Loss of Force in Canted Coil Springs: Causes and Solutions

우리의 캔트 코일 스프링 are engineered to deliver long-term force stability in demanding mechanical, electrical, and EMI shielding applications. Designed to address common issues such as stress relaxation, creep, over-compression, and fatigue-induced force loss, each spring provides reliable performance throughout its service life.

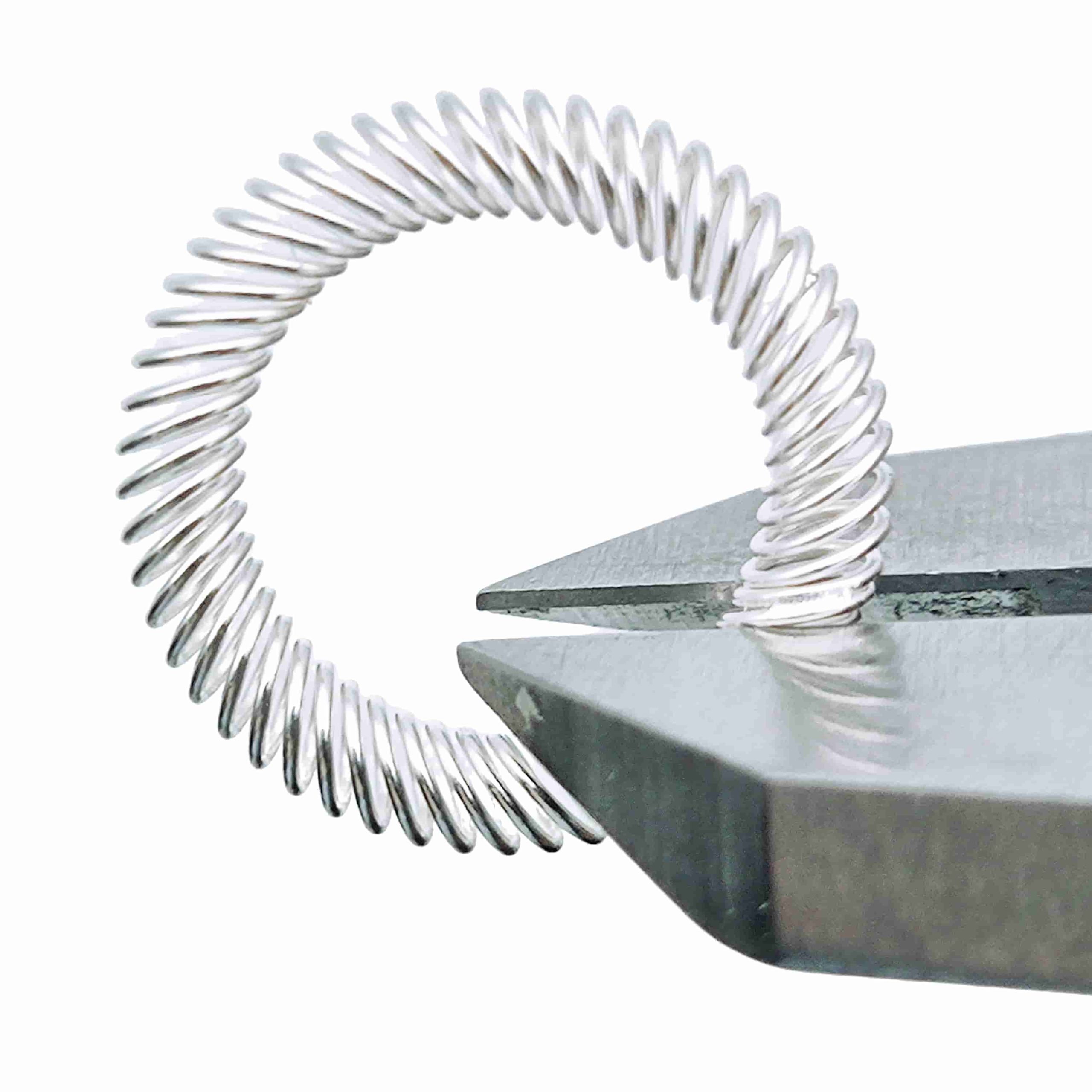

Unlike conventional compression springs, 캔트 코일 스프링 feature angled elliptical coils that enable near-constant force over a wide deflection range. This unique geometry allows the spring to compensate for tolerance variations while maintaining consistent contact or retention force, even after repeated cycling or prolonged static loading.

