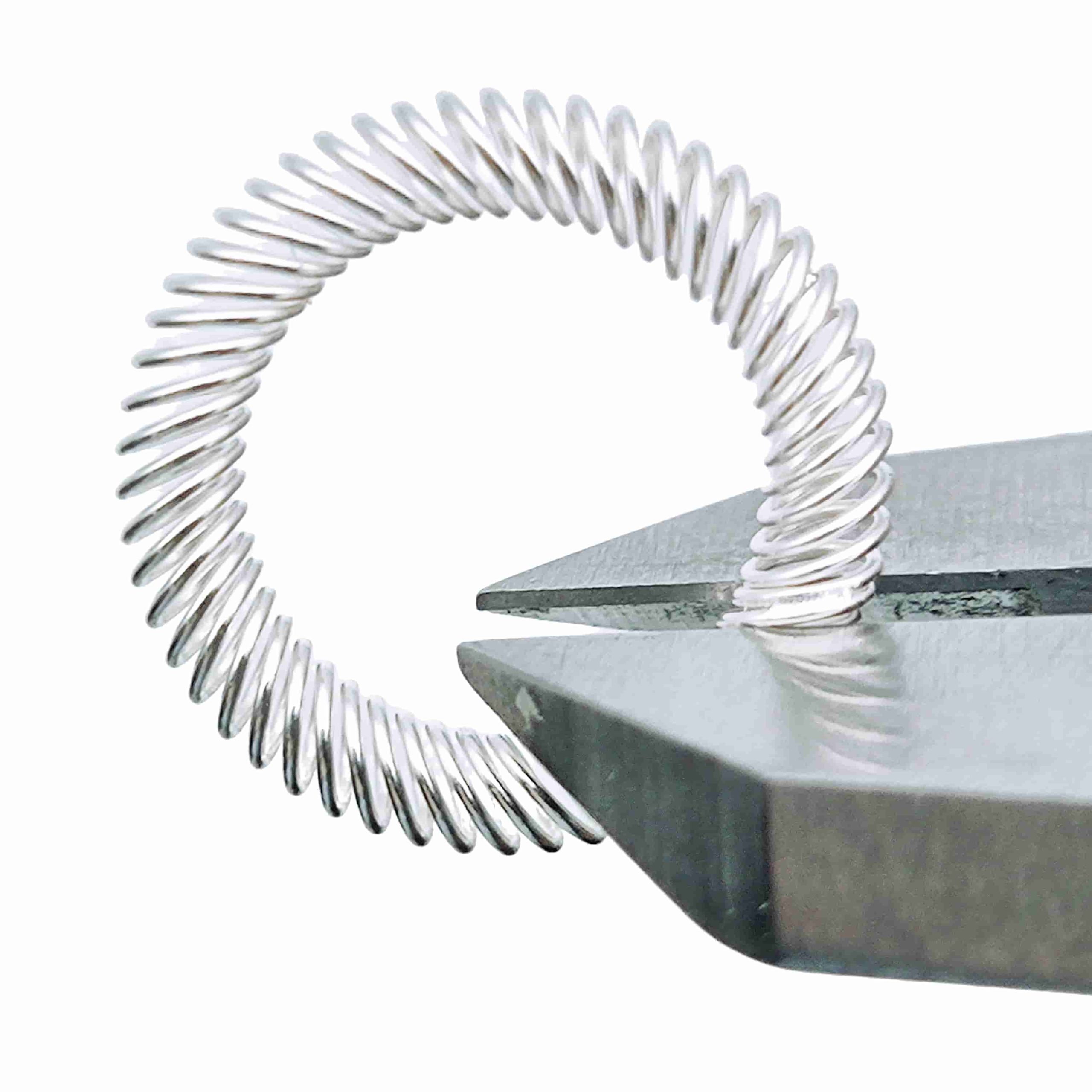

Custom Canted Coil Spring: Design Considerations and Manufacturing Process

Our custom canted coil springs are precision-engineered solutions designed to deliver consistent force, long service life, and reliable performance in demanding applications. Featuring uniquely angled coils, these springs provide near-constant load over a wide deflection range, making them ideal for applications where traditional compression springs fall short.

Each custom canted coil spring is designed specifically to meet your mechanical, electrical, and environmental requirements. By tailoring parameters such as wire diameter, coil angle, free height, and ring diameter, we ensure optimal force-deflection behavior and seamless integration into your assembly. Custom sizing allows compatibility with non-standard grooves, housings, and compact designs.

