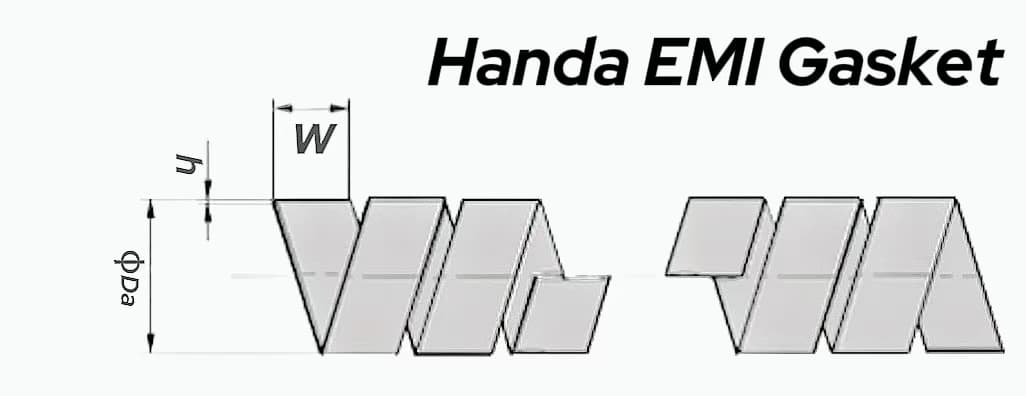

RF/EMI Shield Spiral Gasket

Handa Shielding provides premium EMI/RFI shielding solutions, including EMI shielding gaskets, custom O-rings, plated shields, RF gasketing, and more for various industries. We are Manufacturing Corporation for reliable, custom sealing solutions.

