Освоение прокладок из вязаной проволочной сетки: От аэрокосмической промышленности до промышленного оборудования - все, что вам нужно знать

Прокладки из вязаной металлической сетки - Ханда Экранирование

Оглавление

В сложном ландшафте промышленных и технологических систем невозможно переоценить значение эффективной герметизации, экранирования электромагнитных помех (ЭМП) и виброизоляции. Эти функции являются стержнями, обеспечивающими бесперебойную работу, безопасность и долговечность широкого спектра оборудования, от высокотехнологичной электроники, питающей нашу повседневную жизнь, до колоссальных машин, обеспечивающих промышленное производство. Прокладки из вязаной проволочной сетки стали краеугольным решением, позволяющим удовлетворить эти важнейшие требования с поразительной эффективностью. Компания Handashielding находится на переднем крае производства и поставок продукции высшего уровня. прокладки из вязаной проволочной сеткиУдовлетворяя разнообразные потребности различных отраслей промышленности.

1. Обзор продукции

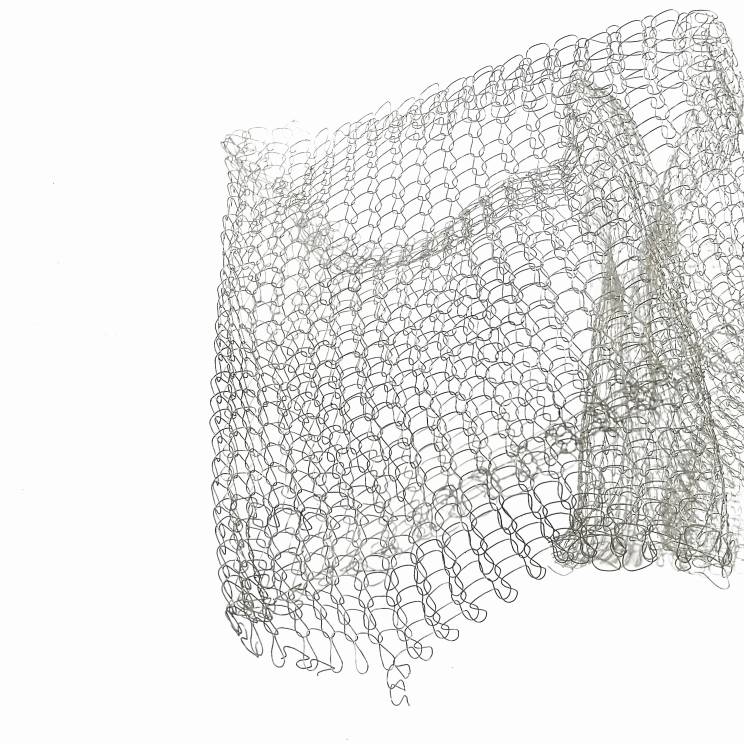

1.1 Строительство

Наши вязаные сетчатые прокладки тщательно изготавливаются с использованием высококачественной металлической проволоки. Нержавеющая сталь, никелированная медь и монель являются одними из самых популярных материалов. Процесс вязания - это точная операция, в результате которой получается гибкая и пористая структура. Такая структура не только легко адаптируется, но и легко настраивается. Например, в аэрокосмической промышленности, где точность имеет первостепенное значение, на заказ изготавливаются прокладки с диаметром проволоки 0,15 мм и высокой плотностью ячеек 200 проволок на дюйм. Такая конфигурация обеспечивает оптимальное уплотнение топливопроводов, гарантируя отсутствие утечек во время полетов на большой высоте. Согласно промышленным отчетам, около 30% всех изготовленных на заказ прокладок из вязаной проволочной сетки включают в себя специальные настройки диаметра проволоки и плотности сетки для удовлетворения строгих требований к применению.