Designed to Minimize Loss of Force

Loss of force is a critical concern in spring performance. Our canted coil springs are custom-designed to reduce force degradation by controlling operating deflection, optimizing coil geometry, and selecting materials matched to temperature, load, and environmental conditions.

Key design advantages include:

-

Controlled elastic working range to prevent permanent deformation

-

Optimized stress distribution to reduce stress relaxation and creep

-

High resistance to force decay under continuous or cyclic compression

These features ensure stable force output over time, even in high-reliability applications.

Consistent Performance Across Wide Deflection Ranges

의 주요 이점 중 하나는 캔트 코일 스프링 is their ability to maintain consistent force across repeated compression cycles. This makes them ideal for applications where traditional springs experience rapid force loss.

Benefits include:

-

Reliable holding and retention force

-

Stable electrical contact pressure

-

Reduced performance drift over product lifetime

This consistency improves system reliability and reduces maintenance or replacement costs.

Material Options for Temperature and Environment Control

Material selection plays a critical role in preventing force loss. Our canted coil springs are available in a wide range of materials to ensure optimal performance under specific operating conditions.

Available materials include:

-

Stainless steel for general mechanical applications

-

Copper alloys for enhanced electrical conductivity

-

Nickel-based alloys such as Inconel and Hastelloy for high-temperature or corrosive environments

Optional surface treatments and platings help further reduce oxidation, corrosion, and wear-related force degradation.

Precision Fit and Groove Compatibility

Improper groove design is a common contributor to force loss. Our 캔트 코일 스프링 are manufactured with precise dimensional control to ensure proper groove fit and even load distribution.

This results in:

-

Reduced wear and surface damage

-

Prevention of over-compression

-

Improved long-term force stability

Engineering support is available to assist with groove design optimization.

Validated Through Testing and Quality Control

Each canted coil spring is manufactured under strict quality control standards and validated through performance testing, including:

-

Load–deflection verification

-

Stress relaxation evaluation

-

Fatigue life testing

-

Environmental performance assessment

These measures ensure consistent force output and reliable operation throughout the intended service life.

일반적인 애플리케이션

우리의 캔트 코일 스프링 are widely used in:

-

Mechanical latching and locking mechanisms

-

Electrical contacts and grounding interfaces

-

EMI shielding assemblies

-

Precision connectors and enclosures

-

Equipment requiring repeated assembly and disassembly

요약

By combining optimized geometry, application-specific material selection, and precise manufacturing, our 캔트 코일 스프링 effectively minimize loss of force while delivering reliable long-term performance. Whether used for mechanical retention, electrical conductivity, or EMI shielding, these springs provide a proven solution for applications where force stability is critical.

Loss of force in canted coil springs explained. Learn the root causes, performance impacts, and proven engineering solutions to ensure long-term spring reliability.

소개

캔트 코일 스프링 are widely recognized for their ability to deliver near-constant force over a wide deflection range. This makes 캔트 코일 스프링 an ideal choice for applications involving repeated cycling, tolerance compensation, latching mechanisms, and EMI shielding. However, under certain conditions, a loss of force may occur over time, compromising system performance and reliability.

Loss of force is one of the most critical performance issues engineers encounter when designing with canted coil springs. If not properly understood and addressed, it can lead to poor contact pressure, mechanical instability, electrical discontinuity, or even complete system failure.

This article provides a comprehensive analysis of loss of force in canted coil springs, including its primary causes, contributing factors, performance consequences, and proven engineering solutions. By understanding these mechanisms, designers and manufacturers can significantly extend service life and prevent premature failures.