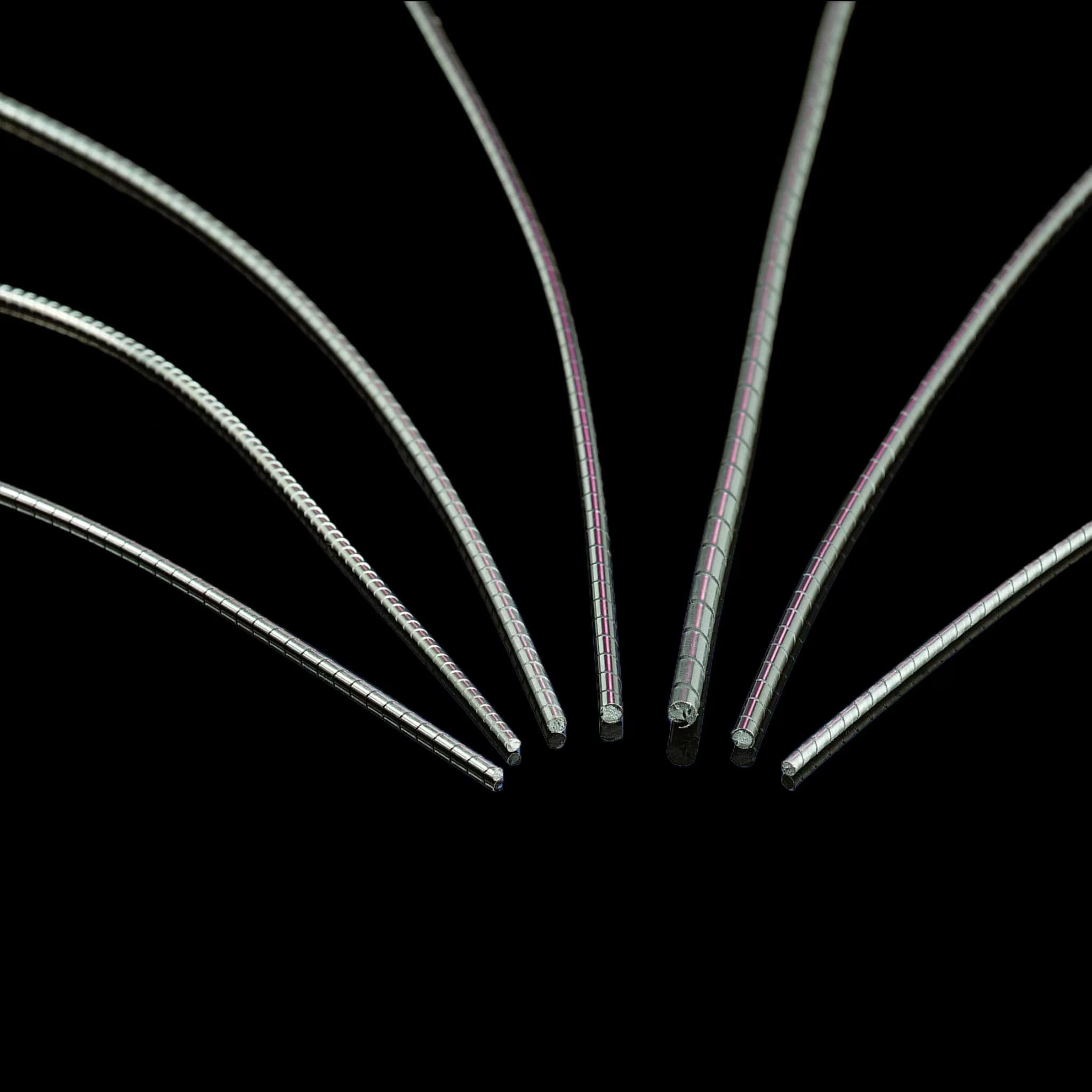

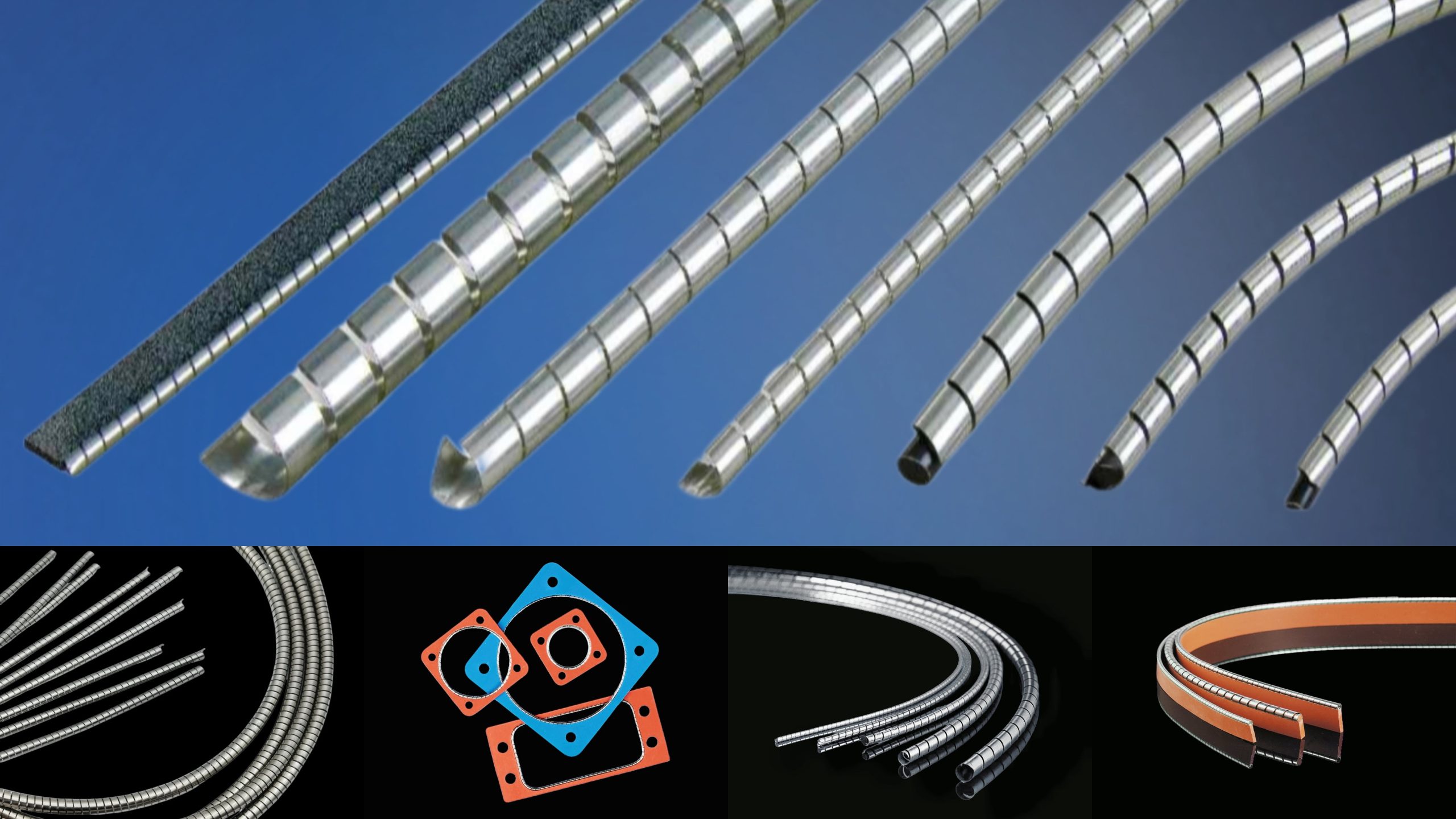

Spiral EMI Shielding Gasket stands as an exemplary shielding material, tailored for sensitive equipment that necessitates unparalleled electromagnetic shielding performance.

The Gasket is crafted from high-elastic Sn/Ni plated metals and offers flexibility, resilience, and exceptional shielding efficiency. Its Seamless integration ensures a robust barrier against EMI & RFI for diverse equipment, such as semiconductor manufacturing equipment (plasma etching equipment), precision medical equipment, telecommunications equipment, etc.

All RF/EMI Shield Spiral Gasket

Groove Mounted Series

Compression Force

Shield Spiral Gaskets are obtainable in three distinct resiliencies (as illustrated below). The optimum compression of the gasket amounts to 25% of the diameter of the spiral.

Since the force necessary to compress the gasket is a function of the cube of the thickness of the stainless steel ribbon, the compression forces presented are approximate.

We can also customize the product to meet specific compression force requirements. Click here contact us!

Standard Force (“S” Series)

| “S” Series | SBS | SBN | SSN | STA | |

|---|---|---|---|---|---|

| Ribbon Strip | Sn-plated BeCu | Ni-plated BeCu | Stainless Steel | Titanium alloy | |

| Strip | Material | Beryllium Copper C17200 | 304H | TA1 | |

| Electrical Conductivity | 17~28 %IACS | – | – | ||

| Compression Force

(OD 3.2mm, 25% Comp, Kgf/in.) |

4.8 ±15% | 4.8 ±15% | 6.5 ±15% | – | |

| String Outer Diameter (OD) | 1.0 ~ 12.0 mm | ||||

Others (“M”, “L” Series)

* Strip materials are the same as standard force’s.

