Handa circular fingerstrips in electromagnetic interference (EMI) shielding

Handa circular fingerstrips are essential components in the design and maintenance of electronic systems requiring reliable EMI shielding and grounding. Their unique design and material properties make them suitable for a wide range of applications, ensuring the integrity and performance of sensitive electronic equipment.

Handa circular fingerstrips in electromagnetic interference (EMI) shielding

Оглавление

Введение

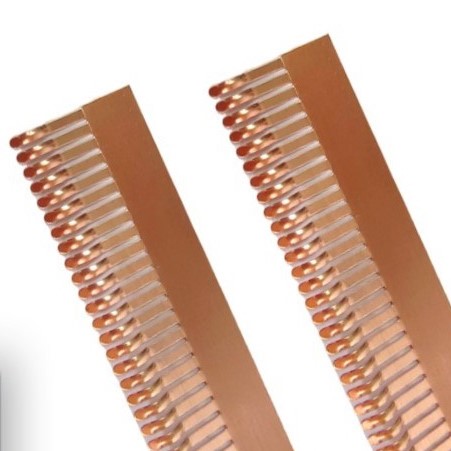

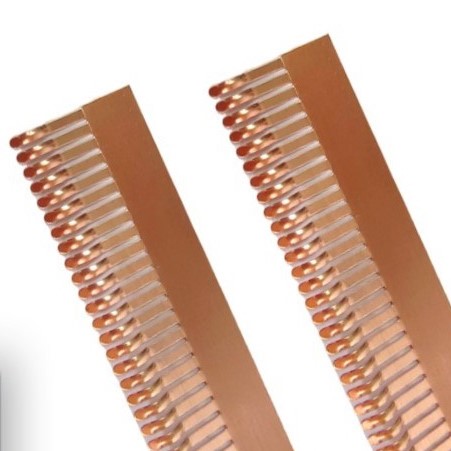

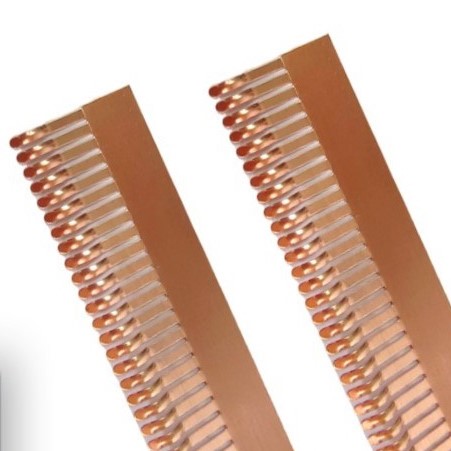

In the realm of electromagnetic interference (EMI) shielding, Handa circular fingerstrips stand out as a pivotal component, offering robust solutions for grounding and EMI protection across various industries. These specialized gaskets are engineered to form large-diameter contact rings, ensuring continuous electrical contact and effective shielding in high-frequency equipment.

Understanding Circular Fingerstrips

Circular fingerstrips, also known as circular finger gaskets, are designed to provide reliable EMI shielding and grounding. Their unique circular design allows them to form large-diameter contact rings, ensuring continuous electrical contact and shielding effectiveness. The spring-like nature of the fingers allows them to maintain consistent contact pressure, accommodating variations in surface flatness and ensuring reliable performance over time.

Дизайн и функциональность

Handa circular fingerstrips are meticulously crafted to meet the stringent demands of modern electronic systems. The design incorporates a series of conductive fingers arranged in a circular pattern, typically made from materials such as beryllium copper, known for its excellent electrical conductivity and mechanical strength. These fingers are designed to make contact with mating surfaces, creating a continuous conductive path that effectively shields against EMI. The spring-like nature of the fingers allows them to maintain consistent contact pressure, accommodating variations in surface flatness and ensuring reliable performance over time.

Приложения

Handa circular fingerstrips are versatile components employed in various applications requiring effective EMI shielding and grounding:

- High-Frequency Equipment: They are commonly used in high-frequency equipment to prevent EMI, ensuring the integrity and performance of sensitive electronic components.

- Shielded Enclosures: In shielded enclosures, circular fingerstrips provide a reliable seal, maintaining the enclosure’s shielding effectiveness and preventing the ingress of external electromagnetic fields.

- Grounding Applications: They are employed to establish a low-resistance path to ground, facilitating the dissipation of unwanted electrical charges and enhancing the safety and performance of electronic systems.

Основные характеристики

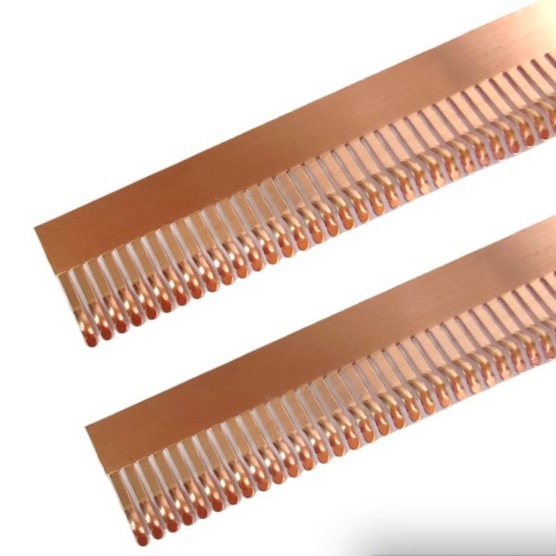

When selecting Handa circular fingerstrips, consider the following specifications:

- Материал: Beryllium copper is commonly used due to its superior electrical conductivity and mechanical properties.

