EMI Shielding Gasket Sample Request | Test Before You Specify

그리고 EMI Shielding Gasket Sample Request service is designed to help engineers and sourcing teams validate shielding performance before final specification and mass production. In EMI-critical applications, theoretical calculations alone are often insufficient. Requesting samples allows real-world testing to confirm fit, contact force, and shielding effectiveness under actual operating conditions.

By submitting an EMI shielding gasket sample request, customers can evaluate how different gasket structures, materials, and profiles perform within their specific enclosure design. This process helps identify potential issues related to compression range, tolerance stack-up, installation constraints, or long-term reliability at an early stage of development.

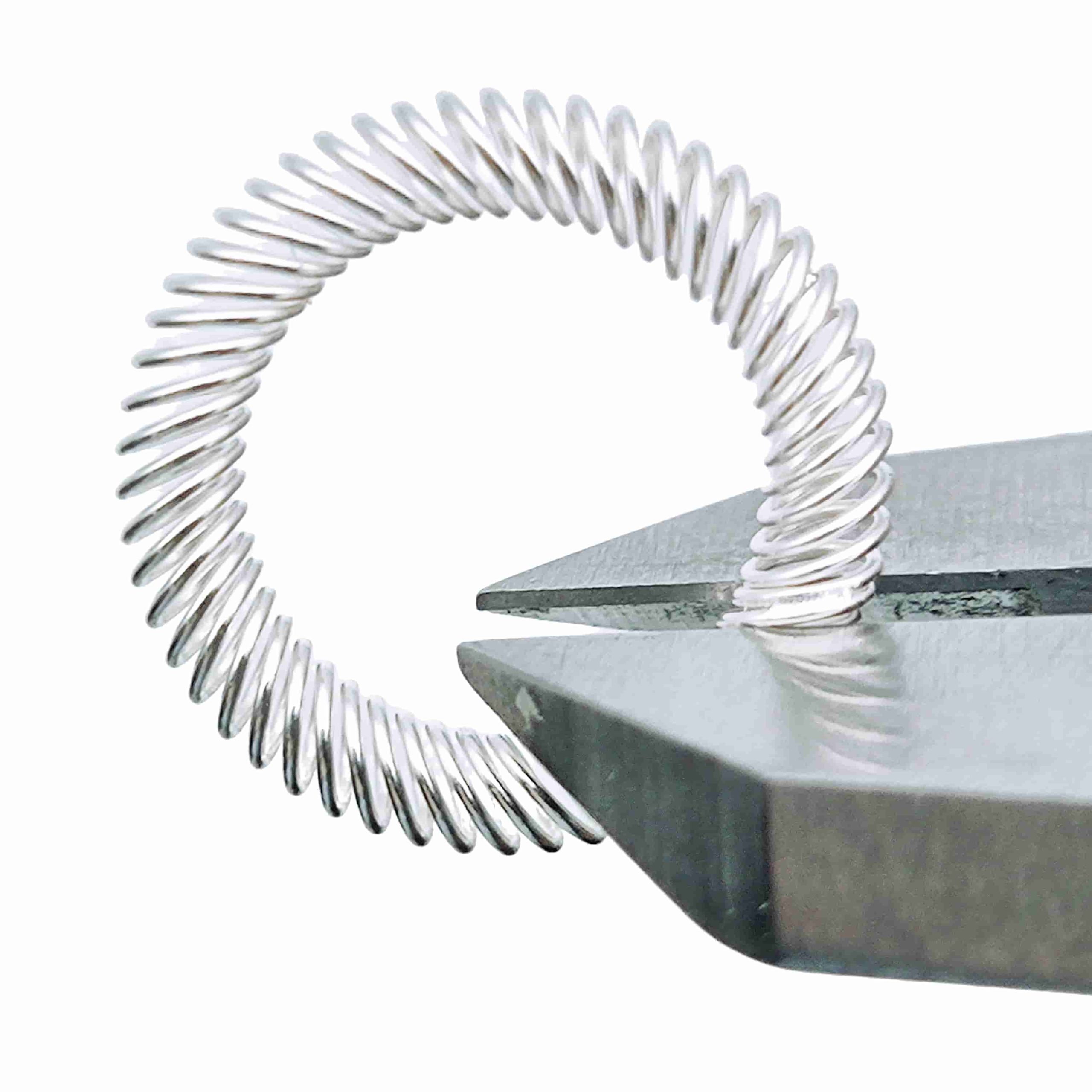

Our sample request service supports a wide range of EMI shielding gasket solutions, including canted coil spring gaskets, spiral spring gaskets, and other metal-based shielding designs. Samples can be provided in custom sizes, cut lengths, or formed configurations to match real application requirements. This enables accurate EMI testing, mechanical validation, and environmental evaluation before committing to volume production.