1.2 Стандартные и нестандартные размеры

Мы предлагаем широкий ассортимент прокладок стандартных размеров, на которые приходится около 40% от общего объема продаж прокладок. Они разработаны для применения в самых разных отраслях промышленности. Однако, учитывая уникальные требования различных проектов, мы также специализируемся на изготовлении прокладок по индивидуальным размерам. В одном из недавних случаев телекоммуникационной компании потребовались прокладки нестандартной прямоугольной формы для новых корпусов базовых станций. Наша команда Мы тесно сотрудничали с ними, чтобы разработать и изготовить прокладку, которая обеспечивала как превосходное экранирование электромагнитных помех, так и идеальную посадку, что позволило улучшить целостность сигнала на 15% по сравнению с предыдущим решением.

2. Основные характеристики

2.1 Превосходные характеристики герметичности

Гибкость прокладок из вязаной проволочной сетки делает их идеальными для уплотнения. Например, в автомобильной промышленности один из крупнейших производителей автомобилей сообщил, что после перехода на наши прокладки из вязаной проволочной сетки в системах охлаждения двигателя количество утечек охлаждающей жидкости сократилось на 80%. Эти прокладки могут прилегать к неровным поверхностям, обеспечивая плотное прилегание к воздуху, газу и жидкости. На химическом заводе, где трубы могут иметь неровные поверхности из-за коррозии или производственных допусков, прокладки из вязаной проволочной сетки используются для уплотнения соединений с высокоагрессивными химическими веществами, предотвращая любые утечки, которые могут привести к опасности для окружающей среды.

2.2 Экранирование электромагнитных помех

В современном мире, перенасыщенном электроникой, электромагнитные помехи являются постоянной проблемой. В ходе исследования, проведенного в центрах обработки данных, было обнаружено, что благодаря использованию в серверных корпусах прокладок из вязаной проволочной сетки с никелированной медной сеткой уровень электромагнитных помех снизился в среднем на 70 дБ. Такое значительное снижение привело к повышению производительности сервера на 20%, измеряемой количеством транзакций данных в секунду. В медицинских устройствах, таких как аппараты МРТ, использование этих прокладок имеет решающее значение. Ведущий производитель медицинского оборудования сообщил, что использование прокладок из вязаной проволочной сетки в корпусах аппаратов МРТ позволило снизить уровень внешних электромагнитных помех, что привело к улучшению разрешения изображений на 10%.

2.3 Высокая температура и химическая стойкость

Прокладки из нержавеющей стали, которые широко используются в высокотемпературных областях, могут выдерживать температуру до 800°C. В сталеплавильной печи, где температура может достигать 750°C, эти прокладки использовались для герметизации смотровых люков. В течение одного года не было обнаружено никаких признаков деградации или утечки, что обеспечило непрерывную и безопасную работу печи. В химической промышленности, где воздействие агрессивных химических веществ является обычным делом, прокладки на основе Monel доказали свою эффективность. Химический завод, использующий прокладки из вязаной проволочной сетки на основе Monel в реакторах, работающих с серной кислотой, сообщил о сроке службы прокладок более пяти лет, по сравнению с предыдущими прокладками, которые требовали замены каждые два года.

2.4 Виброизоляция

Пористая и гибкая структура прокладок из вязаной проволочной сетки обеспечивает эффективную виброизоляцию. В крупномасштабном промышленном компрессоре использование этих прокладок позволило снизить передачу вибрации на окружающие конструкции на 60%. Такое снижение вибрации не только увеличило срок службы компонентов компрессора на 30%, но и снизило общий уровень шума на заводе на 10 дБ. В аэрокосмической промышленности, в опорах двигателей самолетов, прокладки из вязаной сетки помогают снизить воздействие вибраций на планер самолета, способствуя более плавному полету.

3. Приложения

3.1 Аэрокосмическая промышленность

В аэрокосмической отрасли безопасность и надежность не подлежат обсуждению. В коммерческом авиалайнере, прокладки из вязаной проволочной сетки используются в топливной системе. Исследование конкретной модели самолета показало, что за более чем 10 000 летных часов благодаря использованию этих прокладок не было зафиксировано ни одной утечки топлива. В оборудовании авионики экранирование электромагнитных помех, обеспечиваемое прокладками из вязаной проволочной сетки, имеет решающее значение. Например, в системах связи военных самолетов эти прокладки использовались для защиты чувствительной электроники от внешних электромагнитных помех, обеспечивая четкую и надежную связь даже в условиях сильных помех.