Understanding Force Characteristics of Canted Coil Springs

Unlike traditional compression springs, 캔트 코일 스프링 are constructed with angled, elliptical coils. This geometry allows the spring to compress smoothly while maintaining relatively stable force output across its working range.

Key force-related characteristics include:

- Near-constant force across a wide deflection range

- Lower stress concentration compared to conventional springs

- Improved fatigue resistance

- Stable mechanical and electrical contact force

Despite these advantages, force stability is not unlimited. Environmental conditions, material behavior, and design choices can all influence long-term force retention.

What Is Loss of Force in Canted Coil Springs?

Loss of force refers to a reduction in the spring’s ability to deliver its specified load at a given deflection. In canted coil springs, this phenomenon often develops gradually rather than catastrophically.

Common symptoms include:

- Reduced holding or retention capability

- Decreased contact pressure in electrical or EMI applications

- Increased vibration or mechanical looseness

- Inconsistent system performance over time

Understanding the underlying causes is essential for effective prevention.

Primary Causes of Loss of Force in Canted Coil Springs

Loss of Force in Canted Coil Springs – Causes and Solutions Overview

| Cause of Force Loss | Description | Impact on Performance | Engineering Solutions | Design Recommendations |

|---|---|---|---|---|

| Stress Relaxation | Long-term static compression causes internal stress reduction in the spring material | Gradual reduction in spring force and holding capability | Use creep-resistant materials; limit continuous compression | Design operating deflection within 30–70% of total range |

| Material Creep | Atomic movement under sustained load, accelerated by temperature | Permanent force loss over time | Select high-performance alloys (Inconel, Hastelloy) | Match material choice to load and temperature conditions |

| Excessive Temperature | Elevated temperatures reduce material yield strength | Accelerated force decay and deformation | Use heat-resistant materials; reduce static load | Perform thermal analysis during design stage |

| Over-Compression | Compression beyond elastic limit due to poor groove design | Permanent deformation and loss of force | Add compression stops; redesign groove depth | Validate groove dimensions and tolerance stack-up |

| Improper Material Selection | Material not suitable for environment or load | Early force loss and reduced service life | Use application-specific materials and platings | Define environment, load, and lifespan requirements early |

| Fatigue Damage | High-cycle loading causes microstructural degradation | Gradual force degradation or spring failure | Optimize coil geometry; improve surface finish | Specify fatigue life requirements and testing |

| Wear and Abrasion | Friction between spring and groove surfaces | Reduced force due to geometry change | Smooth groove finish; rounded edges | Recommended groove Ra ≤ 0.8 μm |

| Corrosion | Chemical or environmental attack on spring wire | Reduced cross-section and weakened force output | Use corrosion-resistant alloys and coatings | Consider salt spray or chemical exposure testing |

| Poor Groove Design | Uneven load distribution and localized stress | Inconsistent force and accelerated wear | Co-design spring and groove geometry | Avoid sharp edges and insufficient groove width |

| Inadequate Testing | Performance issues not detected before production | Unexpected force loss in field use | Conduct relaxation and fatigue testing | Validate design with accelerated life testing |

1. Stress Relaxation and Material Creep

Stress relaxation is one of the most common causes of force loss in 캔트 코일 스프링, especially in static or semi-static applications.

How it occurs:

- The spring is held at a constant deflection for extended periods

- Elevated temperatures accelerate atomic movement within the material

- Internal stresses gradually decrease, reducing output force

Contributing factors:

- High operating temperatures

- Continuous compression

- Inadequate material selection

2. Excessive Operating Temperature

Temperature has a direct impact on the mechanical properties of spring materials. As temperature increases, yield strength decreases, making force loss more likely.

Effects on canted coil springs:

- Accelerated stress relaxation

- Reduced elastic modulus

- Increased permanent deformation risk

Applications in automotive, aerospace, and semiconductor equipment often require careful thermal analysis to avoid force degradation.

