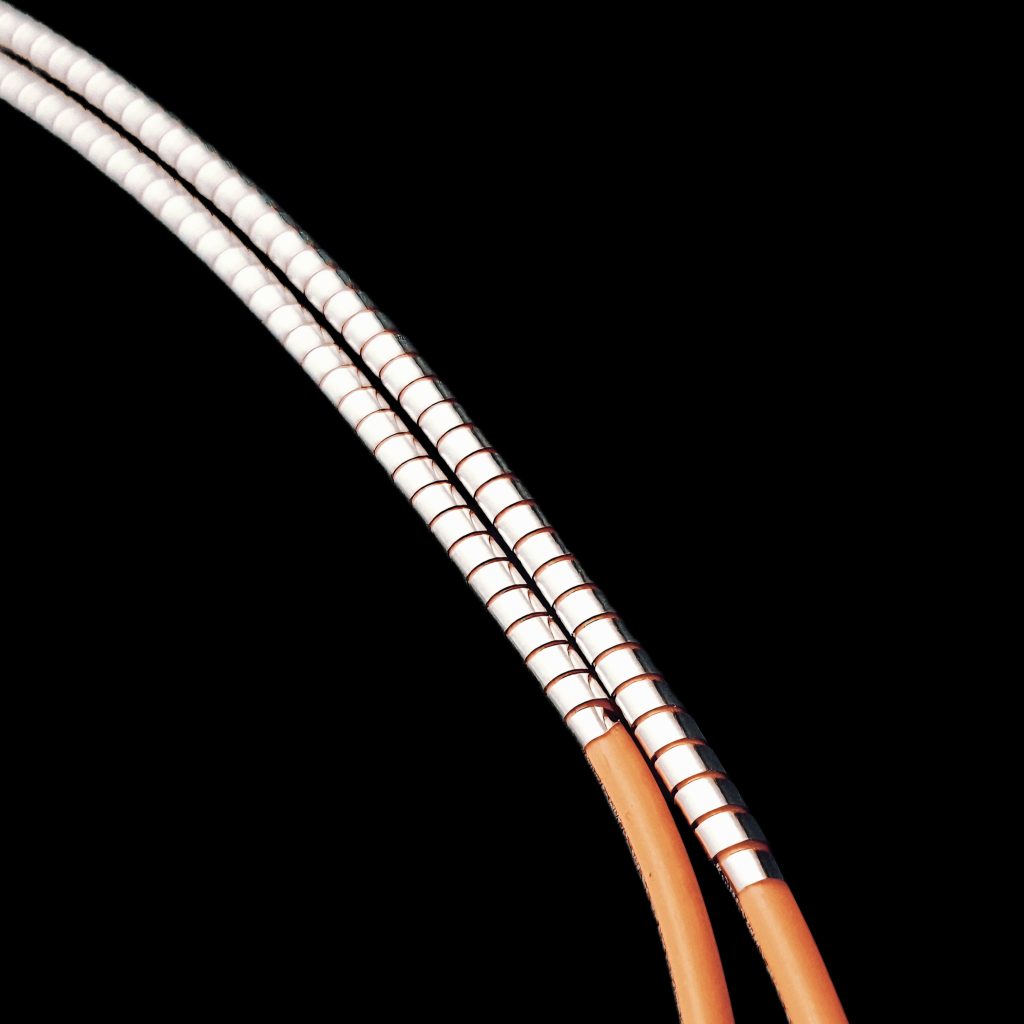

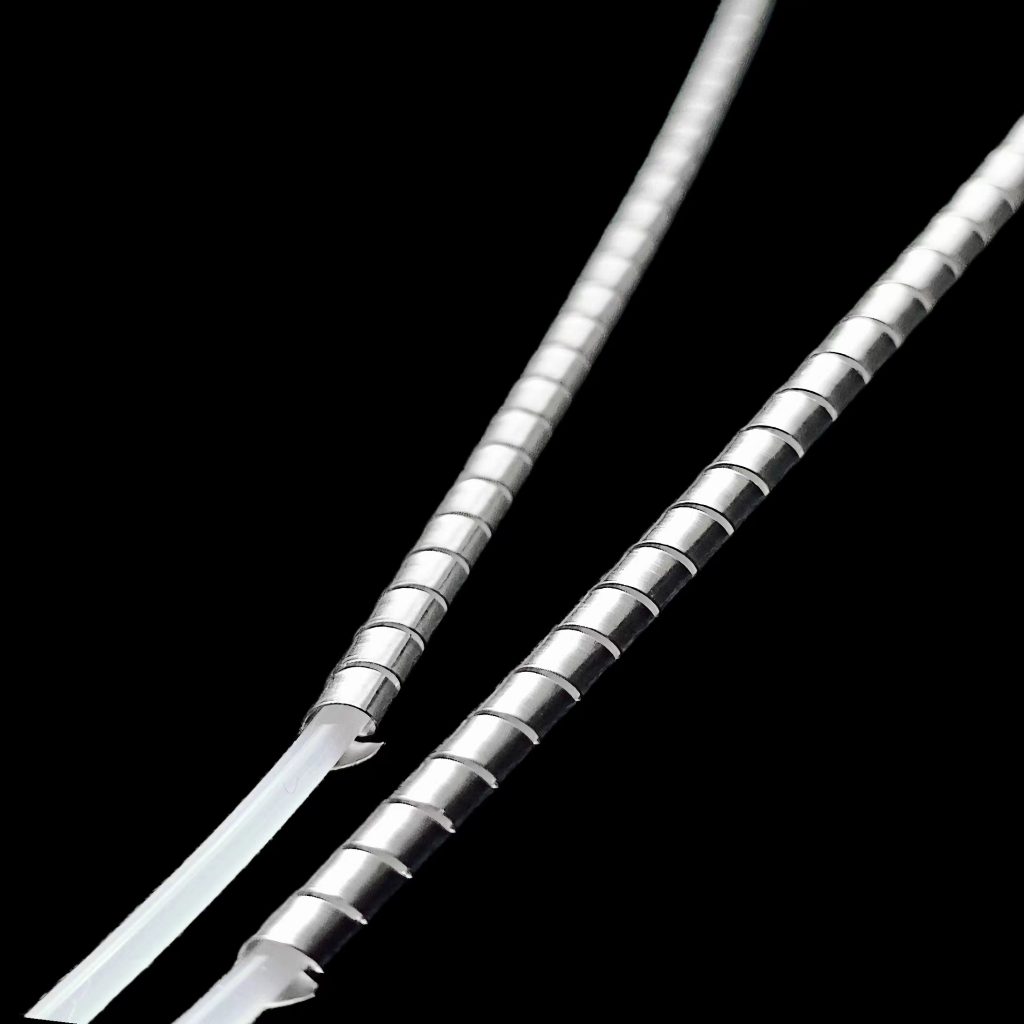

Design and Advantages of Stainless Steel EMI Shielding Spiral Tubes with Silicone Cores

Stainless steel electromagnetic interference (EMI) shielding spiral tubes

with silicone cores

Table of Contents

Stainless steel electromagnetic interference (EMI) shielding spiral tubes with silicone cores combine the excellent shielding properties of stainless steel with the sealing and protective qualities of silicone. This design offers a powerful solution for applications requiring both electromagnetic shielding and environmental sealing. These tubes are particularly valuable in industries where high levels of electromagnetic compatibility (EMC) and environmental protection are essential. Below is an in-depth look at the main features and benefits of these advanced components.

1. Dual Protection: EMI Shielding and Environmental Sealing

One of the primary advantages of stainless steel EMI shielding spiral tubes with silicone cores is their dual functionality. The stainless steel tube itself offers excellent EMI shielding, while the silicone core enhances the environmental sealing properties. This combined protection makes spiral tubes with silicone cores ideal for environments where both electromagnetic interference and external contaminants (like dust, water, or chemicals) pose a threat to sensitive electronic devices.

- Electromagnetic Shielding: Stainless steel is a high-conductivity material that effectively reflects and absorbs electromagnetic waves. Its metallic structure enables the spiral tubes with silicone cores to act as a barrier, preventing unwanted electromagnetic interference from penetrating sensitive components. Stainless steel is particularly effective in the shielding of high-frequency electromagnetic radiation, such as radio-frequency interference (RFI) or microwave signals, which can disrupt the performance of electronic devices.

- Environmental Sealing: The silicone core significantly enhances the sealing capabilities of the EMI shielding spiral tube. Silicone is known for its excellent resistance to moisture, dust, and even some corrosive chemicals. It can prevent water ingress, which could lead to short circuits or corrosion of sensitive electronic parts. This makes the tube suitable for industries such as automotive, aerospace, and medical devices, where the protection of electronics from environmental contaminants is crucial.