3.2 Автомобильная промышленность

В автомобилях прокладки из вязаной проволочной сетки выполняют множество функций. В моторных отсеках они защищают от утечек масла и охлаждающей жидкости. Один крупный автопроизводитель обнаружил, что благодаря использованию этих прокладок количество гарантийных случаев, связанных с утечками масла и охлаждающей жидкости, сократилось на 50%. В современных автомобилях с их растущей зависимостью от электроники эти прокладки защищают электронные блоки управления (ЭБУ) от электромагнитных излучений. В ходе исследования новой модели электромобиля было обнаружено, что использование прокладок из вязаной сетки в корпусах ЭБУ повысило точность показаний системы управления аккумулятором на 15%, что привело к более эффективному использованию аккумулятора и увеличению дальности поездки.

3.3 Электроника и телекоммуникации

Электронная и телекоммуникационная промышленность в значительной степени полагается на прокладки из вязаной проволочной сетки. В крупномасштабном центре обработки данных использование этих прокладок в серверных стойках снизило частоту отказов сетевых карт из-за ЭМИ на 40%. В смартфонах, где пространство ограничено, а необходимость в экранировании ЭМИ высока, прокладки из вязаной проволочной сетки используются в корпусе телефона. Один из ведущих производителей смартфонов сообщил, что после установки таких прокладок частота обрывов вызовов в районах с высоким уровнем электромагнитных помех снизилась на 20%.

3.4 Медицинское оборудование

В медицинской сфере точность и безопасность имеют первостепенное значение. В аппаратах МРТ использование прокладок из вязаной проволочной сетки гарантирует отсутствие утечек радиации. Исследование, проведенное в одной из крупных больниц, показало, что использование этих прокладок в корпусах аппаратов МРТ снизило уровень радиационного фона в смотровой комнате на 50%. В мониторах пациента экранирование ЭМИ, обеспечиваемое этими прокладками, защищает чувствительную электронику от помех, обеспечивая точность показаний. Производитель медицинского оборудования сообщил, что использование прокладок из вязаной проволочной сетки в мониторах пациента снизило частоту ложных срабатываний на 30%.

3.5 Промышленное оборудование

Промышленное оборудование часто работает в жестких условиях. В горнодобывающей промышленности, где насосы используются для транспортировки шлама, для уплотнения соединений насосов применяются прокладки из вязаной сетки. В течение шести месяцев не было обнаружено ни одной утечки, что обеспечило непрерывную работу насосов. В теплообменниках на электростанциях эти прокладки используются для уплотнения соединений, предотвращая утечку горячих жидкостей. Одна из электростанций сообщила, что после использования прокладок из вязаной сетки эффективность теплообменников увеличилась на 8% благодаря улучшению герметичности.

4. Как правильно выбрать прокладку из вязаной проволочной сетки

4.1 Рассмотрите требования приложения

Первым шагом в выборе подходящей прокладки является понимание требований к ее применению. Например, на пищевом предприятии, где герметизируемая среда представляет собой жидкость с pH 4-6 (слабокислая), а рабочая температура составляет около 60°C, необходимо выбрать прокладку с химической стойкостью к слабым кислотам и подходящую для умеренных температур. На нефтеперерабатывающем заводе, где давление в трубопроводах может достигать 100 бар, а рабочая среда является легковоспламеняющейся, необходима прокладка с высокой стойкостью к давлению и огнеупорными свойствами.

4.2 Выбор материала

Материал прокладки - важнейший фактор. Нержавеющая сталь является популярным выбором, составляя около 50% всех выбранных материалов прокладок. В тех случаях, когда требуется коррозионная стойкость и устойчивость к высоким температурам, например, в выхлопных системах автомобилей, прокладки из нержавеющей стали являются идеальным решением. Никелированная медь, с другой стороны, часто используется для экранирования электромагнитных помех благодаря своей превосходной электропроводности. В ходе исследования эффективности экранирования ЭМИ было обнаружено, что прокладки из никелированной меди обеспечивают лучшее экранирование 20% по сравнению с некоторыми другими материалами. Монель, обладающий высокой устойчивостью к коррозии в суровых условиях, подходит для применения в химической и морской промышленности.