3. Over-Compression Beyond Design Limits

Although 캔트 코일 스프링 tolerate wide deflection ranges, exceeding their designed working deflection can cause permanent deformation.

Typical causes:

- Incorrect groove depth

- Poor tolerance stack-up

- Lack of compression stop features

Once plastic deformation occurs, force recovery is no longer possible.

4. Improper Material Selection

Material choice plays a crucial role in force retention. Selecting a material without adequate creep resistance or temperature capability can result in early force loss.

Common issues include:

- Using standard stainless steel in high-temperature environments

- Insufficient alloy strength for continuous load applications

- Ignoring environmental exposure factors

5. Fatigue-Induced Force Degradation

While fatigue failure often results in fracture, it can also manifest as gradual force loss due to microstructural damage.

Causes include:

- High-cycle compression beyond endurance limits

- Surface imperfections acting as stress risers

- Uneven load distribution

Fatigue-related force loss is particularly relevant in applications involving frequent insertion and removal cycles.

6. Wear and Surface Damage

Mechanical wear between the spring and mating groove can alter coil geometry over time, leading to reduced force output.

Contributing factors:

- Rough groove surface finish

- Sharp edges

- Excessive lateral movement

Wear-related force loss is often overlooked during initial design.

7. Corrosion and Environmental Effects

Corrosion reduces the effective cross-section of the spring wire, weakening its ability to generate force.

Common environments include:

- High humidity

- Salt fog

- Chemical exposure

Without proper material or plating protection, force loss may occur much earlier than expected.

Impact of Force Loss on System Performance

Loss of force in 캔트 코일 스프링 can have cascading effects across an entire system:

- Reduced mechanical retention or locking performance

- Intermittent electrical contact or grounding failure

- Degraded EMI shielding effectiveness

- Increased noise, vibration, and wear

In high-reliability applications, even minor force loss can result in unacceptable performance variation.

Engineering Solutions to Prevent Loss of Force

1. Optimize Operating Deflection

Designing the spring to operate within a safe deflection range is one of the most effective prevention methods.

Best practices include:

- Operating within 30–70% of total available deflection

- Avoiding continuous maximum compression

- Incorporating compression stops where necessary

2. Select High-Performance Materials

Material selection should be based on load, temperature, environment, and required service life.

Common material options:

- Stainless steel for general-purpose applications

- Copper alloys for electrical performance

- Nickel-based alloys (Inconel, Hastelloy) for high-temperature and corrosive environments

Proper material choice significantly improves force stability.

3. Control Temperature Exposure

Thermal management strategies can dramatically reduce stress relaxation effects.

Solutions include:

- Heat-resistant alloys

- Thermal isolation features

- Reduced static compression at elevated temperatures

4. Precision Groove Design

Correct groove geometry ensures even load distribution and prevents over-compression.

Design considerations:

- Proper groove width and depth

- Smooth surface finish

- Rounded edges to reduce wear

Groove design and spring design should always be developed together.

5. Improve Surface Finish and Coatings

Surface treatments reduce friction, wear, and corrosion.

Options include:

- Polished wire finishes

- Protective or conductive platings (tin, silver, gold)

- Anti-corrosion coatings

These measures help maintain consistent force over time.

6. Validate Through Testing

Testing is essential to confirm long-term force retention.

Recommended tests:

- Load–deflection testing

- Accelerated stress relaxation testing

- Fatigue life testing

- Environmental exposure testing

Product Description: High-Performance Canted Coil Springs

우리의 캔트 코일 스프링 are engineered to deliver stable force, long fatigue life, and reliable performance across demanding mechanical and electrical applications. Each spring is custom-designed to minimize force loss through optimized geometry, precise material selection, and controlled manufacturing processes.