Requesting samples also streamlines supplier qualification and reduces project risk. Engineers gain confidence in performance data, while procurement teams avoid costly redesigns, requalification delays, or unexpected field failures.

With engineering support throughout the sampling process, we help customers select the most suitable EMI shielding gasket solution based on frequency range, environmental conditions, and mechanical constraints. Testing before specification ensures faster design approval, improved system reliability, and a smoother transition from prototype to production.

EMI Shielding Gasket Sample Request | Test Before You Specify

Meta Description

Submit an EMI shielding gasket sample request to evaluate material performance, fit, and shielding effectiveness before final specification in critical applications.

EMI Shielding Gasket Sample Request: A Practical Guide for Engineers and Buyers

When designing electronic systems that must meet strict EMC and EMI compliance standards, selecting the right shielding solution is critical. Before finalizing a specification, engineers and sourcing teams increasingly rely on an EMI shielding gasket sample request to validate performance, compatibility, and installation requirements in real-world conditions.

This article explains why an EMI shielding gasket sample request is essential, when it should be used, what information to provide, and how sample testing helps reduce design risk and procurement delays.

Why an EMI Shielding Gasket Sample Request Matters

An EMI shielding gasket plays a key role in maintaining electrical continuity and preventing electromagnetic leakage across enclosures, panels, and interfaces. However, gasket performance can vary significantly depending on material, compression range, mounting method, and operating environment.

Submitting an EMI shielding gasket sample request allows engineers to:

- Verify shielding effectiveness before mass production

- Evaluate mechanical fit within the actual groove or housing

- Confirm durability under vibration, temperature, and cycling

- Reduce the risk of late-stage design changes

For high-reliability industries, a sample request is not optional—it is part of a responsible engineering validation process.

When Should Engineers Submit an EMI Shielding Gasket Sample Request?

An EMI shielding gasket sample request is typically made during one of the following stages:

Early Design and Prototyping

Engineers request samples to compare different gasket structures, materials, or profiles during concept validation.

Pre-Qualification Testing

Samples are used for EMI testing, environmental exposure, and mechanical endurance testing before design freeze.

Supplier Evaluation

Procurement teams issue an EMI shielding gasket sample request to compare multiple suppliers under identical test conditions.

디자인 최적화

When existing shielding solutions show performance degradation, samples are requested to evaluate alternative designs.

Common Challenges Without Sample Testing

Skipping an EMI shielding gasket sample request can lead to several common problems:

- Poor shielding performance due to improper compression

- Installation difficulty caused by incompatible gasket geometry

- Premature failure from material relaxation or corrosion

- Increased costs due to redesign or requalification

These risks highlight why an EMI shielding gasket sample request should be a standard step in the selection process.

What Information to Include in an EMI Shielding Gasket Sample Request

To ensure meaningful evaluation, a complete EMI shielding gasket sample request should include the following details:

- Application description and enclosure type

- Target EMI shielding performance (frequency range, attenuation level)

- Available groove dimensions or mounting method

- Operating environment (temperature, humidity, vibration)

- Expected compression range and cycle life

- Quantity and sample format (cut length, formed gasket, welded ring)

Providing accurate information allows manufacturers to recommend the most suitable gasket configuration for testing.

Types of EMI Shielding Gaskets Commonly Requested as Samples

Depending on the application, an EMI shielding gasket sample request may involve different gasket types, including:

- Canted coil spring gaskets

- Spiral spring EMI gaskets

- Conductive elastomer gaskets

- Wire mesh or knitted gaskets

Among these options, spring-based EMI shielding gaskets are often preferred for applications requiring stable contact force and long-term reliability.

How Sample Testing Improves EMI Shielding Performance

By submitting an EMI shielding gasket sample request, engineers can directly measure how a gasket performs under actual operating conditions.

Typical evaluations include:

- EMI attenuation testing across relevant frequencies

- Contact resistance measurement

- Compression and recovery behavior

- Cycle life and mechanical fatigue

- 환경 내성 테스트

The data obtained from sample testing supports confident decision-making and reduces uncertainty during final specification.

EMI Shielding Gasket Sample Request for Custom Designs

Most high-performance EMI shielding applications require customization. A well-prepared EMI shielding gasket sample request enables manufacturers to tailor:

- Gasket diameter and cross-section

- Material and plating options

- Spring force characteristics

- Forming method for complex grooves

Custom samples allow engineers to validate both performance and manufacturability before committing to volume production.

Product Description: EMI Shielding Gasket Sample Request Service

우리의 EMI shielding gasket sample request service is designed to support engineers and sourcing teams during design validation and supplier qualification.

We provide customized EMI shielding gasket samples that allow you to evaluate fit, force, and shielding effectiveness before final approval.

