Electromagnetic Shielding Spiral Tubes for New Energy Vehicles

Introduction

With the rapid advancement of new energy vehicles (NEVs), electromagnetic compatibility (EMC) issues have become increasingly prominent. High-voltage battery systems, motor drive units, and on-board electronic devices generate intense electromagnetic interference (EMI) during operation, which can compromise vehicle safety and reliability. As a leading enterprise in the field of electromagnetic shielding, Handa’s electromagnetic shielding spiral tubes, with their innovative design and superior performance, provide efficient EMI solutions for the new energy vehicle industry. This article will delve into the key applications and technical advantages of electromagnetic shielding spiral tubes in new energy vehicles, exploring how they address the evolving challenges of modern automotive electrification.

Оглавление

I. Electromagnetic Interference Challenges in New Energy Vehicles

Core components of new energy vehicles, such as power battery packs (BMS), drive motors, on-board chargers (OBC), and high-voltage wiring harnesses, generate high-frequency electromagnetic noise during operation. Without effective suppression, this can lead to the following issues:

- Abnormal signal transmission: Interference with CAN bus and sensor signals, affecting the stability of vehicle control systems. In critical scenarios, this could delay or distort crucial data transmission between vehicle modules.

- Malfunction of electronic devices: False triggering or failure of in-vehicle entertainment systems and ADAS (Advanced Driver Assistance Systems). For ADAS in particular, such malfunctions pose significant risks to driving safety.

- Safety hazards: EMI from high-voltage systems may cause misjudgment by the Battery Management System (BMS), potentially affecting the overall safety of the vehicle, including risks of overcharging or thermal runaway.

Traditional electromagnetic shielding solutions (such as metal shields and conductive fabrics) have limitations in terms of flexibility, weight, and cost. In contrast, electromagnetic shielding spiral tubes, with their unique structure, have emerged as an ideal choice for EMC optimization in new energy vehicles, offering a balance of performance and practicality.

II. Working Principle of Electromagnetic Shielding Spiral Tubes

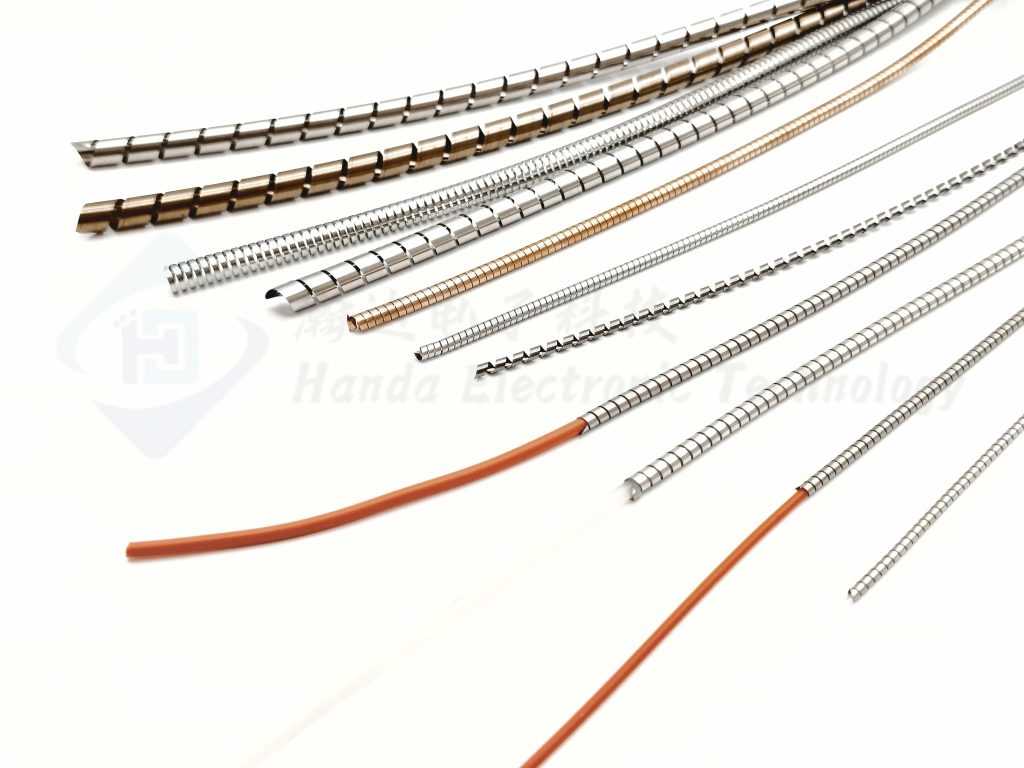

Electromagnetic shielding spiral tubes are made of high-conductivity metal materials (such as silver-plated copper and copper-nickel alloys) and form a continuous shielding layer through precision spiral winding technology. Their core advantages include:

- Eddy current shielding effect: The spiral structure generates reverse induced current in the alternating electromagnetic field, counteracting external interference effectively.

