Mechanische Verbindungsfedern

Handa Mechanische Verbindungsfeder ist eine der zuverlässigsten Lösungen für mechanische Verbindungsprobleme. Ihre geringe Größe, einfache Installation und Vielseitigkeit helfen Ihnen, die Komplexität und das Gewicht Ihrer mechanischen Systeme zu reduzieren und gleichzeitig deren Leistung zu verbessern.

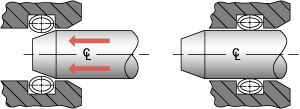

Die mechanische Verbindungsfeder verfügt über Einrast-, Sperr- und Haltefunktionen, lässt sich werkzeuglos installieren und ist robust genug, um Tausende von Einsteck- und Entnahmezyklen zu überstehen.

Wie man das Problem der mechanischen Verbindung löst

Die mechanischen Verbindungsfedern von Handa haben mehrere Funktionen, die verschiedene Probleme bei mechanischen Verbindungen lösen und die Leistung und Zuverlässigkeit des Systems verbessern können.

Dank seines flexiblen Designs und seiner präzisen Steuerungsmöglichkeiten ist er ideal für die Lösung komplexer mechanischer Verbindungsprobleme.

Verriegelung

Sichern Sie die beiden Gerätekomponenten zusammen und erleichtern Sie gleichzeitig die mehrfache Demontage und den Austausch

Verriegelung

Zwei Geräteteile sind fest miteinander verbunden und können nicht entfernt werden, ohne die Teile oder Federn zu beschädigen

Holding

Durch den Einsatz kontrollierter Federkräfte zum Halten und Ausrichten von Gerätekomponenten und zur Erleichterung der Gleitfunktion

Verriegelung & Schnellspanner

Verriegeln Sie die Komponenten des Geräts zusammen mit der Option, die Verriegelung vorzuschieben und zu umgehen, um sie mit geringem Kraftaufwand zu lösen

Produkt-Spezifikation

Empfohlene Produktgröße

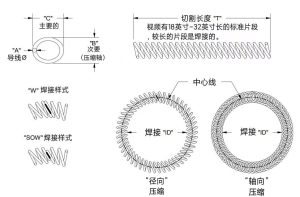

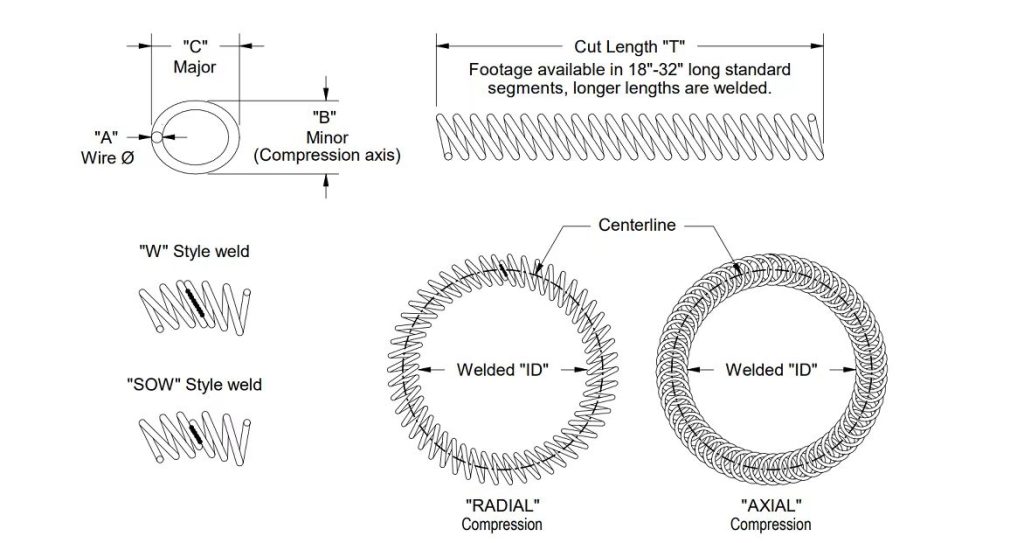

Oben sehen Sie die Maßzeichnung der mechanischen Verbindungsfeder, die entsprechend Ihren Anforderungen angepasst werden kann.

Oben sehen Sie die Maßzeichnung der mechanischen Verbindungsfeder, die entsprechend Ihren Anforderungen angepasst werden kann.