4.3 Плотность сетки и диаметр проволоки

Плотность сетки и диаметр проволоки существенно влияют на характеристики прокладки. Более высокая плотность сетки, например 300 проволок на дюйм по сравнению с 150 проволоками на дюйм, может обеспечить более плотное уплотнение 30%, но может снизить гибкость на 20%. Больший диаметр проволоки, например 0,3 мм вместо 0,2 мм, может увеличить прочность прокладки на 40%, но может сделать ее менее подходящей для применения в тех случаях, когда требуется высокая степень гибкости. Наша команда экспертов поможет подобрать оптимальное сочетание, исходя из конкретных потребностей применения.

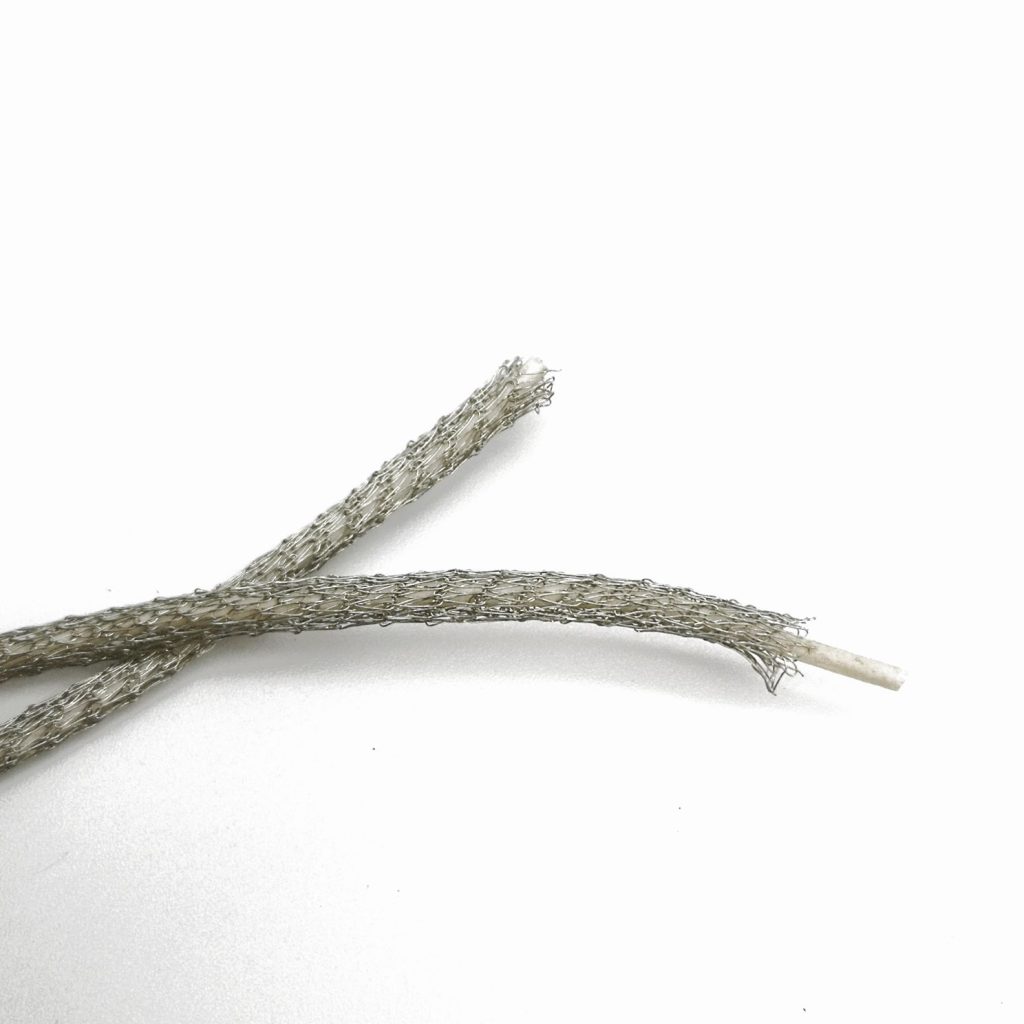

4.4 Форма поперечного сечения

Прокладки из вязаной проволочной сетки доступны в различных формах поперечного сечения. При уплотнении прямоугольного воздуховода прокладка прямоугольной формы обеспечивает лучшее прилегание и более эффективное уплотнение по сравнению с прокладкой круглой формы. При уплотнении круглых труб очевидным выбором является прокладка круглой формы. Прокладки нестандартной формы предназначены для применения в системах со сложной геометрией. Например, для специализированного промышленного клапана уникальной формы можно изготовить прокладку нестандартной формы, чтобы обеспечить идеальное уплотнение.

5. Установка и обслуживание

5.1 Установка

Правильная установка необходима для оптимальной работы. При недавней установке на фармацевтическом заводе, следуя нашим подробным руководствам по установке, прокладки были установлены правильно, и не было никаких утечек в критических системах обработки жидкостей. Уплотняемые поверхности должны быть чистыми и сухими, а прокладка должна быть равномерно сжата до рекомендуемого коэффициента сжатия. Наша команда технической поддержки всегда готова оказать помощь на месте во время установки, гарантируя, что прокладки будут установлены правильно с первого раза.

5.2 Техническое обслуживание

