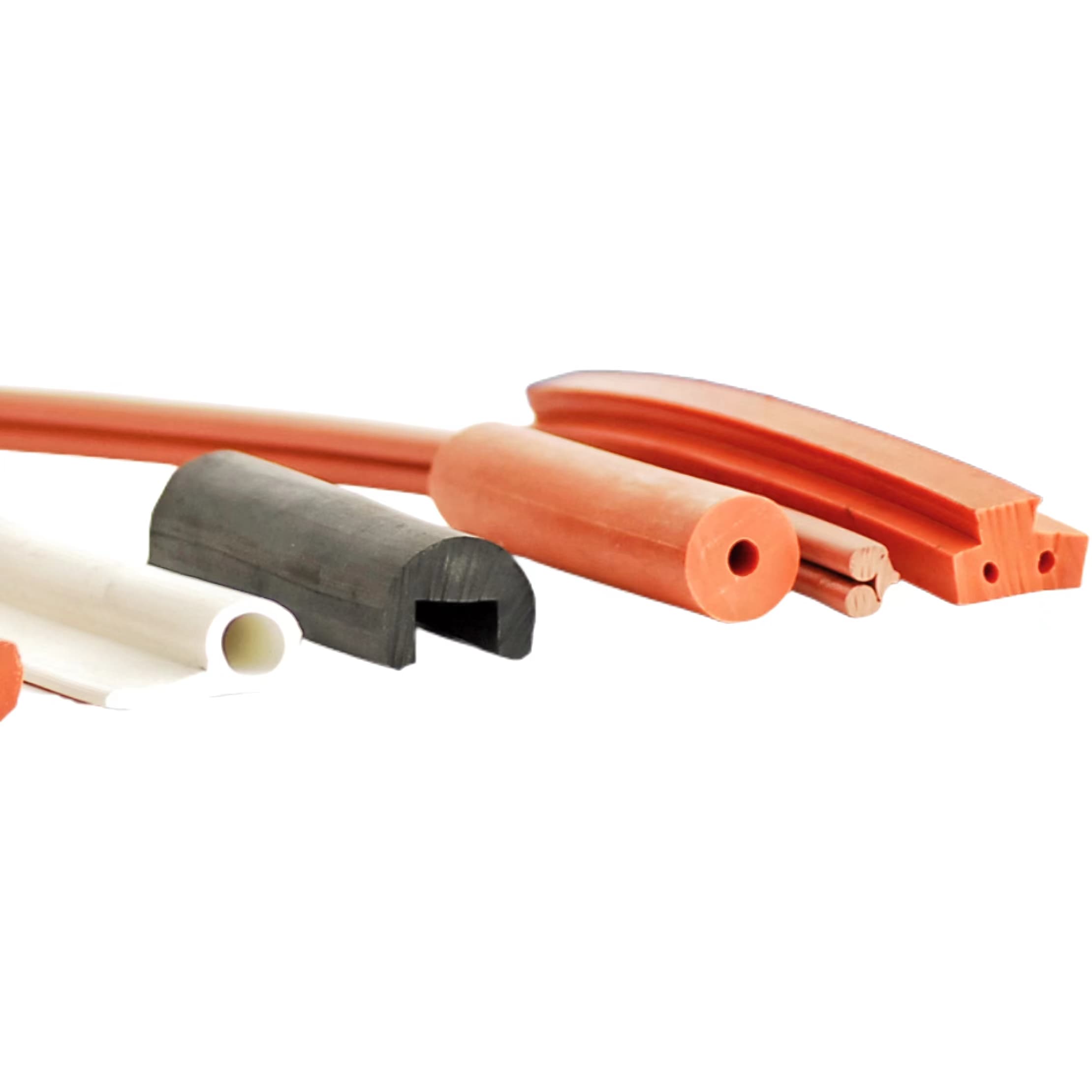

Electrically conductive rubber profiles

Handa Electrically conductive rubber profiles are specialized elastomeric components designed to combine the mechanical flexibility and resilience of rubber with the ability to conduct electricity. These profiles play a crucial role in various industries, particularly where electromagnetic interference (EMI) shielding, environmental sealing, and electrical continuity are essential.