This dual function makes these tubes indispensable in applications requiring both high EMI shielding performance and reliable environmental sealing.

2. Flexibility and Adaptability

One of the most remarkable features of stainless steel EMI shielding spiral tubes with silicone cores is their flexibility. The silicone core contributes to the tube’s flexibility, enabling it to adapt to various interface shapes and sizes. This adaptability ensures that the tube can be installed in a wide range of environments, making it ideal for complex or irregular installations.

- Flexible Design: The silicone core allows the tube to be compressed or expanded to fit different shapes and sizes. Whether you need to fit the tube into a tight or irregularly shaped space, the flexibility of the silicone ensures a snug fit, contributing to a reliable seal. This flexibility also makes the tube easier to install, even in challenging locations where rigid materials might not fit as effectively.

- Vibration Resistance: In many industrial and consumer electronic applications, devices experience vibrations from movement or operational processes. The silicone core helps to absorb these vibrations, maintaining a tight seal and preventing any loosening of the tube. This feature is particularly important in applications like automotive and aerospace electronics, where constant vibrations are common.

- Thermal Expansion: Thermal expansion and contraction are common in devices that undergo temperature fluctuations. Silicone’s inherent flexibility allows the tube to maintain its integrity even as materials expand or contract due to heat or cold, ensuring that the sealing function remains effective under varying temperature conditions.

This flexibility and adaptability enhance the reliability and performance of the EMI shielding spiral tube in a wide range of conditions.

3. Excellent Environmental Adaptability

Silicone is known for its exceptional environmental resilience. When paired with stainless steel, the combination offers excellent protection against temperature extremes, aging, chemicals, and moisture. The environmental properties of this hybrid design make the spiral tubes with silicone cores well-suited for use in harsh or demanding environments where other materials might fail.

- Temperature Resistance: Silicone can withstand a wide range of temperatures, from -50°C to 250°C, without losing its mechanical properties. This temperature stability is critical in applications such as automotive engines, aerospace, and industrial machinery, where components may be exposed to extreme heat or cold. The silicone core allows the tube to function optimally in both high-heat and low-temperature environments, ensuring that the sealing properties remain intact.

- Chemical Resistance: Silicone also has excellent resistance to a variety of chemicals, including oils, fuels, solvents, and other corrosive substances. This makes the stainless steel EMI shielding spiral tube with silicone core ideal for use in chemical plants, marine environments, or other industries where the components might be exposed to aggressive chemicals. The silicone core prevents chemical degradation, maintaining the tube’s sealing and shielding performance.

- Aging Resistance: Over time, many materials deteriorate due to exposure to UV rays, ozone, and oxygen. Silicone, however, is highly resistant to aging, maintaining its physical properties and flexibility for long periods. This longevity ensures that the EMI shielding spiral tube continues to perform effectively even in long-term use, reducing the need for frequent replacements.

The excellent environmental adaptability of these tubes ensures that they can handle extreme conditions without sacrificing performance, making them suitable for industries where reliability and durability are crucial.

4. Improved Mechanical Stability

The combination of stainless steel’s strength and silicone’s cushioning effect provides superior mechanical stability. This hybrid design improves the overall durability and lifespan of the stainless steel EMI shielding spiral tubes with silicone cores.

- Stress Absorption: The silicone core acts as a buffer, absorbing mechanical stresses such as impacts, shocks, and vibrations. This reduces the potential for damage to the tube, helping it maintain its shielding and sealing properties over time. The cushioning effect also reduces the risk of cracking or wear on the stainless steel, enhancing the tube’s overall longevity.

- Protection Against External Forces: The flexible silicone core helps distribute forces more evenly, preventing localized damage to the stainless steel. This is particularly useful in industries such as automotive or aerospace, where components are exposed to high levels of mechanical stress, vibration, and thermal fluctuations.

- Reduced Wear and Tear: The silicone core helps to minimize the effects of wear and tear on the stainless steel tube, making it less prone to abrasions, cracks, or other forms of mechanical damage. This improves the long-term durability of the component, ensuring it continues to provide reliable EMI shielding and sealing over extended periods of use.

5. Easy Installation and Maintenance

The integration of a silicone core not only improves the tube’s sealing properties but also makes installation and maintenance easier. The flexibility and compressibility of the silicone allow for simpler handling, quicker installation, and less time spent on maintenance or replacement.

- Simplified Installation: Silicone is a highly flexible material, which allows the EMI shielding spiral tube to be compressed and easily fitted into tight spaces. The tube can be easily adjusted to the required length, and its flexibility ensures a tight seal with minimal effort. This makes the installation process more efficient, saving time and reducing labor costs.

