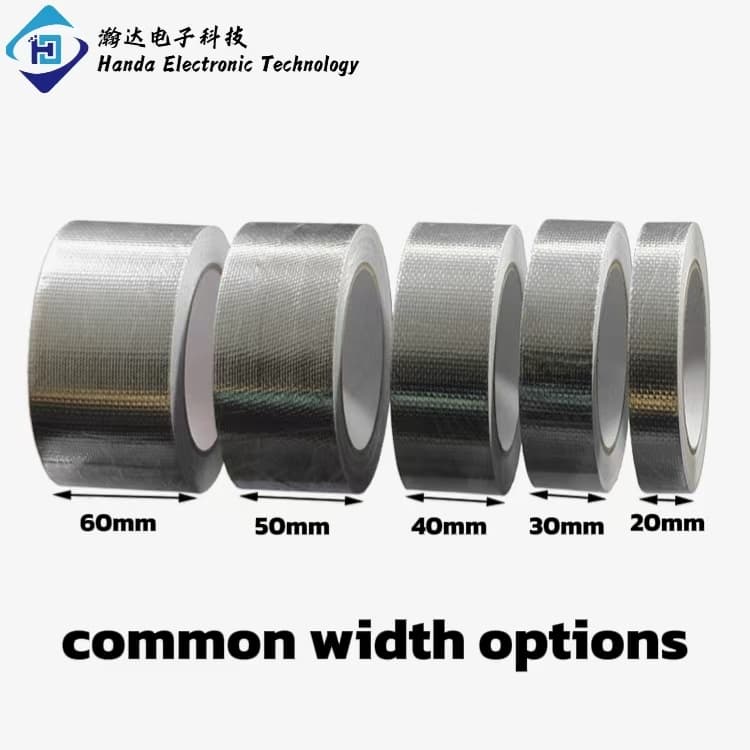

Size & Format: Custom widths (10–1,200 mm), lengths, cores (1″–3″), and scissors slits.

-

Adhesive Type: Acrylic, silicone, or rubber adhesives tailored to temperature and adhesion needs.

-

Release Liners & Labels: PET/PVC liners, private-label printing, barcoding.

-

Packaging: Options include bulk rolls, cut-to-length, sealed bags, export cartons.

Product descriptions

Specification

Handa’s Glass Fiber Aluminum Foil Tape is engineered for high-performance thermal insulation, flame resistance, and EMI shielding. The following table outlines our standard specifications—custom sizes, adhesives, and roll formats are available to meet your specific application needs.

|

item

|

value

|

|

Model Number

|

Glass Fiber Aluminum Foil Tape

|

|

Adhesive

|

Acrylic / Silicone

|

|

Adhesive Side

|

Single Sided

|

|

Material

|

Aluminum Foil + Fiberglass Cloth

|

|

Feature

|

Heat Resistant, Thermal Insulation, Flame Retardant, EMI Shielding

|

|

Color

|

Silver

|

|

Carrier

|

Aluminum Foil + Fiberglass

|

|

Adhesive Type

|

Conductive or Non-Conductive

|

|

Carrier Thickness (mm)

|

0.025–0.08

|

|

Total Thickness (mm)

|

0.06–0.15

|

|

Resistance (Ω)

|

≤0.3

|

|

Initial Tack (kg/inch)

|

≥1.0

|

|

Application Temperature (℃)

|

-40 to 150℃

|

|

Shielding Effectiveness (dB)

|

50–85

|

|

Width (mm)

|

10–1200 (Custom Slit)

|

Manufacturing Process of Handa’s

Glass Fiber Aluminum Foil Tape

At Handa, we follow a rigorous ISO 9001–certified process to ensure consistency, quality, and compliance for every batch.

1.Material Selection

-

Premium fiberglass fabric selected by weave density (e.g. 18×12, 20×20)

-

High-purity aluminum foil with thickness from 18–50 µm

-

Adhesives chosen based on thermal class (acrylic, silicone, hot melt)

2.Lamination Process

-

Aluminum foil and fiberglass are bonded using high-pressure thermal lamination

-

Ensures no air bubbles, curling, or separation in extreme conditions

3.Adhesive Coating

-

Adhesive applied via precision coating lines in controlled cleanroom environments

-

Ensures uniform coating weight and peel strength

4.Slitting & Rewinding

-

Tapes slit to width tolerances ±0.2 mm using high-precision cutters

-

Can be provided in roll, sheet, die-cut, or tape-on-liner format

5.Liner Application & Packaging

-

Silicone paper or PET liners applied if requested

-

Branded labels, barcodes, bulk packaging available

6.Inspection & QC

-

100% visual and sample testing for adhesion, tensile strength, thickness, release value

-

Optional tests: thermal aging, flame resistance, conductivity

Key Features & Benefits:

-

Durable Construction – Reinforced with fiberglass for tear and heat resistance.

-

High Heat Reflection – Withstands up to 250 °C (peak 500 °C); excellent thermal insulation.

-

Strong Adhesion – Acrylic or silicone adhesive bonds to various surfaces.

-

Weather & Flame Resistant – Performs in moisture, UV, and meets UL 723, BS476 standards.

-

Customizable – Available in various widths, thicknesses, liners, and packaging.

-

Optional EMI Shielding – Aluminum layer offers partial EMI protection when grounded.

Applications:

Applications of Conductive Aluminium Tape

-

HVAC & Ductwork: Sealing seams, vapor barriers, duct wraps.

-

Thermal & Flame Shielding: Heat wrap for cables, pipes, engine bays.

-

Aerospace & Defense: Harness protection, thermal masking, cable bundling.

-

Construction & Insulation: External barrier for rock/mineral wool and acoustic board.

-

Industrial Repairs: Temporary patching for tanks, pipes, high-temp surfaces.

❓ Frequently Asked Questions (FAQ)

-

Q1: What is the temperature resistance of your glass fiber aluminum foil tape?

A: Standard tapes operate from –50 °C to +250 °C. With silicone adhesive, peak short-term resistance reaches 500 °C. Custom solutions available.Q2: Does the tape block electromagnetic interference (EMI)?

A: The aluminum foil provides limited EMI shielding when properly grounded. For high-level EMI/RFI shielding, we recommend our Conductive Aluminum Tape or EMI Shielding Gaskets.Q3: Can I order the tape in custom widths and core sizes?

A: Absolutely. Widths from 10 mm to 1200 mm and roll cores of 1″, 1.5″, 2″, or 3″ are available. Slitting to narrow rolls or pads is supported.Q4: What is the shelf life and storage condition?

A: Shelf life is 12 months when stored at 20 °C and 50% RH in original packaging. Avoid sunlight, high heat, and high humidity.Q5: Is it safe for indoor air quality or sensitive environments?

A: Yes. Our adhesives are low-VOC, and tapes are RoHS, REACH, and halogen-free. Suitable for cleanrooms, electronics, and HVAC.

Need a Large Order?

-

Contact our Sales Team with:

-

Required width, length, thickness

-

Anticipated service temperature

-

Adhesive preference

-

Flame-rating needs (UL/BS/FAR)

-

Packaging/branding specifics

-

-

We’ll respond within 24 h with data sheets, quotes, and lead times.

RECENT PRODUCT

-

🔧 Product Overview📌 Key Features & Benefits⚙️ Technical Specifications🎯 Applications🛠 Customization Options📦 Packaging & Delivery🧩 Why Choose Handa?📞 Get a Quote or Sample......