Custom Manufacturing

Custom Electrically conductive rubber profiles

Electrically conductive rubber profiles are typically used for EMI applications. Also used for EMP protection, wave-guide applications and against static electricity. The rubber can be filled with silver, nickel, silvered glass, silvered aluminium or graphite (only for ESD). Commercial EMI applications often call for Nickel-Graphite Conductive Rubber Or Graphite Conductive Rubber due to costs, whereas military and aerospace applications often call for Silver Aluminium Silicone Conductive Rubber to meet Mil-G-83528C specifications. In military or aerospace, fluorosilicone versions may also be used for its chemical and fuel resistance.

If necessary, please contact sunny@handashielding.com and a professional engineer will answer your questions. Thank you!

Electrically conductive rubber profiles Manufacturing

Electrically conductive rubber profiles are specialized components used in a variety of applications requiring electromagnetic interference (EMI) shielding, electrical conductivity and environmental sealing. The manufacturing process of these profiles involves several steps:

1.Raw material preparation:

Select suitable raw rubber (e.g. silicone rubber, neoprene rubber, etc.) which have good dielectric constant.

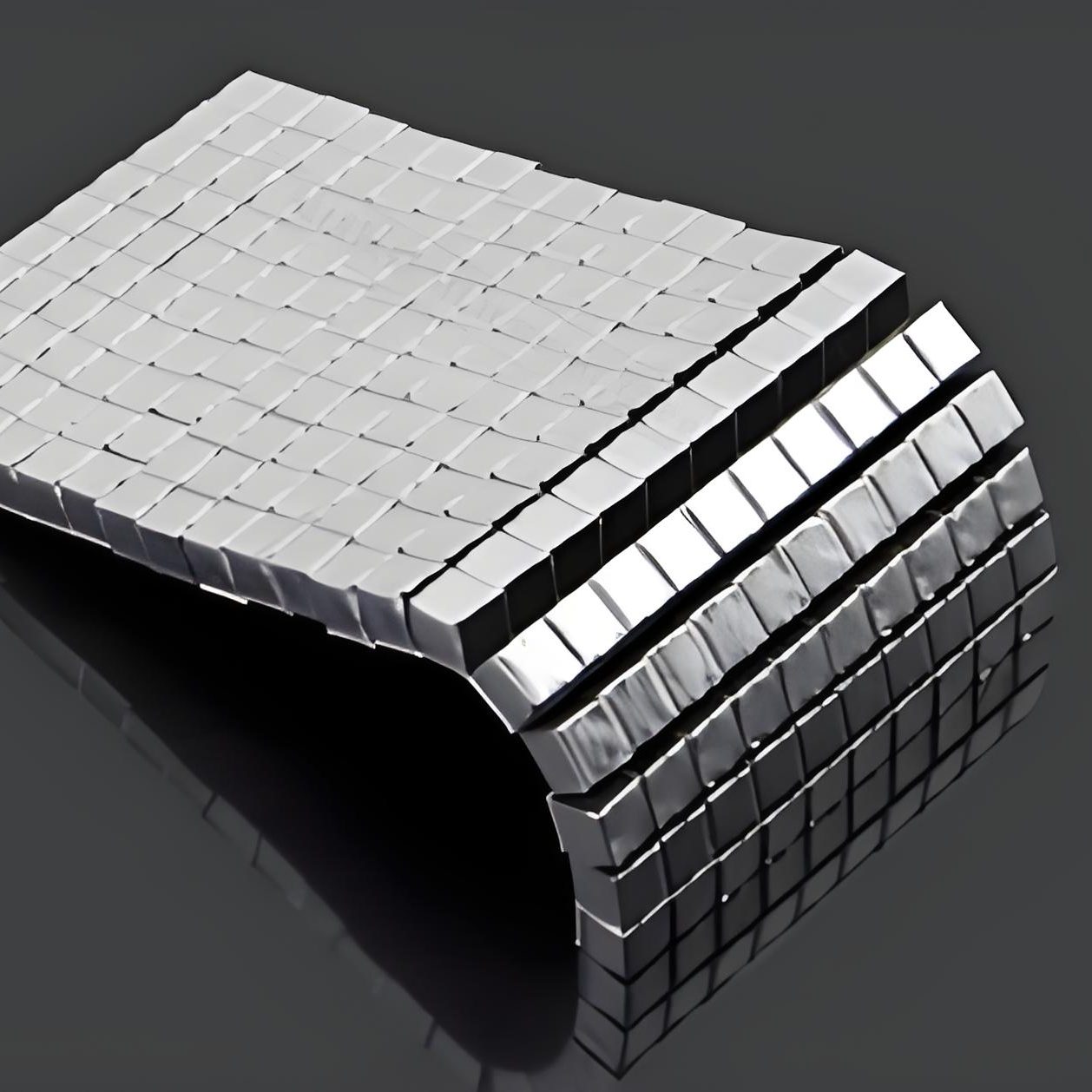

Prepare conductive fillers, such as carbon black, carbon fiber, metal powder or silver-plated glass beads.