| Series | Medium Force(“M”Series) | Low Force(“L”Series) | ||||

|---|---|---|---|---|---|---|

| MBS | MBN | MSN | LBS | LBN | LSN | |

| Strip Material | Sn-plated BeCu | Ni-plated BeCu | Stainless Steel | Sn-plated BeCu | Ni-plated BeCu | Stainless Steel |

| Compression Force

(OD 3.2mm,25%Comp,Kgf/in.) |

2.0±15% | 2.0±15% | 2.7±15% | 0.4±15% | 0.4±15% | 0.6±15% |

| String Outer Diameter(OD) | 1.0~10.0 mm | 2.3~10.0 mm | ||||

Product Support

How to choose a proper P/N

* Options available by ribbon strip material, force, inner cord material, O-Ring, etc.

Splicing Options: Spiral has created three standard options to treat the splicing of material in our spool selection.

* If over-compression of the gasket is not a concern or problem,to keep costs low, we recommend you omit the cord usually used in the spiral.

| Options | Codes |

|---|---|

| Product Series | S: Shield Spiral Gasket |

| Force | S: Standard Force, M: Medium Force, L: Low Force |

| Strip Material | BS: Sn plated BeCu,BN: Ni plated BeCu, SN: Stainless Steel,SNS: Sn plated Stainless Steel,SNN: Ni plated Stainless SteelTA: Titanium alloy |

| String OD (Ø) | 008~150 (0.8~15.0mm) |

| Inner Cord (Core) | W: Cordless,A: Silicone rubber solid,T: Silicone rubber tube,F: Silicone foam If it is hollow, mark ‘H’,For example ‘AH’ represents the material of hollow core Silicone rubber solid |

| O-Ring ID* | R: O-Ring Inner Diameter(mm), * String type unless otherwise indicated |

| Elastomer wall thickness* | t: Elastomer wall thickness(mm) |

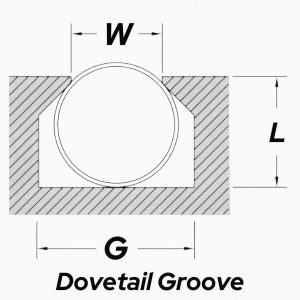

Recommended Groove Size

The following is a drawing for size reference.