Sie können die passende mechanische Verbindungsfedergröße gemäß der Tabelle rechts auswählen

* Wir können den Materialdrahtdurchmesser und die Produkthöhe, die Breite und den Innendurchmesser entsprechend Ihren Anforderungen anpassen.

| SERIE | Art der Belastung | "A" (Drahtdurchmesser) |

"B" | "C" | "T" (Schnittlänge) |

"ID" (Geschweißte ID) |

|---|---|---|---|---|---|---|

| HD-CS-L132 | L | 0.08 | 0.62 | 0.70 | 7.60 | 1.80 |

| HD-CS-M132 | M | 0.10 | 0.62 | 0.70 | 7.60 | 1.80 |

| HD-CS-H132 | H | 0.12 | 0.65 | 0.75 | 7.70 | 1.80 |

| HD-CS-L000 | L | 0.12 | 1.40 | 1.55 | 12.90 | 2.70 |

| HD-CS-M000 | M | 0.15 | 1.40 | 1.55 | 12.90 | 2.70 |

| HD-CS-H000 | H | 0.20 | 1.20 | 1.32 | 12.20 | 2.70 |

| HD-CS-L100 | L | 0.18 | 2.00 | 2.40 | 19.80 | 4.30 |

| HD-CS-M100 | M | 0.35 | 2.00 | 2.40 | 20.10 | 4.40 |

| HD-CS-H100 | H | 0.35 | 2.00 | 2.30 | 19.80 | 4.30 |

| HD-CS-L200 | L | 0.30 | 2.80 | 3.20 | 30.10 | 6.80 |

| HD-CS-M200 | M | 0.35 | 2.80 | 3.20 | 30.10 | 6.80 |

| HD-CS-H200 | H | 0.40 | 2.80 | 3.20 | 30.10 | 6.80 |

| HD-CS-L300 | L | 0.40 | 4.00 | 4.50 | 42.70 | 9.60 |

| HD-CS-M300 | M | 0.50 | 4.00 | 4.50 | 42.70 | 9.60 |

| HD-CS-H300 | H | 0.60 | 4.00 | 4.50 | 42.70 | 9.60 |

| HD-CS-L400 | L | 0.50 | 5.50 | 6.00 | 61.20 | 14.00 |

| HD-CS-M400 | M | 0.60 | 5.50 | 6.00 | 61.20 | 14.00 |

| HD-CS-H400 | H | 0.70 | 5.50 | 6.00 | 61.20 | 14.00 |

| HD-CS-L500 | L | 0.60 | 8.20 | 9.20 | 96.40 | 22.50 |

| HD-CS-M500 | M | 0.70 | 8.20 | 9.20 | 96.40 | 22.50 |

| HD-CS-H500 | H | 1.00 | 8.20 | 9.20 | 96.40 | 22.50 |

| HD-CS-L600 | L | 0.70 | 11.40 | 12.80 | 152.00 | 37.00 |

| HD-CS-M600 | M | 1.00 | 11.40 | 12.80 | 152.00 | 37.00 |

| HD-CS-H600 | H | 1.20 | 11.40 | 12.80 | 152.00 | 37.00 |

Material und Beschichtung

Mechanische Verbindungsfedern von Handa sind in einer Vielzahl von Draht- und Oberflächenbehandlungen erhältlich, um spezifische Leistungsanforderungen zu erfüllen. Um die Möglichkeit der Korrosion zwischen verschiedenen Metallen zu verringern, können wir Federn durch Galvanisieren von Metallmaterialien herstellen. Die Wahl des Materials beeinflusst die Leistung der Feder und ihre Eignung für eine bestimmte Anwendung.

Rostfreier Stahl (304, 316, 316L)

BeCu(Beryllium-Kupfer)

BeCu(Beryllium-Kupfer)

Verzinnung

Vernickelung

Vergoldung

Versilberung

Kundenspezifische Fertigung

Kundenspezifische mechanische Verbindungsfedern

Je nach den Anforderungen des Kunden stellt Handa Shielding Zeichnungen oder Abmessungen und Anforderungen an die Arbeitsbedingungen für die Produktanpassung zur Verfügung. Falls erforderlich, kontaktieren Sie bitte sunny@handashielding.com und ein professioneller Ingenieur wird Ihre Fragen beantworten. Wir danken Ihnen!