2.Mixing and stirring:

Mix the raw rubber with appropriate amount of softener, vulcanizing agent, stabilizer and other additives.

Add conductive fillers to ensure uniform dispersion. This step is critical because the distribution of the filler directly affects the conductivity of the final product.

3.Add conductive filler:

Accurately measure the amount of conductive filler according to the formulation requirements, usually a critical value needs to be reached to form a conductive network.

4.Grinding adjustment:

Further grinding or blending of the mixture to ensure good contact between filler particles and to improve conductivity.

5. Molding:

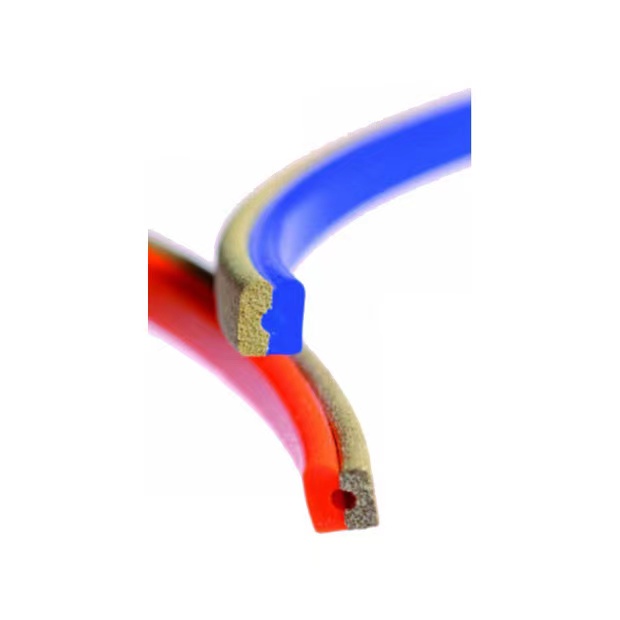

Molding or extruding the well-mixed rubber compound into the desired shape, such as an O-ring, sheet or specific seal.

6.Vulcanizing:

Curing and shaping of rubber by heating to cause a vulcanization reaction, ensuring its physical and mechanical properties and electrical conductivity.

Special material (on request)

These Conductive Rubber Profiles are also available in special materials for special applications, for example applications with chemicals. Below is a list of special materials. For availability and delivery please email sunny@handashielding.com

Silicone Carbon

Silicone Silver Aluminium

Silver Plated Nickel

Fluorosilicone Nickel Graphite

Fluorosilicone Silver Aluminium

Silver Glass

Silicone Nickel Graphite Flame Retardant

Fluorosilicone Nickel

Silver copper silicone conductive rubber

Application

Electrically conductive rubber profiles have a wide range of applications across various industries due to their unique combination of flexibility, sealing capabilities, and electrical conductivity. Here are some key applications:

Military Electronics: High-performance shielding for defense equipment where reliability is paramount.

Telecommunications: Protecting sensitive communication devices from EMI/RFI.

Aerospace: Used in avionics for reliable signal integrity and environmental sealing.

Medical Devices: Where EMI protection and biocompatibility are critical.

Automotive Electronics: Shielding in modern vehicles’ electronic systems from electromagnetic noise.

Consumer Electronics: In smartphones, laptops, and other devices for internal component protection.

Benefits

Electrically conductive rubber profiles offer several benefits that make them a preferred choice in various industries. These benefits include:

Effective EMI/RFI Shielding

Sealing and Environmental Protection

Electrical Continuity

Design Flexibility

Durability and Resistance

Ease of Installation

Flame Retardant Properties

Cost-Effective

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.

RECENT PRODUCT

-

Electrically conductive rubber profiles 1. Introduction to Electrically Conductive Rubber Profiles2. Key Components of Electrically Conductive Rubber Profiles2.1. Base Rubber Material2.2. Conductive Fillers2.3.......

-

Electrically conductive rubber profiles represent a unique intersection of material science and engineering, combining the flexibility and sealing properties of traditional rubber with......