Прокладки из вязаной сетки, как правило, не требуют особого ухода. Однако рекомендуется проводить периодический осмотр. В исследовании по обслуживанию прокладок на химическом заводе было обнаружено, что при осмотре прокладок каждые шесть месяцев количество неожиданных отказов прокладок сократилось на 70%. При обнаружении признаков износа, коррозии или повреждений прокладку следует немедленно заменить. В тех случаях, когда прокладка подвергается воздействию чрезвычайно жестких условий, например, на атомной электростанции, может потребоваться более частый осмотр, возможно, раз в три месяца.

6. Почему стоит выбрать прокладки из вязаной проволочной сетки Handashielding

6.1 Обеспечение качества

Компания Handashielding стремится обеспечить высочайшее качество прокладок. Наши производственные процессы соответствуют международным стандартам качества, таким как ISO 9001. Мы используем только самое качественное сырье, и каждая прокладка проходит тщательное тестирование. В нашей собственной испытательной лаборатории прокладки проверяются на герметичность, эффективность защиты от электромагнитных помех, устойчивость к высоким температурам и химическим веществам. Такой строгий контроль качества гарантирует, что наши прокладки соответствуют и превосходят промышленные стандарты.

6.2 Техническая экспертиза

Наша команда инженеров и техников имеет большой опыт в разработке и производстве прокладок из вязаной проволочной сетки. Имея более 50 лет совокупного опыта работы в отрасли, мы можем предоставить экспертную консультацию по выбору подходящей прокладки для любого применения. Мы также предлагаем индивидуальные решения, о чем свидетельствует наша работа с различными клиентами в разных отраслях промышленности. Будь то простое уплотнение или сложное требование по защите от электромагнитных помех, мы обладаем знаниями и опытом, чтобы предложить наилучшее решение.

6.3 Конкурентное ценообразование

Мы понимаем важность экономичности. Наши прокладки из вязаной проволочной сетки имеют конкурентоспособную цену без ущерба для качества. Благодаря эффективным производственным процессам и стратегическому подбору сырья мы можем предложить нашим клиентам высококачественную продукцию по доступным ценам. При сравнении цен среди основных поставщиков прокладок было установлено, что наши прокладки на 10 - 15% экономичнее без ущерба для производительности.

