6 Canted Coil Spring Groove Design Mistakes: Common Errors and How to Avoid Them

Learn the most common canted coil spring groove design mistakes and how to avoid them. Improve performance, reliability, and service life with proper groove design.

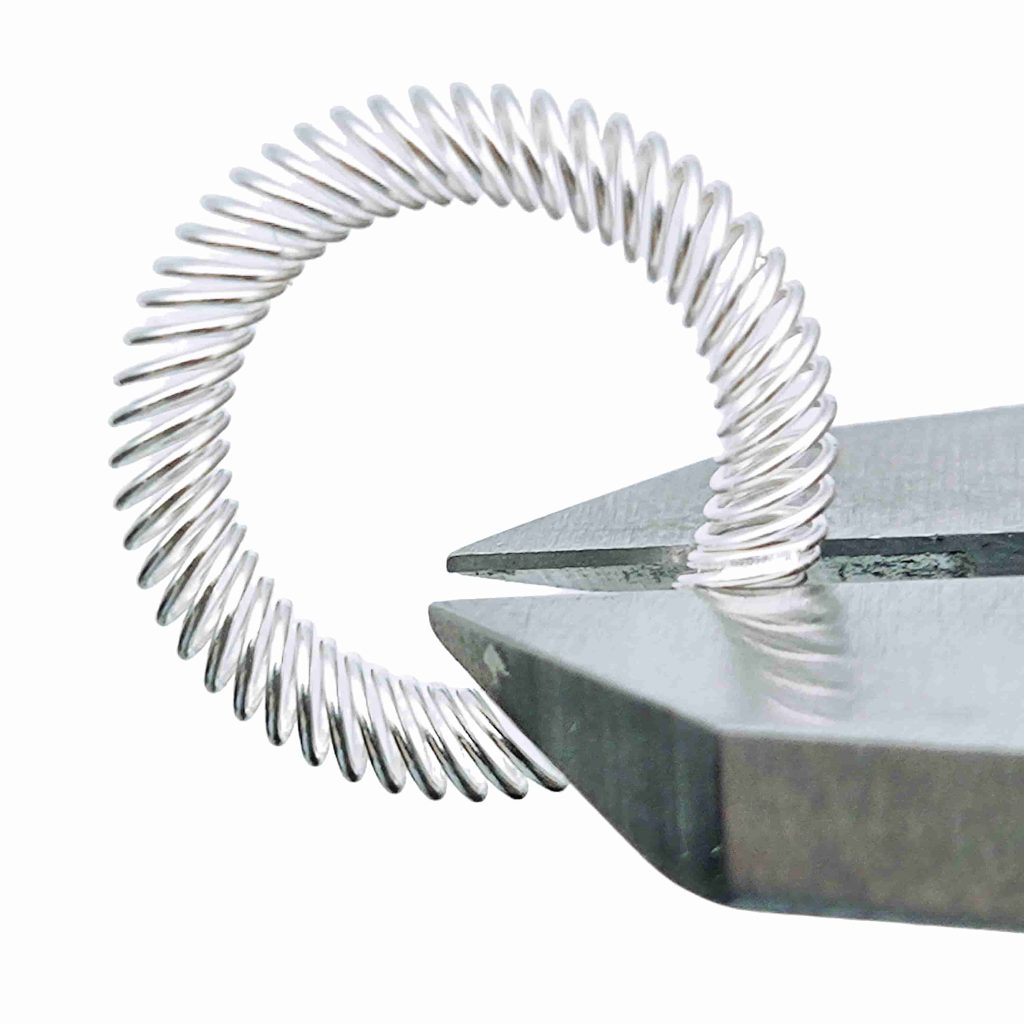

캔트 코일 스프링 are widely used in demanding applications such as automotive connectors, medical devices, aerospace systems, and EMI shielding assemblies. Their ability to deliver consistent force over a wide deflection range makes them superior to traditional spring designs in many cases.

However, even the best canted coil spring can fail to perform as intended if the groove design is incorrect. In fact, groove-related issues are among the most common causes of premature spring failure, inconsistent load, and assembly problems.

This article explores the most common canted coil spring groove design mistakes, explains why they occur, and provides practical guidance to help engineers avoid costly design errors.