- Maintenance and Replacement: The silicone core makes it easier to remove and replace the tube when necessary. If the tube becomes damaged or worn out, the process of replacing it is straightforward, thanks to the material’s flexibility. Additionally, silicone’s long-lasting properties mean that the tube requires fewer replacements compared to other sealing materials.

The ease of installation and maintenance is particularly advantageous in high-throughput industries where downtime must be minimized, such as in automotive manufacturing, aerospace, and electronics production.

6. Customization Options

Stainless steel EMI shielding spiral tubes with silicone cores can be customized according to the specific needs of various applications. Customization options include variations in size, material hardness, and the type of stainless steel used. Tailoring the tube to meet the exact requirements of a particular application ensures that the component performs optimally.

- Size Customization: These tubes are available in various diameters and lengths to suit the needs of different systems. Whether the requirement is for a small, compact tube or a larger, heavy-duty component, the tube can be tailored to meet those specifications.

- Silicone Hardness: The hardness of the silicone core can be adjusted to provide the right balance between sealing capability and flexibility. Soft silicone may be ideal for applications requiring tight seals under low-pressure conditions, while harder silicone might be better suited for environments with higher pressure or mechanical stresses.

- Material Selection: Different grades of stainless steel can be chosen based on the mechanical properties needed for a specific application. For example, a higher-grade stainless steel like 316L may be selected for applications involving harsh chemicals or extreme environmental conditions, while more common grades like 304 stainless steel may suffice for less demanding environments.

These customization options ensure that the EMI shielding spiral tubes with silicone cores are optimized for a wide variety of applications across different industries.

7. Wide Range of Applications

Stainless steel EMI shielding spiral tubes with silicone cores are used in many industries, particularly those requiring robust environmental protection and superior electromagnetic shielding. These tubes provide a unique solution for protecting sensitive electronic devices and systems in a variety of challenging conditions.

- Semiconductor Industry: In semiconductor manufacturing and testing, the tubes are used to shield sensitive components from electromagnetic interference, ensuring that the devices operate reliably in highly controlled environments. The sealing function also prevents contamination of the cleanroom environments, safeguarding the integrity of the devices.

- Medical Devices: Medical instruments, such as imaging systems and diagnostic equipment, rely on these tubes for protection against electromagnetic interference and environmental contaminants. The silicone core ensures that the tube remains sealed, even in challenging medical environments where hygiene and reliability are paramount.

- Aerospace: In the aerospace industry, these tubes are used in aircraft and spacecraft systems where components are exposed to extreme temperatures, mechanical stresses, and electromagnetic interference. The combination of stainless steel and silicone ensures that these systems continue to function in demanding conditions.

- Consumer Electronics: The tubes are also found in consumer electronics, including smartphones, tablets, and laptops, where electromagnetic shielding is needed to prevent interference from signals and maintain device performance.

8. Long-Term Reliability

The long-term reliability of stainless steel EMI shielding spiral tubes with silicone cores is one of their most important benefits. Their durability ensures that the tube maintains both its shielding and sealing properties for an extended period, reducing maintenance costs and improving the overall reliability of the system.

- Reduced Maintenance: The combination of stainless steel and silicone creates a durable, low-maintenance solution that can withstand years of use without significant degradation in performance. This reduces the need for frequent replacements, which is especially important in industries where downtime is costly.

- Consistent Performance: As long as the tube is not subjected to extreme external damage, it will maintain consistent EMI shielding and sealing performance throughout its lifecycle. This ensures that the equipment it protects remains operational, preventing costly system failures.

Conclusion

Stainless steel EMI shielding spiral tubes with silicone cores are an advanced solution for applications requiring both electromagnetic interference shielding and environmental sealing. The combination of stainless steel’s excellent shielding properties and silicone’s versatile sealing capabilities makes these tubes highly effective in protecting sensitive electronics in demanding environments. Whether in aerospace, medical devices, automotive systems, or consumer electronics, these tubes provide long-lasting protection and performance, ensuring the continued reliability and efficiency of critical systems.

Through their flexibility, environmental adaptability, and ease of installation, these tubes offer a comprehensive solution for a wide range of industries. As technology continues to evolve and become more complex, the demand for such advanced shielding solutions will only increase, making stainless steel EMI shielding spiral tubes with silicone cores an essential component for future applications.