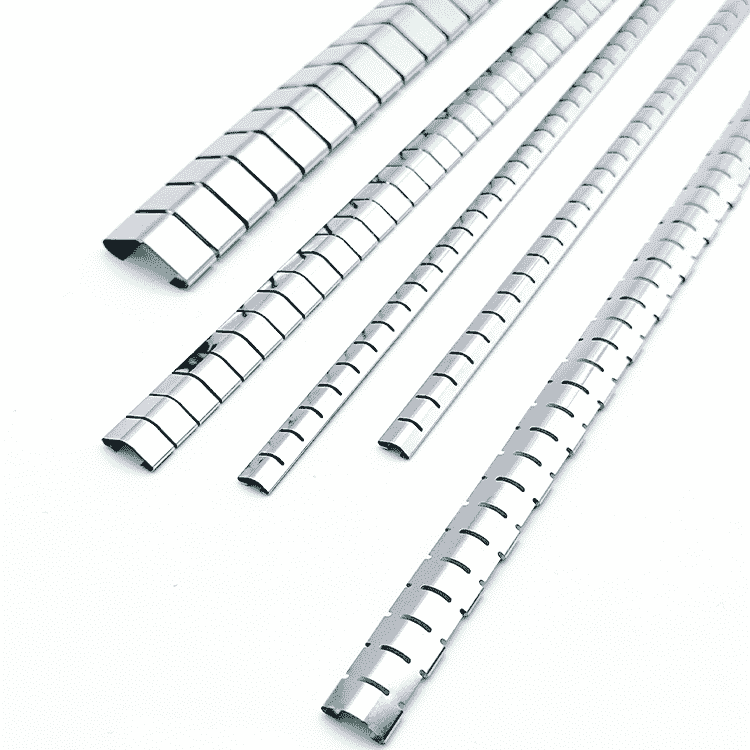

Electrically Conductive Rubber Profiles with Excellent Resilience, and Sealing Capabilities

Electrically conductive rubber profiles represent a unique intersection of material science and engineering, combining the flexibility and sealing properties of traditional rubber with the ability to conduct electricity. This makes them essential in various applications, particularly in sectors where electrical performance and mechanical reliability are critical. These specialized components are manufactured by incorporating conductive fillers, such as carbon black or metal particles, into rubber polymers.

Electrically conductive rubber profiles represent a unique intersection of material science and engineering, combining the flexibility and sealing properties of traditional rubber with the ability to conduct electricity. This makes them essential in various applications, particularly in sectors where electrical performance and mechanical reliability are critical. These specialized components are manufactured by incorporating conductive fillers, such as carbon black or metal particles, into rubber polymers. This article explores the features, benefits, applications, and manufacturing processes of electrically conductive rubber profiles, shedding light on their importance in modern industrial settings.

Table of Contents

Electrically Conductive Rubber Profiles

What Are Electrically Conductive Rubber Profiles?

Electrically conductive rubber profiles are rubber components engineered to facilitate the flow of electrical current while retaining the inherent advantages of rubber, such as flexibility, resilience, and sealing capabilities. They are particularly valuable in environments where both electrical and mechanical performance are paramount.

Composition and Materials

The primary materials used in electrically conductive rubber profiles include:

- Rubber Polymers: The base material that provides flexibility and durability. Commonly used types include natural rubber, silicone rubber, and neoprene.

- Conductive Fillers: These materials are mixed with the rubber polymers to impart electrical conductivity. Common fillers include:

- Carbon Black: A widely used filler that enhances conductivity while maintaining rubber properties.

- Metal Particles: Materials such as copper, aluminum, or silver can be used for higher conductivity levels.

Key Features and Benefits

1. Electrical Conductivity

One of the most significant features of electrically conductive rubber profiles is their ability to conduct electricity. This conductivity can be tailored to meet specific requirements, making these profiles suitable for various applications. The conductivity is achieved by carefully controlling the concentration and type of conductive fillers used in the rubber matrix.

2. Flexibility and Sealing Properties

Despite their electrical conductivity, these rubber profiles maintain the inherent flexibility and resilience characteristic of rubber materials. This makes them ideal for applications that require not only electrical functionality but also effective sealing against environmental factors such as dust, moisture, and chemicals.

3. Versatility

Electrically conductive rubber profiles can be designed for a broad range of industrial applications. Their adaptability allows them to be used in diverse sectors, including automotive, electronics, aerospace, and manufacturing.

Applications of Electrically Conductive Rubber Profiles

The versatility of electrically conductive rubber profiles allows for their use in numerous applications, including:

1. EMI/RFI Shielding

Electrically conductive rubber profiles are widely used for electromagnetic interference (EMI) and radio-frequency interference (RFI) shielding. They prevent the transmission of electromagnetic waves, protecting sensitive electronic components from interference that could disrupt their functionality. This shielding is essential in various electronic devices and systems, ensuring reliable operation.