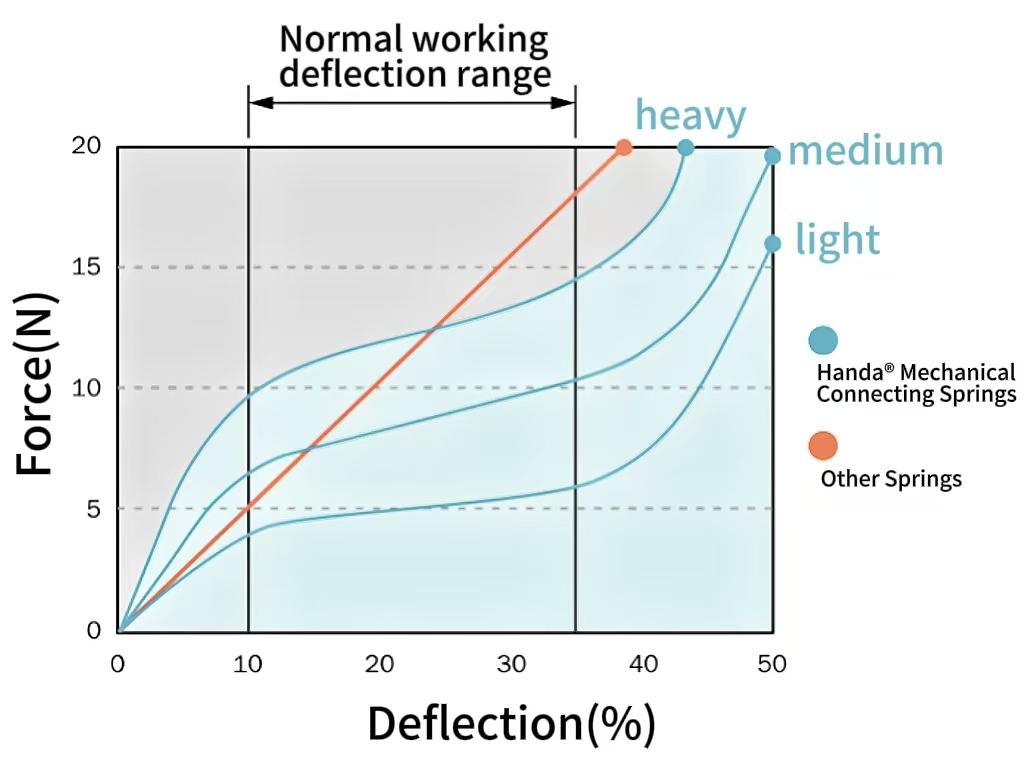

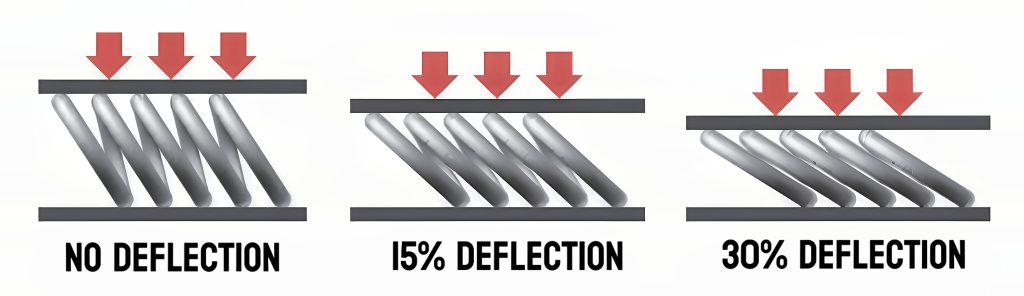

Druckkraftleistung einer mechanischen Verbindungsfeder

Bei Kompression weist die Feder eine einzigartige Einfederungs-Kraftcharakteristik auf. Im Gegensatz zu konventionellen Federn behalten unsere Federn eine nahezu konstante Kraft über den gesamten Betriebseinfederungsbereich bei, und diese Kraftcharakteristik bleibt über einen breiten Temperaturbereich stabil. Die Federkonstruktion ist in der Lage, einer Druckverformung zu widerstehen, und jede Windung kann sich gegenseitig kompensieren, um sich an Positionsabweichungen, Abmessungstoleranzen und Unregelmäßigkeiten der Anschlussfläche anzupassen. Durch die präzise Einstellung von Parametern wie Federschlitzen, Federabmessungen und Drahtdurchmessern können wir eine präzise Kraftsteuerung für Funktionen wie Einrasten, Verriegeln, Halten, Verbinden und Trennen erreichen.