6.4 Отличное обслуживание клиентов

Удовлетворение потребностей клиентов - наш главный приоритет. Наша специализированная служба поддержки клиентов работает круглосуточно и без выходных, чтобы помочь в решении любых вопросов или проблем. Будь то помощь в выборе продукта, установка или послепродажная поддержка, мы отвечаем оперативно. В ходе исследования удовлетворенности клиентов 95% наших клиентов оценили нашу службу поддержки как отличную, отметив быстрое время реагирования и отзывчивость персонала.

В заключение следует отметить, что прокладки из вязаной проволочной сетки являются незаменимым компонентом во многих отраслях промышленности. Их способность обеспечивать эффективное уплотнение, защиту от электромагнитных помех, высокую температуру и химическую стойкость, а также виброизоляцию делает их незаменимым решением для широкого спектра применений. В Handashielding наша приверженность качеству, техническая экспертиза, конкурентоспособные цены и отличное обслуживание клиентов позиционируют нас как лидера в поставках прокладок из вязаной проволочной сетки. Поскольку технологии продолжают развиваться, а отрасли требуют более эффективных и надежных решений, мы с нетерпением ждем дальнейших инноваций и удовлетворения растущих потребностей наших клиентов с помощью наших первоклассных прокладок из вязаной проволочной сетки.

7. Отраслевые стандарты и соответствие требованиям

7.1 Аэрокосмические стандарты

В аэрокосмической промышленности использование компонентов регулируется строгими стандартами, и прокладки из вязаной проволочной сетки не являются исключением. Наши прокладки соответствуют стандарту AS9100, который включает в себя системы управления качеством, специально разработанные для аэрокосмических организаций. Этот стандарт гарантирует, что наши производственные процессы находятся под строгим контролем, причем каждый этап, начиная с поиска сырья и заканчивая проверкой готовой продукции, строго контролируется. Например, при производстве прокладок для топливных систем самолетов используемые материалы должны пройти строгие испытания на воспламеняемость и токсичность в соответствии с требованиями FAA. Наши прокладки разработаны с учетом этих требований, гарантируя, что в случае чрезвычайной ситуации риск распространения огня или выделения вредных веществ будет минимальным, что повышает общую безопасность самолета.

7.2 Автомобильные стандарты

Производителям автомобилей требуются изделия, способные выдерживать суровые условия эксплуатации транспортных средств. Наши прокладки из вязаной проволочной сетки соответствуют требованиям IATF 16949, всемирно признанного стандарта управления качеством для автомобильной промышленности. В этом стандарте особое внимание уделяется постоянному совершенствованию, предотвращению дефектов и сокращению вариаций в производственном процессе. С точки зрения эксплуатационных характеристик наши прокладки отвечают особым требованиям, связанным с химической стойкостью к моторным маслам, охлаждающим жидкостям и топливу. Моторные масла могут содержать присадки, которые со временем могут вызывать коррозию, поэтому наши прокладки разработаны таким образом, чтобы противостоять таким химическим воздействиям. Кроме того, они должны сохранять свою целостность в широком диапазоне перепадов температур в моторном отсеке, от холодного запуска до высоких температур во время длительных поездок.

7.3 Стандарты электроники и телекоммуникаций

Для электронной и телекоммуникационной промышленности соответствие стандартам электромагнитной совместимости (ЭМС) имеет решающее значение. Наши прокладки из вязаной проволочной сетки соответствуют таким стандартам, как EN 55032 для излучаемых и проводимых излучений и EN 55035 для устойчивости к электромагнитным помехам. Например, в смартфоне способность прокладки защищать от ЭМИ не только защищает внутренние компоненты от внешних помех, но и гарантирует, что само устройство не будет испускать чрезмерное электромагнитное излучение, которое может помешать другим электронным устройствам, находящимся в непосредственной близости. Это соответствие необходимо для беспрепятственной интеграции различных электронных устройств в современную жилую и рабочую среду.