주요 기능

- Near-constant force over a wide deflection range

- Excellent resistance to stress relaxation and creep

- High fatigue durability for repeated cycling

- Precision fit for custom groove designs

- Optional conductive and protective platings

머티리얼 옵션

- 스테인리스 스틸

- Copper alloys

- Nickel-based alloys for extreme environments

애플리케이션

- Mechanical latching and locking systems

- Electrical contacts and grounding

- EMI shielding assemblies

- Precision connectors and enclosures

Our canted coil springs are designed to maintain force integrity throughout their service life, reducing maintenance costs and improving system reliability.

Quality Control and Performance Assurance

Every canted coil spring undergoes rigorous quality control, including:

- Dimensional inspection

- Force and deflection verification

- Fatigue and relaxation evaluation

- Environmental performance testing

This ensures consistent performance and long-term force stability.

결론

Loss of force in 캔트 코일 스프링 is a critical issue that can significantly impact mechanical and electrical system performance. While causes such as stress relaxation, temperature exposure, over-compression, and material limitations are common, they are largely preventable through informed design and proper engineering practices.

By optimizing deflection, selecting appropriate materials, controlling environmental exposure, and validating designs through testing, engineers can effectively eliminate premature force loss and fully realize the benefits of canted coil springs.

When correctly specified and applied, 캔트 코일 스프링 provide reliable, long-term force performance for even the most demanding applications.

For more info.,please email to : sale01@handashielding.com

다른 사용자도 좋아할 수 있습니다.

-

Canted Coil Spring for EMI Shielding

Canted Coil Spring for EMI ShieldingRF/EMI 차폐 나선형 개스킷

한다 나선형 방패

Canted coil spring for EMI shielding provide consistent contact force, superior conductivity, and long service life. Learn how they work, key advantages over fingerstock, material options, installation design, and typical EMI shielding applications. Canted Coil Spring for EMI Shielding Electromagnetic......

-

HANDA RF/EMI Shielding Hastelloy Spiral Gasket for Semiconductor CVD Equipment

HANDA RF/EMI Shielding Hastelloy Spiral Gasket for Semiconductor CVD EquipmentRF/EMI 차폐 나선형 개스킷

한다 나선형 방패

Discover HANDA’s RF/EMI Shielding Spiral Gasket made from premium Hastelloy C-276. Engineered for semiconductor CVD equipment, it delivers exceptional chemical resistance, high-temperature stability, and reliable RF/EMI attenuation for demanding plasma and vacuum process environments. HANDA proudly introduces its latest high-performance......

-

HANDA Spiral EMI Shielding Gaskets Solutions Now Available

HANDA Spiral EMI Shielding Gaskets Solutions Now AvailableRF/EMI 차폐 나선형 개스킷

한다 나선형 방패

Hunan Handa Spiral Spring EMI Shielding Solutions New Partnership Announcement: HANDA Spiral EMI Shielding Gaskets Solutions Now Available.As the demand for reliable electromagnetic interference (EMI) protection continues to grow across electronics, telecommunications, automotive, and aerospace industries, manufacturers are seeking shielding......

-

High-Performance Conductive Fabric for EMI Shielding in Electronics and Communication Equipment

High-Performance Conductive Fabric for EMI Shielding in Electronics and Communication EquipmentEMI 테이프, EMC 포일, 전도성 직물 및 반전도성 부직포

Conductive cloth/fabrics

1. Introduction to Conductive Fabric2. Key Performance Advantages3. Applications in Electronics and Communication3.1 Consumer and Industrial Electronics3.2 5G and Telecommunication Systems3.3 Automotive Electronics3.4 Aerospace and Defense3.5 Wearable and Medical Devices4. Technical Specifications5. Why Choose Handa Shielding7. Conclusion 1. Introduction to......

-

Electrical Conducting Springs: The Core Component for Efficient Connections in the Power Industry

Electrical Conducting Springs: The Core Component for Efficient Connections in the Power Industry한다 캔트 코일 스프링

전기 전도성 스프링

In high-voltage switchgear, GIS (Gas-Insulated Switchgear), and power transmission and distribution systems, electrical conducting springs have emerged as indispensable key conductive components in modern power equipment, thanks to their unique structural design and superior electrical performance. Hunan Handa Electronics Technology......