We offer a wide selection of high-performance materials, including stainless steel, beryllium copper, Elgiloy, Inconel, and Hastelloy. Material selection is based on operating conditions such as temperature, corrosion exposure, electrical conductivity, and fatigue requirements. Optional surface treatments and plating—such as silver, gold, or tin—are available to enhance conductivity, wear resistance, and environmental durability.

Our custom canted coil springs can be supplied as open coils or welded rings and are suitable for multiple functions, including mechanical retention, electrical contact, and EMI/RFI shielding. Advanced CNC coiling, controlled heat treatment, and rigorous inspection processes ensure consistent quality and repeatable performance.

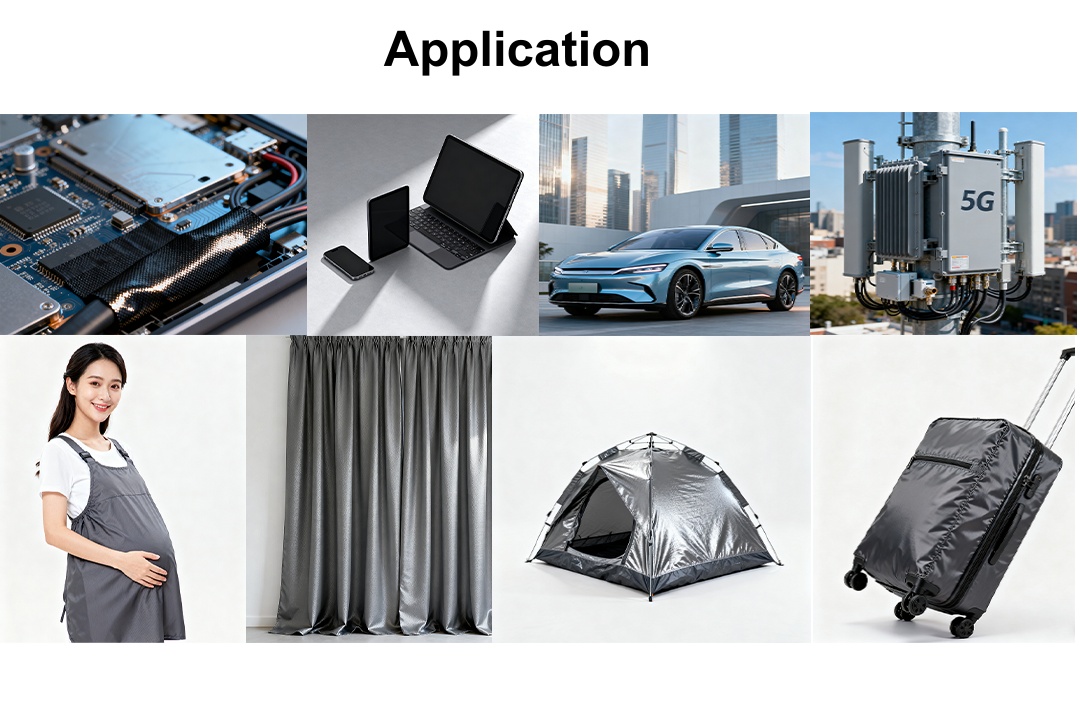

Whether used in electrical connectors, medical devices, semiconductor equipment, or aerospace systems, our custom canted coil spring solutions help reduce component count, simplify assembly, and improve overall system reliability.

Custom canted coil springs offer tailored force, deflection, and durability for demanding applications. Learn key design considerations, materials, manufacturing processes, and quality controls for custom canted coil spring solutions.

Introduction

In today’s high-performance mechanical and electrical systems, standard components often fall short of meeting precise functional requirements. This is especially true for springs used in critical applications such as electrical contacts, EMI shielding, latching mechanisms, and high-cycle connectors. As a result, custom canted coil spring solutions have become increasingly important across industries including aerospace, medical devices, semiconductor equipment, and industrial automation.

Unlike conventional compression or extension springs, canted coil springs feature uniquely angled coils that deliver nearly constant force over a wide deflection range. When combined with customization in geometry, material, and manufacturing methods, a custom canted coil spring can be engineered to solve complex design challenges while improving reliability and service life.

This article explores the key design considerations and manufacturing process behind custom canted coil springs, providing engineers and procurement teams with a comprehensive technical overview.