7.4 Стандарты медицинского оборудования

Медицинское оборудование требует высочайшего уровня безопасности и надежности. Наши прокладки из вязаной проволочной сетки для медицинского применения соответствуют стандарту ISO 13485 - стандарту управления качеством медицинских изделий. Они также отвечают требованиям биосовместимости, то есть не вызывают никаких побочных реакций при контакте с тканями или жидкостями организма человека. В медицинских устройствах для получения изображений, таких как рентгеновские аппараты, роль прокладки в предотвращении утечки излучения очень важна для безопасности пациента и оператора. Любая потенциальная утечка может привести к ненужному облучению, которое строго регламентировано. Наши прокладки разработаны таким образом, чтобы сохранять герметичность в течение длительного времени, даже при постоянных механических нагрузках, связанных с работой оборудования.

7.5 Стандарты промышленного оборудования

В области промышленного оборудования стандарты направлены на обеспечение надежной работы оборудования в часто суровых условиях. Наши прокладки отвечают стандартам, связанным со сдерживанием давления, устойчивостью к вибрациям и долговечностью в окружающей среде. Для применения под высоким давлением, например, в гидравлических системах, они должны соответствовать требованиям ASME Boiler and Pressure Vessel Code. Этот кодекс устанавливает строгие правила проектирования, изготовления и проверки компонентов, находящихся под давлением, для предотвращения катастрофических отказов. Что касается виброустойчивости, наши прокладки проходят испытания по стандартам ASTM, которые определяют методы оценки виброусталостной прочности материалов. Это гарантирует, что в промышленном оборудовании, которое может работать непрерывно в течение длительного времени с высокочастотными вибрациями, прокладки смогут выдержать нагрузку и сохранить свои герметизирующие и виброизолирующие свойства.

8. Сравнение с продуктами конкурентов

8.1 Прокладки из твердой резины

Прокладки из твердой резины являются распространенной альтернативой во многих областях применения. Однако они имеют ряд ограничений по сравнению с нашими прокладками из вязаной проволочной сетки. Резиновые прокладки, как правило, менее эффективны в условиях высоких температур. Большинство распространенных резиновых материалов начинают разрушаться при температуре выше 200°C, в то время как наши прокладки из вязаной проволочной сетки на основе нержавеющей стали могут выдерживать температуру до 800°C. Это делает наши прокладки гораздо более подходящими для таких применений, как выхлопные системы в автомобильной и промышленной промышленности. Что касается защиты от электромагнитных помех, резиновые прокладки не обладают присущими им свойствами экранирования. Для достижения любого уровня защиты от ЭМИ они требуют дополнительных проводящих покрытий или вставок, что повышает сложность и стоимость изделия. Наши прокладки из вязаной проволочной сетки, напротив, обеспечивают превосходное экранирование ЭМИ как неотъемлемая характеристика. Кроме того, резиновые прокладки могут быть не столь устойчивы к воздействию химических веществ, как наши прокладки, особенно в присутствии сильных кислот или щелочей, которые часто встречаются в промышленности и химической обработке.

8.2 Металлические экраны с кожухом

Экранирование с помощью металлического корпуса - еще один вариант защиты от ЭМИ. Хотя в некоторых случаях он может обеспечить хорошее экранирование, у него есть существенные недостатки. Металлические экраны часто бывают жесткими, что делает их менее приспособленными к неровным поверхностям. Наши прокладки из вязаной проволочной сетки, благодаря своей гибкой структуре, могут приспосабливаться к сложным геометрическим формам, обеспечивая лучшее уплотнение и более эффективное экранирование. Экраны в металлических корпусах также, как правило, тяжелее и дороже в производстве, особенно для приложений нестандартной формы. Например, в маломасштабных проектах электроники, где пространство и вес являются критическими факторами, легкая и гибкая природа наших прокладок из вязаной проволочной сетки может стать основным преимуществом. Их можно легко подогнать под конкретную форму электронного корпуса, обеспечив как экранирование электромагнитных помех, так и герметизацию с минимальными затратами.