- Размеры: Fingerstrips are available in various sizes to accommodate different diameters and application requirements.

- Mounting Options: They can be mounted using clip-on, snap-on, or stick-on methods, depending on the design of the equipment and the specific application needs.

Производственный процесс

The production of Handa circular fingerstrips involves several key steps:

- Выбор материала: Handa Shielding typically selects бериллиевая медь (BeCu) as the primary material due to its high electrical conductivity, corrosion resistance, and fatigue strength.

- Design Dimensions and Thickness: Determine the specific dimensions (length, width, thickness) and material thickness required for the circular fingerstrip.

- Stamping or Extrusion: The primary method for producing circular fingerstrips involves stamping or extruding the beryllium-copper alloy into the desired shape.

- Edge Finishing: After forming, the edges of the circular fingerstrip may require finishing to remove any sharp corners or burrs.

- Surface Treatment: Optional surface treatments like plating or coating can be applied to enhance corrosion resistance and ensure compatibility with mating surfaces.

Лучшие практики по установке и обслуживанию

To ensure optimal performance and longevity of Handa circular fingerstrips:

- Proper Installation: Ensure that the fingerstrip is correctly positioned and securely mounted to maintain consistent contact pressure and alignment.

- Регулярный осмотр: Periodically inspect the fingerstrips for signs of wear, corrosion, or damage. Replace or repair as necessary to maintain effective shielding and grounding.

- Environmental Considerations: Be mindful of the operating environment, including factors such as temperature, humidity, and exposure to chemicals, which can affect the performance and lifespan of the fingerstrips.

Заключение

Handa circular fingerstrips are essential components in the design and maintenance of electronic systems requiring reliable EMI shielding and grounding. Their unique design and material properties make them suitable for a wide range of applications, ensuring the integrity and performance of sensitive electronic equipment. By understanding their design, applications, and best practices for use, engineers and technicians can leverage the full potential of Handa circular fingerstrips to enhance the reliability and performance of complex systems operating in demanding conditions.

Вам также может понравиться

-

Knitted Wire Mesh Gaskets: Leading in Performance – From Precision EMI Shielding to Robust Vibration Absorption

Knitted Wire Mesh Gaskets: Leading in Performance – From Precision EMI Shielding to Robust Vibration AbsorptionРешения и материалы для экранирующих прокладок

Прокладки из вязаной проволочной сетки

Knitted Wire Mesh Gaskets 1. Introduction2. Product Overview2.1 Construction2.2 Standard and Custom Sizes3. Key Features3.1 Excellent Sealing Performance3.2 EMI Shielding3.3 High - Temperature and Chemical Resistance3.4 Vibration Isolation4. Applications4.1 Aerospace Industry4.2 Automotive Industry4.3 Electronics and Telecommunications4.4 Medical Equipment4.5 Industrial Machinery5.......

-

How Canted Coil Springs for EMI Shielding Overcome Challenges in Long-Term High-Temperature Applications

How Canted Coil Springs for EMI Shielding Overcome Challenges in Long-Term High-Temperature ApplicationsНовости

Canted Coil Springs for EMI Shielding 1. Introduction1.1. Overview of Canted Coil Springs for EMI Shielding1.2. The Challenges of Long-Term High-Temperature Operation2. Applications of Canted Coil Springs for EMI Shielding2.1. High-Voltage Power Equipment2.2. Rail Transportation2.3. New Energy Vehicles2.4. Oil Exploration......

-

Electromagnetic Shielding Spiral Tubes for Vacuum Equipment

Electromagnetic Shielding Spiral Tubes for Vacuum EquipmentЭкранирование EMI/EMC | Экранирование RFI | Прокладки EMI

Спиральная прокладка для экранирования радиочастот/электромагнитных помех

Electromagnetic Shielding Spiral Tubes for Vacuum Equipment Introduction: In today’s high-tech industries, electromagnetic interference (EMI) is a significant concern, especially for sensitive equipment like vacuum systems, precision instruments, and electronic devices. EMI can cause signal distortion, data loss, and equipment......

-

Handa Flexi Shield Spiral Gasket with excellent EMI protection

Handa Flexi Shield Spiral Gasket with excellent EMI protectionЭкранирование EMI/EMC | Экранирование RFI | Прокладки EMI

Спиральная прокладка для экранирования радиочастот/электромагнитных помех

Handa Flexi Shield Spiral Gaskets Design Features of Handa Flexi ShieldApplications of Handa Flexi Shield Spiral GasketSpecifications of Handa Flexi Shield Spiral GasketDesign Considerations for Handa Flexi Shield Spiral GasketKey Benefits of Handa Flexi Shield Spiral GasketsCustomization Options for Handa......

-

Экранирующие прокладки из вязаной проволочной сетки EMI/RFI с высокой эффективностью экранирования

Экранирующие прокладки из вязаной проволочной сетки EMI/RFI с высокой эффективностью экранированияПолоски для пальцев

Прямоугольная экранирующая планка

Knitted Wire Mesh EMI/RFI Shielding Gaskets Introduction to Knitted Wire Mesh EMI/RFI Shielding GasketsWhat is EMI and RFI Shielding?How Knitted Wire Mesh EMI/RFI Shielding Gaskets WorkMaterials Used in Knitted Wire Mesh EMI/RFI Shielding GasketsAdvantages of Knitted Wire Mesh EMI/RFI Shielding......