What Is a Custom Canted Coil Spring?

A canted coil spring is formed by winding wire into coils that are tilted (or “canted”) relative to the spring axis. This geometry allows the spring to compress smoothly while maintaining consistent load characteristics.

A custom canted coil spring is designed specifically for an application’s mechanical, electrical, and environmental requirements, rather than relying on standard off-the-shelf dimensions.

Key characteristics include:

- Near-constant force over long deflection

- Excellent fatigue resistance

- Compact radial and axial footprint

- Capability to perform multiple functions (contact, retention, shielding)

Customization ensures that the spring integrates seamlessly into its mating groove or housing while delivering predictable performance.

Why Choose a Custom Canted Coil Spring?

Standard springs are often designed with generalized assumptions. In contrast, a custom canted coil spring is engineered around real-world operating conditions.

Advantages of Customization

- Optimized force-deflection curve for precise engagement

- Improved durability in high-cycle or harsh environments

- Material compatibility with corrosion, temperature, or conductivity requirements

- Space efficiency, especially in compact or lightweight assemblies

For mission-critical systems, these advantages directly translate into improved system reliability and reduced maintenance costs.

Key Design Considerations for Custom Canted Coil Springs

Designing a custom canted coil spring requires a systematic evaluation of multiple parameters. Each variable influences the final performance and manufacturability of the spring.

1. Load and Deflection Requirements

The primary design input is the required force across a specific deflection range.

Important questions include:

- What is the minimum and maximum working load?

- Is constant force required or a progressive load acceptable?

- What is the allowable solid height and working stroke?

A custom canted coil spring can be tuned by adjusting coil angle, wire diameter, and pitch to meet these force-deflection targets.

2. Spring Geometry and Size

Space constraints often drive customization.

Key geometric parameters include:

- Inner diameter (ID) and outer diameter (OD)

- Free height or free length

- Coil angle and number of active coils

Custom sizing ensures compatibility with non-standard grooves, housings, or mating components.

3. Material Selection

Material choice is critical for both mechanical performance and environmental resistance. A custom canted coil spring can be manufactured from a wide range of alloys depending on application needs.

| Material | Key Properties | Typical Applications |

|---|---|---|

| Stainless Steel (302/304/316) | Corrosion resistance, good fatigue life | Industrial, medical |

| Beryllium Copper | High conductivity, good spring properties | Electrical contacts |

| Elgiloy / MP35N | High strength, corrosion resistance | Aerospace, oil & gas |

| Inconel / Hastelloy | High-temperature stability | Semiconductor, energy |

Selecting the right material allows the custom canted coil spring to maintain performance under thermal cycling, vibration, or corrosive exposure.

4. Environmental Conditions

A thorough environmental assessment is essential during the design phase.

Considerations include:

- Operating temperature range

- Exposure to chemicals, moisture, or salt fog

- Vibration and shock loads

For extreme environments, custom surface treatments or coatings may be applied to enhance corrosion resistance and wear life.

5. Functional Requirements

Many applications require the spring to perform more than one function.

A custom canted coil spring may serve as:

- A mechanical retention or locking element

- An electrical contact path

- An EMI/RFI shielding interface

Designing for multifunctionality can reduce part count and simplify assembly.

Manufacturing Process of Custom Canted Coil Springs

Once design parameters are finalized, the manufacturing process begins. Precision and consistency are essential to ensure performance repeatability.

Step 1: Wire Preparation

The selected wire material is drawn to a precise diameter and heat-treated as required. Surface finish and cleanliness are tightly controlled, especially for electrical or medical applications.

Step 2: Coil Forming

The wire is wound into canted coils using specialized CNC coiling equipment. Unlike conventional springs, the coil angle must be carefully controlled to achieve the desired load behavior.

For a custom canted coil spring, tooling is often adjusted specifically for the customer’s design.

Step 3: Heat Treatment

After forming, the spring undergoes stress relief or age-hardening heat treatment. This step stabilizes the microstructure and improves fatigue life.

Step 4: Ring Formation (Optional)

Depending on application requirements, springs may be supplied as:

- Open coils (non-welded lengths)

- Closed rings (welded or mechanically joined)

Ring formation ensures uniform load distribution in circular groove designs.

Step 5: Surface Treatment and Plating

Optional plating or coating may be applied, such as:

- Silver or gold plating for conductivity

- Tin plating for corrosion resistance

- Passivation for stainless steel springs

These treatments further tailor the custom canted coil spring to its operating environment.