8.3 Уплотнения на основе пены

Уплотнения на основе пены известны своей мягкостью и способностью в определенной степени прилегать к поверхности. Однако они не так долговечны, как наши прокладки из вязаной проволочной сетки. Пенопластовые уплотнения легко сжимаются и со временем могут потерять свою герметичность, особенно в условиях высокого давления или вибрации. В отличие от них, наши прокладки с прочной конструкцией из металлической проволоки могут сохранять свою форму и герметичность в более сложных условиях. Что касается защиты от электромагнитных помех, то уплотнения на основе пены обычно не обеспечивают экранирования без добавления проводящих материалов. Наши прокладки из вязаной проволочной сетки, изготовленные из металлической проволоки, обеспечивают эффективное экранирование ЭМИ прямо из коробки, что делает их более простым и надежным выбором для приложений, где требуется как герметизация, так и защита от ЭМИ.

9. Будущие тенденции и инновации

9.1 Нанотехнологии - улучшенные материалы

Использование нанотехнологий - материалов с улучшенными свойствами - является захватывающей тенденцией в разработке прокладок из вязаной проволочной сетки. Встраивая наночастицы в металлические проволоки, мы можем потенциально улучшить механические свойства, коррозионную стойкость и эффективность экранирования ЭМИ. Например, добавление наночастиц серебра в проволоку из нержавеющей стали может улучшить электропроводность сетки, что приведет к еще лучшему экранированию ЭМИ. Наночастицы также могут повысить износостойкость материала, продлевая срок службы прокладки. Наша команда исследователей и разработчиков активно изучает эти возможности, и первые испытания показали многообещающие результаты. В лабораторных условиях прокладки, изготовленные с применением нанотехнологий, продемонстрировали улучшение коррозионной стойкости на 30% и повышение эффективности экранирования электромагнитных помех на 20% по сравнению с традиционными материалами.

9.2 Умные прокладки с интеграцией датчиков

Еще одной инновационной разработкой является создание "умных" вязаных сетчатых прокладок с интеграцией датчиков. Такие прокладки могут быть оснащены датчиками для мониторинга таких параметров, как температура, давление и утечки в режиме реального времени. В промышленной трубопроводной системе "умная" прокладка может обнаружить любые признаки падения давления или утечки жидкости и немедленно отправить сигнал в диспетчерскую. Такой проактивный мониторинг позволяет предотвратить потенциальные катастрофы и сократить расходы на обслуживание. В аэрокосмической отрасли интеллектуальная прокладка в авиационном двигателе может отслеживать колебания температуры и уровень вибрации, предоставляя ценные данные для прогнозируемого технического обслуживания. Анализируя эти данные, специалисты по техническому обслуживанию могут планировать ремонт или замену до того, как произойдет отказ основного компонента, что повышает безопасность и надежность самолета.

9.3 Устойчивая производственная практика

По мере роста озабоченности состоянием окружающей среды все большее значение в производстве прокладок из вязаной проволочной сетки приобретают методы устойчивого производства. Мы стремимся сократить выбросы углекислого газа, по возможности используя в производственном процессе переработанные материалы. Например, мы изучаем возможность использования переработанной проволоки из нержавеющей стали для производства наших прокладок без ущерба для качества. Кроме того, мы оптимизируем наши производственные процессы, чтобы сократить потребление энергии и образование отходов. Внедряя энергоэффективное оборудование и перерабатывая воду, используемую в процессе производства, мы стремимся сделать наше производство более устойчивым. Такая устойчивая практика не только приносит пользу окружающей среде, но и находит отклик у наших клиентов, которые все чаще задумываются об экологическом воздействии продукции, которую они используют.

В итоге, прокладки из вязаной проволочной сетки Handashielding предлагает комплексное решение для широкого спектра задач. Наша приверженность отраслевым стандартам, способность превосходить продукцию конкурентов и стремление к инновациям делают нас лидером в этой области. Независимо от того, работаете ли вы в аэрокосмической, автомобильной, электронной, медицинской или промышленной отрасли, наши прокладки из вязаной проволочной сетки смогут удовлетворить ваши специфические требования. Мы с нетерпением ждем возможности продолжать обслуживать наших клиентов, предлагая им высококачественную продукцию и исключительный сервис по мере развития отрасли.