2. Static Dissipation

These profiles also play a critical role in static dissipation, helping to dissipate static charges and prevent electrostatic discharge (ESD). ESD can damage electronic components, making electrically conductive rubber profiles vital in environments such as electronics manufacturing and assembly, where sensitive devices are handled.

3. Electrical Connectors and Contacts

Electrically conductive rubber profiles ensure reliable electrical connections in various applications. They provide a compliant interface that accommodates variations in mating surfaces, which is crucial for maintaining effective contact and minimizing resistance in electrical circuits. This feature is particularly valuable in automotive and industrial machinery.

4. Heating Elements

In some applications, electrically conductive rubber profiles serve as heating elements. When an electrical current passes through them, they generate heat, making them suitable for use in heated mats, automotive seat warmers, and medical devices. Their flexibility allows them to conform to various shapes, enhancing their usability in different products.

5. Industrial Equipment Seals

In industrial settings, electrically conductive rubber profiles can be used as seals for equipment, providing both sealing capabilities and electrical conductivity. This dual functionality is particularly advantageous in environments where equipment is exposed to harsh conditions, such as moisture or chemicals, while also requiring grounding or static control.

Manufacturing Process of Electrically Conductive Rubber Profiles

The production of electrically conductive rubber profiles involves several steps:

- Compounding: The first step is combining rubber polymers with conductive fillers. The specific formulation depends on the desired electrical properties and the application requirements. This process often involves mixing the rubber with the fillers in a controlled environment to ensure a uniform distribution.

- Molding or Extrusion: Once the compound is prepared, it is shaped into profiles using molding or extrusion techniques. In molding, the compound is placed in a mold and heated to cure the rubber, while extrusion involves forcing the compound through a die to create continuous profiles.

- Curing: The shaped rubber is cured to enhance its mechanical properties and set its shape. Curing can involve heat, pressure, or a combination of both, depending on the specific rubber formulation used.

- Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure that the final product meets the required specifications for electrical conductivity, mechanical strength, and other performance characteristics.

Conclusion

In conclusion, electrically conductive rubber profiles are an essential component in today’s industrial landscape, merging the advantages of rubber with the critical requirement for electrical conductivity. Their unique properties and versatility make them indispensable in applications that demand reliable sealing and electrical performance. As technology advances and industries expand, the significance of these profiles is set to increase, paving the way for innovative solutions that meet the complex demands of modern applications.

By understanding the features, benefits, and applications of electrically conductive rubber profiles, engineers and manufacturers can harness their potential to develop products that not only perform effectively but also contribute to the efficiency and reliability of various systems and devices.

You May Also Like

-

EMI shielding canted coil springs with unique canted coil design

EMI shielding canted coil springs with unique canted coil designHanda Canted Coil Springs

EMI Shielding Springs

EMI shielding canted coil springs, also known as canted coil springs, are innovative components designed to provide effective electromagnetic interference (EMI) and radio frequency interference (RFI) shielding while also serving as mechanical springs. These springs are characterized by their unique......

-

Multi-use Stick-on Mounting Fingerstrips with Excellent EMI Shielding Effect

EMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

Electromagnetic interference (EMI) can create significant issues for electronic devices and systems, leading to decreased performance, potential malfunction, or even failure. This is where stick-on mounting fingerstrips come in as an essential EMI shielding solution, especially for low-profile, bidirectional applications.......

-

High EMI Shielding Effect Snap-on mounting fingerstrips

High EMI Shielding Effect Snap-on mounting fingerstripsEMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

Snap-on mounting fingerstrips are highly effective Electromagnetic Interference (EMI) shielding components used in various electronic enclosures and assemblies to ensure electromagnetic integrity and prevent radio frequency interference (RFI). With the advancement of electronic systems, EMI shielding has become crucial to......

-

Highly Versatile and Indispensable Conductive Copper Foil Tape

Highly Versatile and Indispensable Conductive Copper Foil TapeEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Copper foil tape

Conductive copper foil tape is a highly versatile and indispensable material widely used in industries ranging from electronics to automotive. Its unique combination of electrical conductivity and adhesive properties allows it to serve as an efficient solution for various applications,......

-

Electrical Conductivity Aluminum Foil Tape

Electrical Conductivity Aluminum Foil TapeEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Conductive aluminium tape

Electrical conductivity aluminum foil tape is a versatile and essential material in various industries, particularly in electronics, electrical engineering, and construction. This article delves deep into the properties, applications, benefits, and selection criteria for electrical conductivity aluminum foil tape, focusing......