Why Groove Design Matters for Canted Coil Springs

Unlike conventional compression springs, canted coil springs rely on controlled interaction between the spring and its groove. The groove geometry directly affects:

- Spring deflection behavior

- Load consistency

- Retention and stability

- Wear and service life

- Ease of installation

A poorly designed groove can negate the advantages of a canted coil spring, leading to uneven force distribution, excessive wear, or spring damage.

Common Canted Coil Spring Groove Design Mistakes

1. Incorrect Groove Width

One of the most frequent mistakes is specifying a groove width that is either too narrow or too wide.

- Too narrow:

- Restricts spring movement

- Causes coil binding

- Leads to uneven stress and early fatigue

- Too wide:

- Allows excessive lateral movement

- Reduces load stability

- Increases risk of spring dislodgement

Best practice:

Groove width should be carefully matched to the spring cross-section, allowing controlled movement without excessive clearance.

2. Improper Groove Depth

Groove depth directly affects how much the canted coil spring can deflect.

Common issues include:

- Groove too shallow → insufficient deflection, reduced force range

- Groove too deep → over-deflection, permanent deformation, or loss of force

Design tip:

The groove depth must accommodate the spring’s working deflection while preventing over-compression beyond its elastic limit.

3. Sharp Edges and Poor Surface Finish

Sharp corners and rough groove surfaces can severely damage a canted coil spring over time.

Potential problems:

- Abrasion of spring coils

- Increased friction

- Accelerated wear

- Reduced fatigue life

솔루션:

- Use chamfered or radiused edges

- Specify a smooth surface finish, especially in dynamic or high-cycle applications

4. Ignoring Groove Shape Selection

Not all grooves are created equal. Choosing the wrong groove profile can compromise performance.

Common groove shapes include:

- Rectangular grooves

- Dovetail grooves

- V-shaped grooves

- Tapered grooves

Each has specific advantages depending on load direction, retention requirements, and assembly method.

Mistake:

Using a simple rectangular groove when retention or vibration resistance is required.

5. Overlooking Tolerance Stack-Up

Even a well-designed groove can fail if tolerances are not properly controlled.

Issues caused by poor tolerance management:

- Inconsistent spring preload

- Assembly variability

- Performance differences between units

Recommendation:

Account for manufacturing tolerances of both the groove and the canted coil spring during the design phase.

6. Not Considering Operating Environment

Environmental factors are often overlooked in groove design.

Common oversights:

- Thermal expansion at high temperatures

- Corrosion in humid or chemical environments

- Debris accumulation in open grooves

Best practice:

Design groove dimensions and clearances based on the actual operating conditions, not just nominal values.

Common Groove Design Mistakes and Their Impact

| Groove Design Mistake | Potential Impact | Resulting Problem |

|---|---|---|

| Groove too narrow | Restricted movement | Coil binding, fatigue |

| Groove too wide | Excessive play | Inconsistent load |

| Insufficient depth | Limited deflection | Reduced performance |

| Excessive depth | Over-compression | Permanent deformation |

| Sharp edges | High wear | Shortened service life |

| Poor tolerance control | Assembly variation | Unstable performance |

Best Practices for Canted Coil Spring Groove Design

To avoid these common mistakes, engineers should follow several key guidelines:

- Match groove dimensions precisely to the spring design

- Select groove shapes based on retention and load requirements

- Use smooth finishes and rounded edges

- Account for tolerances and environmental factors

- Collaborate with experienced canted coil spring manufacturers early in the design process

Early consultation can significantly reduce redesign costs and improve long-term reliability.

Why Manufacturer Expertise Matters

Groove design should never be treated as an afterthought. Experienced canted coil spring manufacturers provide valuable engineering insight, including:

- Groove optimization for specific spring geometries

- Material recommendations based on environment

- Prototyping and validation support

- Application-specific design adjustments

Working with a knowledgeable supplier helps ensure that the spring and groove function as a complete, optimized system.

결론

Canted coil springs offer exceptional performance—but only when paired with proper groove design. Mistakes such as incorrect groove width, depth, shape, or surface finish can lead to performance issues, reduced lifespan, and costly failures.

By understanding and avoiding these common canted coil spring groove design mistakes, engineers can fully leverage the advantages of this advanced spring technology. Careful design, proper tolerancing, and collaboration with experienced manufacturers are the keys to long-term success.