Step 6: Inspection and Quality Control

Each custom canted coil spring is inspected for:

- Dimensional accuracy

- Load-deflection performance

- Surface integrity

Statistical process control (SPC) and 100% inspection may be used for critical applications.

Design vs. Manufacturing: Key Parameters Overview

The table below summarizes how design inputs translate into manufacturing controls:

| Design Parameter | Manufacturing Control | Impact on Performance |

|---|---|---|

| Wire diameter | Wire drawing tolerance | Load accuracy |

| Coil angle | CNC coiling setup | Force consistency |

| Material alloy | Heat treatment profile | Fatigue life |

| Ring diameter | Welding or joining precision | Fit and sealing |

This close link between design and manufacturing is what enables high-performance custom canted coil spring solutions.

Applications of Custom Canted Coil Springs

Because of their adaptability, custom canted coil springs are used in a wide range of industries:

- Electrical connectors requiring stable contact force

- EMI shielding interfaces in electronic enclosures

- Medical devices needing compact, reliable springs

- Aerospace mechanisms exposed to vibration and temperature extremes

Customization ensures optimal performance in each unique application.

Conclusion

A custom canted coil spring is far more than a simple mechanical component. Through careful consideration of load requirements, geometry, materials, and environment, engineers can design a spring that delivers consistent force, long service life, and multifunctional performance.

Equally important is a controlled manufacturing process that translates design intent into repeatable, high-quality products. From wire preparation to final inspection, every step contributes to the reliability of the final spring.

For applications where performance, durability, and precision matter, investing in a custom canted coil spring solution is a strategic decision that pays dividends over the life of the system.

For more info.,please email to : sale01@handashielding.com

You May Also Like

-

Loss of Force in Canted Coil Springs: Causes and Solutions

Loss of Force in Canted Coil Springs: Causes and SolutionsFingerstrips

Right-angle shielding fingerstrip

Loss of force in canted coil springs explained. Learn the root causes, performance impacts, and proven engineering solutions to ensure long-term spring reliability. Introduction Canted coil springs are widely recognized for their ability to deliver near-constant force over a wide......

-

Canted Coil Spring for EMI Shielding

Canted Coil Spring for EMI ShieldingRF/EMI Shield Spiral Gasket

Handa Spiral Shield

Canted coil spring for EMI shielding provide consistent contact force, superior conductivity, and long service life. Learn how they work, key advantages over fingerstock, material options, installation design, and typical EMI shielding applications. Canted Coil Spring for EMI Shielding Electromagnetic......

-

HANDA RF/EMI Shielding Hastelloy Spiral Gasket for Semiconductor CVD Equipment

HANDA RF/EMI Shielding Hastelloy Spiral Gasket for Semiconductor CVD EquipmentRF/EMI Shield Spiral Gasket

Handa Spiral Shield

Discover HANDA’s RF/EMI Shielding Spiral Gasket made from premium Hastelloy C-276. Engineered for semiconductor CVD equipment, it delivers exceptional chemical resistance, high-temperature stability, and reliable RF/EMI attenuation for demanding plasma and vacuum process environments. HANDA proudly introduces its latest high-performance......

-

HANDA Spiral EMI Shielding Gaskets Solutions Now Available

HANDA Spiral EMI Shielding Gaskets Solutions Now AvailableRF/EMI Shield Spiral Gasket

Handa Spiral Shield

Hunan Handa Spiral Spring EMI Shielding Solutions New Partnership Announcement: HANDA Spiral EMI Shielding Gaskets Solutions Now Available.As the demand for reliable electromagnetic interference (EMI) protection continues to grow across electronics, telecommunications, automotive, and aerospace industries, manufacturers are seeking shielding......

-

High-Performance Conductive Fabric for EMI Shielding in Electronics and Communication Equipment

High-Performance Conductive Fabric for EMI Shielding in Electronics and Communication EquipmentEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Conductive cloth/fabrics

1. Introduction to Conductive Fabric2. Key Performance Advantages3. Applications in Electronics and Communication3.1 Consumer and Industrial Electronics3.2 5G and Telecommunication Systems3.3 Automotive Electronics3.4 Aerospace and Defense3.5 Wearable and Medical Devices4. Technical Specifications5. Why Choose Handa Shielding7. Conclusion 1. Introduction to......