- Broadband shielding: Suitable for a wide frequency range from low frequencies (such as motor harmonics) to high frequencies (such as 5G communication interference), ensuring comprehensive protection.

- Flexibility and bendability: Compared with rigid shields, spiral tubes are more adaptable to the complex wiring harness layouts in new energy vehicles, simplifying installation and reducing the risk of damage during assembly.

III. Innovative Applications of Handa’s Electromagnetic Shielding Spiral Tubes in New Energy Vehicles

1. EMI Suppression in Power Battery Systems (BMS)

The Battery Management System (BMS) of new energy vehicles is extremely sensitive to the electromagnetic environment. Even minor interference can cause errors in voltage/current detection, affecting battery life and safety.

- Решение: Handar’s electromagnetic shielding spiral tubes are applied to the high-voltage wiring harnesses of battery packs, effectively isolating high-frequency noise generated by motors and inverters, and ensuring stable signal transmission of BMS.

- Test data: After a customer adopted Handar’s spiral tubes, the signal-to-noise ratio (SNR) of BMS signals increased by 40%, and the false alarm rate decreased by 60%, significantly improving the reliability of the battery system.

2. EMC Optimization for Drive Motors and Inverters

The motor drive system is a major EMI source in new energy vehicles, and its PWM modulated waves generate strong harmonic interference that can propagate through wiring harnesses and affect other vehicle systems.

- Решение: Customized Handar spiral tubes are installed on the three-phase cables of motors, combined with magnetic rings to form a composite shielding system, suppressing common-mode and differential-mode interference effectively.

- Industry case: A new energy vehicle manufacturer successfully passed the CISPR 25 on-board EMC test after applying Handa’s products to motor wiring harnesses, meeting international standards and facilitating market access.

3. Protection for On-Board Chargers (OBC) and DC-DC Converters

On-board chargers generate high-frequency switching noise during fast charging, which may interfere with in-vehicle electronic devices, especially sensitive communication and control systems.

- Решение: Handar’s spiral tubes are used for shielding the input/output cables of OBC, reducing radiated interference while meeting lightweight requirements (30% lighter than traditional metal shielding layers), contributing to overall vehicle energy efficiency.

4. Signal Protection for Intelligent Networked Systems (5G/V2X)

With the development of intelligent driving technology, 5G and V2X communications have higher requirements for the electromagnetic environment, demanding minimal signal loss and interference.

- Решение: Handar’s high-frequency optimized spiral tubes (operating frequency range DC-40GHz) are used for shielding on-board antenna feeder lines, reducing signal crosstalk and improving communication stability, which is crucial for reliable vehicle-to-vehicle and vehicle-to-infrastructure communication.

IV. Core Advantages of Handa’s Electromagnetic Shielding Spiral Tubes

| Comparison Item | Traditional Shielding Solutions | Handa’s Electromagnetic Shielding Spiral Tubes |

| Shielding Effectiveness | 30-50dB | 60dB+ (up to 80dB for high-frequency optimized models) |

| Installation Flexibility | Rigid, difficult to bend | Flexible and can be wound, adapting to complex wiring |

| Weight | Relatively heavy | Lightweight (30%-50% lighter than metal shielding layers) |

| Environmental Adaptability | Prone to oxidation and corrosion | High temperature resistance, salt spray protection (-50℃~200℃), suitable for harsh automotive environments |

| Cost-Effectiveness | High maintenance costs | Long service life, maintenance-free, reducing long-term costs |

V. Future Trends: Development of Electromagnetic Shielding Spiral Tubes in New Energy Vehicles

With the popularization of 800V high-voltage platforms and SiC (silicon carbide) devices, EMI issues in new energy vehicles will become more complex, requiring more advanced shielding solutions. Handar is developing:

- Multi-layer composite shielding spiral tubes: Combining conductive polymer materials to further enhance shielding effectiveness and meet the higher requirements of next-generation vehicle systems.

- Intelligent adaptive shielding technology: Dynamically adjusting shielding parameters according to the intensity of environmental EMI, ensuring optimal performance under varying conditions.

- Ultra-lightweight design: Adapting to the lightweight needs of next-generation new energy vehicles, reducing energy consumption and improving driving range.

Conclusion

As a key technology for EMC optimization in new energy vehicles, electromagnetic shielding spiral tubes play an irreplaceable role in battery systems, motor drives, intelligent networking, and other fields. Hunan Handa, with its leading materials science and precision manufacturing processes, provides customers with high-performance and customized electromagnetic shielding solutions, supporting the development of safer and more reliable new energy vehicles.

If you are looking for a reliable electromagnetic shielding solution for new energy vehicles, please contact Handa’s technical team for free samples and professional consultation!