| String OD [mm] | Groove Size [mm] | ||

|---|---|---|---|

| Depth(L)

+0.05 /-0 (mm) |

Width(G)

+0.18 / -0.13 (mm) |

Width(W)

+0 / -0.05 (mm) |

|

| 0.86 ± 0.05 | 0.58 | 1.17 | 0.84 |

| 1.19 ± 0.05 | 0.89 | 1.60 | 1.14 |

| 1.60 ± 0.08 | 1.17 | 2.39 | 1.52 |

| 1.78 ± 0.08 | 1.35 | 2.39 | 1.70 |

| 1.98 ± 0.08 | 1.50 | 2.77 | 1.91 |

| 2.39 ± 0.10 | 1.78 | 3.18 | 2.29 |

| 2.62 ± 0.10 | 1.96 | 3.58 | 2.51 |

| 2.77 ± 0.10 | 2.08 | 3.96 | 2.67 |

| 3.18 ± 0.10 | 2.39 | 4.34 | 3.07 |

| String OD [mm] | Groove Size [mm] | ||

|---|---|---|---|

| Depth(L)

+0.05 /-0 (mm) |

Width(G)

+0.18 / -0.13 (mm) |

Width(W)

+0 / -0.05 (mm) |

|

| 3.53 ± 0.13 | 2.64 | 4.75 | 3.40 |

| 3.58 ± 0.13 | 2.67 | 4.75 | 3.45 |

| 4.37 ± 0.13 | 3.25 | 5.94 | 4.19 |

| 4.75 ± 0.15 | 3.56 | 6.35 | 4.60 |

| 6.35 ± 0.18 | 4.70 | 8.71 | 6.10 |

| 7.92 ± 0.23 | 5.94 | 10.72 | 7.62 |

| 9.53 ± 0.28 | 7.11 | 12.70 | 9.25 |

| 12.70 ± 0.38 | 9.53 | 16.66 | 12.32 |

| custom | |||

Custom Manufacturing

Custom Shield Spiral Gasket

We can manufacture Shield Spiral Gasket in any size diameter, from 0.8mm up to approximately 50.0mm. The functional length of the part may be short at very large diameters. Please contact us with your requirements.

If you have specific Spiral Gasket product customization needs,

it is best to contact the Handa Shielding supplier or manufacturer directly, who can provide detailed information about customization services, product options and pricing. This will ensure you get the best solution for your needs.

RF/EMI Shield Spiral Gasket Manufacturing

If you are looking for top-tier EMI spiral shielding gasket manufacturers with industry-leading expertise, you have come to the right place. Our team consists of experienced manufacturing technicians and electromagnetic compatibility engineering experts who are committed to developing the perfect shielding solutions to meet your specific application requirements. Our specialists can produce spiral EMI gaskets in various diameters (1.6mm to 15mm), materials, and configurations using advanced cold and hot forming processes.

An additional advantage of partnering with Handa Shielding is that we maintain extensive inventory of multiple conductive alloys including stainless steel, beryllium copper, Titanium alloy, Weak magnetic stainless steel, and specialized elastomer materials. This advantage allows us to rapidly develop prototypes and pre-production samples in a highly cost-effective manner, ensuring your EMI shielding requirements are met with both precision and efficiency while significantly reducing your development timeline.

Materials

We also offer a variety of treatment and finishing options for custom Spiral made from standard or specialty materials. Certifications of conformance for geometric tolerances for stock Spiral are available upon request. Material certifications are available for custom spiral.

Finishes

Our Spiral Gaskets can be manufactured with a selection of commonly requested or specialty finishes.

Ordering Information

Shield Spiral Gasket is sold by the foot and typically packaged on spools except in small quantities.

It can also be ordered cut-to-length in specific sizes at a low cost, or you can cut it yourself using a sharp pair of scissors.

Not all configurations are stock items. Contact us for availability. Custom o-rings are also available.