Key Features:

- Custom sizes and cross-sections available

- Multiple material and plating options

- Samples suitable for EMI, mechanical, and environmental testing

- Engineering support for design optimization

- Fast turnaround for prototype and evaluation samples

By submitting an EMI shielding gasket sample request, you gain early insight into product performance and reduce the risk of costly redesigns.

How to Submit an EMI Shielding Gasket Sample Request

Submitting an EMI shielding gasket sample request is straightforward:

- Share your application requirements and drawings

- Define performance and environmental conditions

- Specify sample quantity and preferred format

- Review engineering recommendations

- Receive samples for testing and evaluation

Our engineering team works closely with you to ensure the sample aligns with your application needs.

Conclusion: Reduce Risk with an EMI Shielding Gasket Sample Request

An EMI shielding gasket sample request is a critical step in selecting the right shielding solution for demanding electronic applications. By testing samples early, engineers can verify performance, ensure proper fit, and make informed decisions with confidence.

Whether you are developing a new product or optimizing an existing design, an EMI shielding gasket sample request helps bridge the gap between design assumptions and real-world performance—saving time, cost, and engineering effort.

Table: EMI Shielding Gasket Sample Request – Purpose and Benefits

| 카테고리 | Description | Value for Engineers & Buyers |

|---|---|---|

| Purpose of Sample Request | Validate EMI shielding performance before final specification | Reduces design uncertainty and project risk |

| When to Request Samples | During prototyping, pre-qualification testing, or supplier evaluation | Prevents late-stage redesigns and delays |

| Supported Gasket Types | Canted coil spring gaskets, spiral spring gaskets, metal EMI gaskets | Enables comparison of multiple shielding solutions |

| 사용자 지정 옵션 | Custom sizes, profiles, cut lengths, or formed gaskets | Ensures accurate fit in real enclosure designs |

| 성능 검증 | EMI attenuation, contact force, compression behavior | Confirms real-world shielding effectiveness |

| Mechanical Evaluation | Fit, installation ease, tolerance compensation | Identifies assembly or groove design issues early |

| 환경 테스트 | Temperature, vibration, cycle life | Verifies long-term reliability |

| Engineering Support | Material and design recommendations during sampling | Improves solution selection accuracy |

| Risk Reduction | Early detection of performance or compatibility issues | Avoids costly production changes |

| Outcome | Approved gasket design ready for specification | Faster transition from prototype to mass production |

다른 사용자도 좋아할 수 있습니다.

-

Custom Canted Coil Spring: Design Considerations and Manufacturing Process

Custom Canted Coil Spring: Design Considerations and Manufacturing Process핑거스트립

직각 차폐 핑거스트립

Custom canted coil springs offer tailored force, deflection, and durability for demanding applications. Learn key design considerations, materials, manufacturing processes, and quality controls for custom canted coil spring solutions. Introduction In today’s high-performance mechanical and electrical systems, standard components often......

-

Loss of Force in Canted Coil Springs: Causes and Solutions

Loss of Force in Canted Coil Springs: Causes and Solutions핑거스트립

직각 차폐 핑거스트립

Loss of force in canted coil springs explained. Learn the root causes, performance impacts, and proven engineering solutions to ensure long-term spring reliability. Introduction Canted coil springs are widely recognized for their ability to deliver near-constant force over a wide......

-

Canted Coil Spring for EMI Shielding

Canted Coil Spring for EMI ShieldingRF/EMI 차폐 나선형 개스킷

한다 나선형 방패

Canted coil spring for EMI shielding provide consistent contact force, superior conductivity, and long service life. Learn how they work, key advantages over fingerstock, material options, installation design, and typical EMI shielding applications. Canted Coil Spring for EMI Shielding Electromagnetic......

-

HANDA RF/EMI Shielding Hastelloy Spiral Gasket for Semiconductor CVD Equipment

HANDA RF/EMI Shielding Hastelloy Spiral Gasket for Semiconductor CVD EquipmentRF/EMI 차폐 나선형 개스킷

한다 나선형 방패

Discover HANDA’s RF/EMI Shielding Spiral Gasket made from premium Hastelloy C-276. Engineered for semiconductor CVD equipment, it delivers exceptional chemical resistance, high-temperature stability, and reliable RF/EMI attenuation for demanding plasma and vacuum process environments. HANDA proudly introduces its latest high-performance......

-

HANDA Spiral EMI Shielding Gaskets Solutions Now Available

HANDA Spiral EMI Shielding Gaskets Solutions Now AvailableRF/EMI 차폐 나선형 개스킷

한다 나선형 방패

Hunan Handa Spiral Spring EMI Shielding Solutions New Partnership Announcement: HANDA Spiral EMI Shielding Gaskets Solutions Now Available.As the demand for reliable electromagnetic interference (EMI) protection continues to grow across electronics, telecommunications, automotive, and aerospace industries, manufacturers are seeking shielding......