How Copper Foil Tape Is Made: Step-by-Step Manufacturing Process & Quality Insights

Copper foil tape plays a pivotal role in a myriad of industries—from electronics and shielding to renewable energy applications. Its exceptional conductivity, flexibility, and durability make it indispensable. Let’s take an in-depth look at how this versatile product is manufactured, ensuring peak performance every time.

Table of Contents

1. Copper Foil Production

a) Electrodeposition Process

- High-purity copper is dissolved in an electrolyte solution, commonly sulfuric acid–based.

- The solution undergoes electrolysis using a rotating titanium drum (cathode) and suitable anodes, depositing ultra-thin, uniform copper layers onto the drum.

- Foil thickness and surface quality (smooth drum side, matte reverse side) are regulated by controlling drum speed, current density, and electrolyte additives.

b) Rolling Method (Alternative Technique)

- Copper slabs are hot-rolled and cold-rolled with intermittent heat treatment (annealing) to achieve desired foil thickness and mechanical characteristics.

- Surface finishes—whether shiny, matte, or half-matte—are achieved during these steps.

2. Surface Treatment & Protection

- After basic forming, copper foil undergoes chemical and electrochemical treatments to enhance adhesion of adhesives and resist corrosion.

- Final protective coatings are applied to preserve foil integrity during storage and application.

3. Adhesive Lamination

- A conductive or non-conductive adhesive layer is applied, selected based on intended usage (e.g., EMI shielding versus general purpose).

- The application uses precision coating methods to ensure uniform coverage, followed by curing or drying.

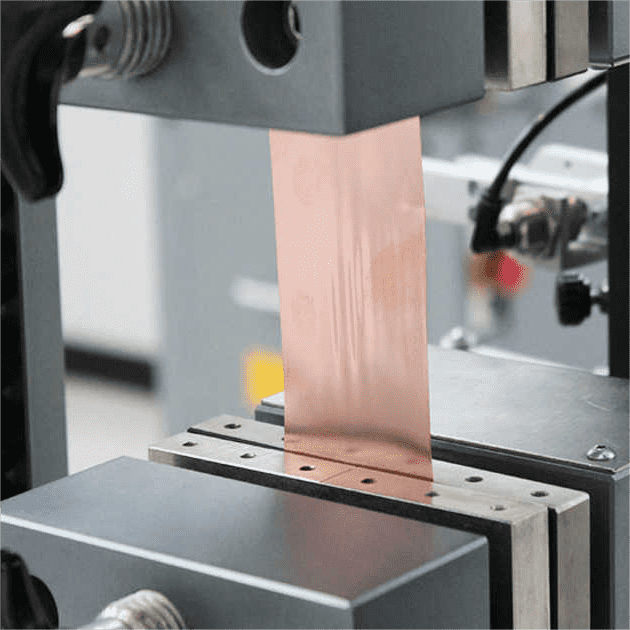

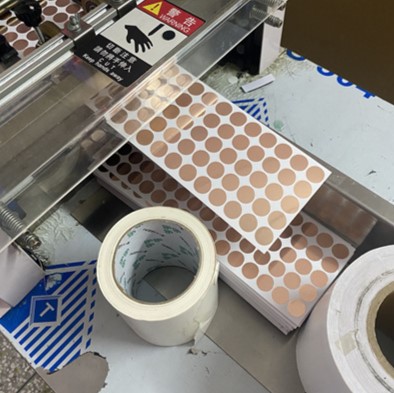

4. Cutting, Slitting & Packaging

- Laminated foil is slit to precise widths (e.g., roll widths or custom die-cut shapes), tailored to customer requirements.

- Final inspection ensures cleanliness and surface integrity before packaging to prevent oxidation and contamination.

5. Quality Control & Testing

- Rigorous QC spans all stages: incoming material checks, in-process dimensional and surface audits, and final conductivity and adhesion testing.

- Environmental resilience—like thermal cycling, humidity exposure, and corrosion resistance—is validated per industry standards (e.g., ISO 9001).

6. Advanced Innovations & Applications

- Emerging applications: In renewable energy (e.g., solar panels), copper foil tape is evolving with advances like graphene-enhanced conductivity, ultra-thin designs via atomic-layer deposition, and eco-friendly/nanocoatings.

Conclusion:

From melting and refining to coating, cutting, and quality assurance—every phase in the manufacturing process of copper foil tape is meticulously controlled. Whether via electrodeposition or rolling, manufacturers ensure optimal conductivity, adhesion, flexibility, and surface quality. Integrated surface treatments and adhesive lamination further enhance functionality across electronics, automotive, and green technologies.

In summary, copper foil tape is meticulously crafted through high-precision processes and standards. Understanding these steps empowers both manufacturers and customers to prioritize quality, efficiency, and innovation in applications that demand high-performance materials.